|

|---|

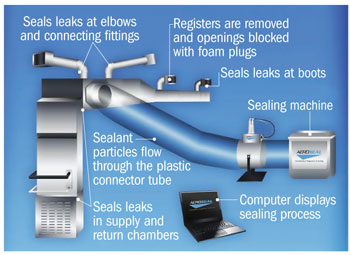

| Graphic courtesy of Aeroseal The illustration shows how the duct sealant fixes leaks from the inside. |

When a construction crew encountered a duct leak on the fifth floor of Memorial Sloan Kettering Cancer Center, New York City, it was important to get the problem fixed quickly.

Renowned for its excellent health care, Sloan Kettering leaders also make it a priority to operate the high-performing, LEED-certified building as efficiently as possible. A common problem in hospitals, duct leaks and the associated energy drain on the HVAC system represents money wasted.

To address this, Sloan Kettering facility staff chose a technology that plugs leaks using an aerosol-based adhesive mist that is blown into the inside of the duct system from an existing access point or temporary entrance into the ductwork.

The nontoxic sealant, made of vinyl acetate polymer, travels through the ductwork until it accumulates at a leak and plugs it. It reaches parts of ductwork otherwise inaccessible and without coating it, according to Centerville, Ohio-based Aeroseal, maker of the product.

Used by about 30 U.S. hospitals so far, the technology is effective at fixing 95 percent of leaks, states company officials.

Duct leaks are a common malady. According to the Department of Energy, duct systems in large medical facilities have leakage rates of between 12 and 30 percent.

It's estimated that a 15 percent duct leakage rate results in a 40 percent increase in fan power consumption, according to Lawrence Berkeley National Laboratory.

The aerosol-based duct sealing results in an average energy savings of 15 to 30 percent or more and limits the spread of airborne contaminants, Aeroseal states.

In Sloan Kettering's case, the product reduced leakage in one system from 8,729 to 613 cubic feet per minute (CFM). At an estimated $7 per CFM of conditioned air, the facility saves thousands annually, Aeroseal adds.