Using a well-tested technology that already treats a large portion of regulated medical waste (RMW) generated by hospitals, waste-handling autoclaves can safely be called a mature technology. Despite the equipment's lengthy history, however, vendors are still adding features to make RMW autoclaves safer and more efficient.

Using a well-tested technology that already treats a large portion of regulated medical waste (RMW) generated by hospitals, waste-handling autoclaves can safely be called a mature technology. Despite the equipment's lengthy history, however, vendors are still adding features to make RMW autoclaves safer and more efficient.

"The technology is tried and true. It works," says Laura Brannen, senior associate, materials and waste management prevention strategies, Mazzetti, San Francisco. "Recent improvements in technology have been in the handling of the waste. The equipment once was loaded manually. Today's systems are more automated. Material is conveyed directly into waste compactors."

Autoclaving still has limitations, according to Brannen. It does not take care of such hazardous materials as chemical waste, pharmaceutical waste and chemotherapy waste. However, autoclave technology continues to dominate the market because it is "approved by rule" in most states and the process is well-understood.

"Autoclave processing of RMW is economical and effective when properly managed. It is also safe, both in terms of operation and environmental impact," says Timothy Barrett, vice president and COO, OnSite Sterilization LLC, Pottstown, Pa. "Autoclave processing on-site allows hospitals to better control waste streams, reduces risks associated with the transportation of potentially infectious waste, and eliminates the cost and environmental impact of trucking."

On-site processing

Invented by French microbiologist Charles Chamberland in 1879, autoclaves use steam under pressure to eliminate the biological hazard of the waste in accordance with state regulatory requirements. By applying appropriate time, temperature and pressure conditions, the waste is heated sufficiently to render it safe for final disposal in an approved landfill.

Back in the 1990s, thousands of medical waste incinerators were used by hospitals. In 1995, Congress issued reports stating that incinerated medical waste was releasing mercury and dioxins into the atmosphere. That triggered a major shift in thinking.

After Congress passed the Clean Air Act in 1997, thousands of incinerators were forced to shut down nationwide, says Angel Aguiar, PE, vice president, Bondtech Corp., Somerset, Ky. Various non-incineration technologies then entered the market to fill the necessary capacity to replace the shuttered incinerators.

"Since the late 1990s, the trend has been to ship waste off-site," Brannen says. "However, the cost of shipping has increased. As a result, many hospitals are considering processing that waste on-site again. New technologies have come on board, but autoclave technology is what most hospitals will use."

On-site treatment can save thousands of dollars, lowering risk and decreasing dependence on third-party, off-site haulers. In addition, treating waste at the point of generation gives the hospital more control of its regulatory compliance.

"Many vendors are offering to bring their technology on-site to reduce costs," Brannen says. "The cost of shipping medical waste off-site can be as high as 45 cents per pound, compared with 1 to 2 cents per pound for shipping conventional garbage. Minus the shipping, it actually may cost less to do the processing on-site, despite the labor costs involved. Hospitals just have to weigh the total overall costs."

Arthur I. McCoy, senior vice president, San-I-Pak Inc., Tracy, Calif., touts many advantages to processing medical waste on-site. "From a clinical perspective, sterilizing potentially deadly pathogens at the point of generation is much safer than trucking this material to another location. From an environmental perspective, sterilizing infectious waste on-site produces fewer carbon emissions than does trucking the waste off-site.

"From an operational perspective, an in-house program to sterilize infectious waste can provide the hospital with operational sustainability during pandemic-crisis mode, especially if the transportation infrastructure is compromised. From an economic perspective, a well-designed, on-site program can be 70 percent less expensive than outsourcing to an off-site service provider."

By processing waste on-site, hospitals can realize cost savings that can result in a return on investment of one and a half to two years, says Aguiar. In fact, the life cycle of a properly engineered autoclave system can exceed 15 years.

Areas of automation

Waste autoclave technology has seen advances in the areas of automation, which reduces employee handling of waste, and more efficient use of energy and water. In addition, autoclave manufacturers are taking advantage of advances in computer technology to improve reliability and recordkeeping.

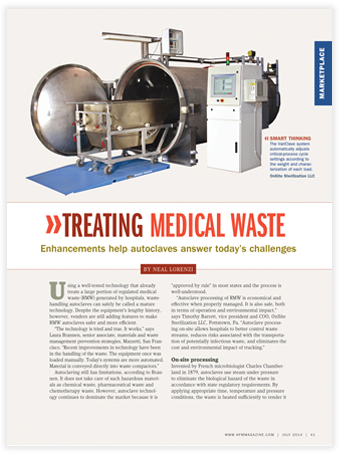

The VariClave system from OnSite Sterilization LLC automatically adjusts critical-process cycle settings according to the weight and characterization of each load, resulting in an economical process cycle, Barrett says. This offers advantages over fixed-cycle autoclaves. "Our unit is scalable to the needs of the hospital's waste stream and the VariClave comes in different sizes and materials, such as stainless steel or carbon steel." Featuring one-touch handling, the system is automated from the start of the cycle to completion.

The Mark-Costello Co., Carson, Calif., has been building high-pressure medical waste autoclaves since 1973. Its systems employ a liquid-ring vacuum pump, which is five times more efficient than a steam ejector, according to Michael Kelleher, vice president and partner. For efficacy testing, data loggers are placed in the center and bottom of the autoclave carts as well as inside sharps containers. "This provides real-time data to ensure that the correct temperature is achieved for the required spore kill and efficacy for every autoclave load cycle."

In addition, digital touch-screen controllers allow users to select from clearly defined menus. "Using a touch-screen interface increases operator accuracy, which reduces training time and improves operational efficiency, thus keeping costs down," Kelleher adds.

The latest waste autoclave from Bondtech Corp. includes a data logger with remote access to the Internet, a vacuum subsystem for waste treatment, low-water/zero-water process steam condenser and automated material handling subsystems. "The process steam condenser ensures minimal water consumption," Aguiar says. "All process steam is condensed and the condensate is safely drained to the sewer. By effectively controlling moisture release, the system eliminates nuisance odors and occupational exposure to autoclave process steam."

The Rotoclave dynamic autoclave from Tempico Manufacturing Inc., Hammond, La., features an internal rotating drum that accepts all unsorted RMW, tumbling the waste during the treatment process. This exposes 100 percent of the waste to the processing temperature and pressure, both during the pressurization stage while the vessel reaches the prescribed temperature and pressure, as well as during the time at temperature prescribed.

Because of the constant exposure of treated RMW to the prescribed temperature and pressure, the Rotoclave achieves Level IV microbial inactivation throughout 100 percent of the treated RMW, says William R. Sánchez, executive vice president and chief operating officer. "The system design allows a wide range of infectious and pathogenic materials to be treated above and beyond the typical hospital RMW treated in static autoclaves."

San-I-Pak has been manufacturing waste autoclave systems since 1978. McCoy says his company's technology continues to evolve as it interfaces with other health care technologies and hospital infrastructure. "The automation of our systems protects health care employees while minimizing human interface," he notes. "The technology has been designed and implemented at many new health care construction projects as a means of modernizing the hospital's overall waste management program." For example, San-I-Pak recently partnered its sterilization technology with advanced material-handling pneumatic and robotic systems.

Additional material-handling options offered by autoclave manufacturers include shredding and other size-reduction processes.

Other variations

Other variations using steam are available to serve the hospital market as well. They often shred waste during the steam-treating process.

The STI Series 2000 Commercial Medical Waste Treatment system from BioSAFE Engineering LLC, Brownsburg, Ind., was developed in 1995 and has processed in excess of 2 billion pounds of medical waste worldwide since then, according to Randall McKee, sales manager, medical waste products.

"Integral shredding of the STI system assures that all waste types (including bulk blood, urine, suction canisters and sharps) are steam-treated effectively," McKee says. "Shredding exposes the bags and their contents to direct steam impingement. It does not rely on conduction of steam to the center of the mass as do autoclaves."

Red Bag Solutions, Baltimore, has been supplying steam sterilization and maceration (SSM) equipment for on-site medical waste destruction over the past 18 years. The system uses a one-step process to macerate and sterilize simultaneously, chopping material into a confettilike substance; sterilization is guaranteed within 30 minutes. The processed waste is reduced by 90 percent and either can go directly to a landfill as municipal waste or can be repurposed or recycled, based on the material being processed.

"Besides the normal waste found in red bags, this technology can process suction canisters, sharps containers and their contents," says Bill Norton, executive vice president. "Because it is a closed system, there are no unpleasant odors or negative air emissions to deal with. The unit can be placed almost anywhere within a facility due to its compact size."

During the past year, Red Bag Solutions has developed an ozone sterilization and maceration system. "Ozone offers many advantages as a sterilant because of its strong oxidizing properties, which are capable of destroying a wide range of pathogens, including prions, without the need for handling hazardous chemicals," Norton adds.

Healthy head start

Experts agree that autoclave technology has evolved with the addition of programmable logic controllers and human-machine interface systems.

The technology will continue to advance with additional programming efficiency and will use less steam and water during the sterilization process, aiding what is already a healthy head start in the medical waste market.

"The medical waste market has been using non-incineration technologies for more than 30 years," Aguiar says. "Today, 95 percent of medical waste generated in North America is treated by steam autoclave systems."

Neal Lorenzi is a freelance health care writer based in Mundelein, Ill.

For more information

For further details on the waste management equipment featured in this report, contact the following vendors:

» BioSAFE Engineering

www.stibiosafe.com

» Bondtech Corp.

www.bondtechcorporation.com

» The Mark-Costello Co.

www.mark-costello.com

» OnSite Sterilization LLC

www.askonsite.com

» Red Bag Solutions

www.redbag.com

» San-I-Pak Inc.

www.sanipak.com

» Tempico Manufacturing Inc.

www.tempico.com