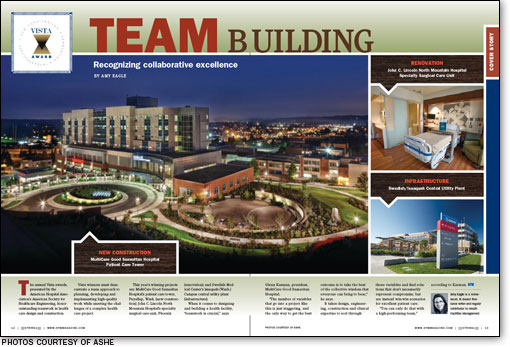

The annual Vista awards, presented by the American Hospital Association's American Society for Healthcare Engineering, honor outstanding teamwork in health care design and construction.

Vista winners must demonstrate a team approach to planning, developing and implementing high-quality work while meeting the challenges of a complex health care project.

This year's winning projects are: MultiCare Good Samaritan Hospital's patient care tower, Puyallup, Wash. (new construction); John C. Lincoln North Mountain Hospital's specialty surgical care unit, Phoenix (renovation); and Swedish Medical Center's Issaquah (Wash.) Campus central utility plant (infrastructure).

When it comes to designing and building a health facility, "teamwork is crucial," says Glenn Kasman, president, MultiCare Good Samaritan Hospital.

"The number of variables that go into a project like this is just staggering, and the only way to get the best outcome is to take the best of the collective wisdom that everyone can bring to bear," he says.

It takes design, engineering, construction and clinical expertise to sort through those variables and find solutions that don't necessarily represent compromise, but are instead win-win scenarios for excellent patient care.

"You can only do that with a high-performing team," according to Kasman. hfm

Amy Eagle is a Homewood, Ill.-based freelance writer and regular contributor to Health Facilities Management.

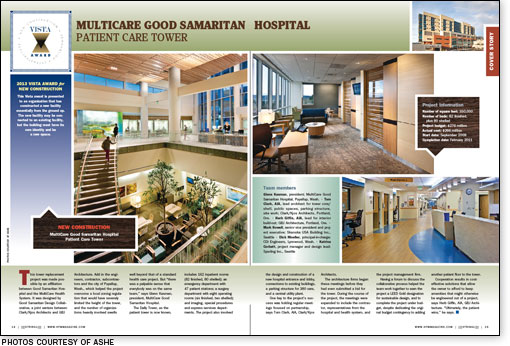

MultiCare Good Samaritan Hospital Patient Care Tower

2013 Vista Award for new construction

This Vista award is presented to an organization that has constructed a new facility essentially from the ground up. The new facility may be connected to an existing facility, but the building must have its own identity and be a new space.

Project information

Number of square feet: 350,000

Number of beds: 82 finished, plus 80 shelled

Project budget: $276 million

Actual cost: $266 million

Start date: September 2008

Completion date: February 2011

Team members

Glenn Kasman, president; MultiCare Good Samaritan Hospital, Puyallup, Wash. • Tom Clark, AIA, lead architect for tower core/shell, public spaces, parking structure, site work; Clark/Kjos Architects, Portland, Ore. • Herb Giffin, AIA, lead for interior build-out; GBJ Architecture, Portland, Ore. • Mark Howell, senior vice president and project executive; Skanska USA Building Inc., Seattle • Dick Moeller, principal-in-charge; CDi Engineers, Lynnwood, Wash. • Katrina Corbett, project manager and design lead; Sparling Inc., Seattle

This tower replacement project was made possible by an affiliation between Good Samaritan Hospital and the MultiCare Health System. It was designed by Good Samaritan Design Collaborative, a joint venture between Clark/Kjos Architects and GBJ Architecture. Add in the engineers, contractor, subcontractors and the city of Puyallup, Wash., which helped the project overcome a local zoning regulation that would have severely limited the height of the tower, and the number of organizations heavily involved swells well beyond that of a standard health care project. But "there was a palpable sense that everybody was on the same team," says Glenn Kasman, president, MultiCare Good Samaritan Hospital.

The Dally Tower, as the patient tower is now known, includes 162 inpatient rooms (82 finished, 80 shelled); an emergency department with 47 patient stations; a surgery department with eight operating rooms (six finished, two shelled); and imaging, special procedures and express services departments. The project also involved the design and construction of a new hospital entrance and lobby, connections to existing buildings, a parking structure for 380 cars, and a central utility plant.

One key to the project's success was holding regular meetings focused on partnership, says Tom Clark, AIA, Clark/Kjos Architects.

The architecture firms began these meetings before they had even submitted a bid for the tower. During the course of the project, the meetings were expanded to include the contractor, representatives from the hospital and health system, and the project management firm.

Having a forum to discuss the collaborative process helped the team work together to earn the project a LEED Gold designation for sustainable design, and to complete the project under budget, despite dedicating the original budget contingency to adding another patient floor to the tower.

Cooperation results in cost-effective solutions that allow the owner to afford to keep amenities that might otherwise be engineered out of a project, says Herb Giffin, AIA, GBJ Architecture. "Ultimately, the patient wins," he says.

John C. Lincoln North Mountain Hospital Specialty Surgical Care Unit

2013 Vista Recipient for Renovation

This award is presented to an organization that has altered the existing conditions or added new space to existing structures. The original building envelope must remain

Project information

Number of square feet: 21,350

Number of beds: 28

Project budget: $8.9 million

Actual cost: $8 million

Start date: July 2011 (build-out start date)

Completion date: December 2011 (substantial completion)

Team members

Sheila Gerry, senior vice president, real estate and facilities development; John C. Lincoln Health Network, Phoenix • Erin Kennedy, R.N., clinical project manager/charge nurse; John C. Lincoln Health Network, Phoenix • Javier Quesada, director of network construction; John C. Lincoln Health Network, Phoenix • Heather Ciszczon, IIDA, LEED AP ID+C, project engineer; DPR Construction, Phoenix • Marie Java, AIA, LEED AP, architect/project manager; Orcutt|Winslow • Shaun Grimm, electrical engineer; ccrd partners

To increase bed capacity at John C. Lincoln Health Network's North Mountain Hospital, an underutilized hospital floor was stripped down to its structural frame, then rebuilt as a 28-bed, post-surgery unit.

With construction occurring immediately above the hospital's surgical suite and post-cardiac care unit — which remained open throughout the project — the team was challenged to complete the renovation with minimal disruption to hospital operations. They also were required to squeeze modern health care infrastructure, including patient-lift supports, into a building older than 40 years with a floor-to-floor height of just 12 feet. The team also had a tight schedule to meet to open the unit in time for the hospital's high-volume winter season. The unit was open to patients in January 2012.

Integrated project delivery, three-dimensional building information modeling and a six-part phasing plan enabled the team to meet these demands while creating a unit that will serve as the health network's new facility design standard.

The core team, which met weekly, included the unit's charge nurse and representatives from the hospital's facility engineering, environmental services, security and information technology departments, in addition to hospital administration and design, construction and engineering professionals.

Synergy among team members brought out their creativity, says Sheila Gerry, the hospital's senior vice president, real estate and facilities development.

They demonstrated a collaborative spirit in many ways, from designers and builders personally visiting patients to discuss concerns about the project, to hospital executives purchasing magnetic bars from out-of-state IKEA stores during their vacations in order to help obtain the number needed to implement an inexpensive signage solution.

At the outset of the project, the team conducted an exercise in which participants described what they wanted to achieve with the renovation. In the end, "I think everybody felt they accomplished their goals, and it was a very successful project," says Bill Sheely, partner-in-charge, Orcutt|Winslow.

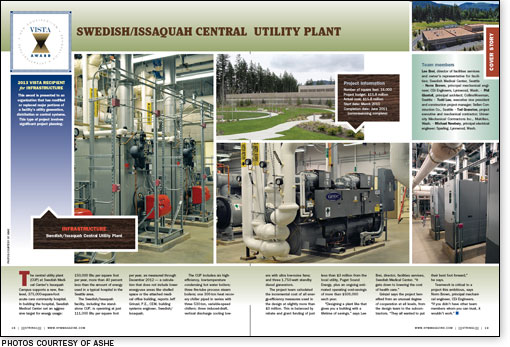

Swedish/Issaquah Central Utility Plant

2013 Vista Recipient for Infrastructure

This award is presented to an organization that has modified or replaced major portions of a facility’s utility generation, distribution or control systems. This type of project involves

significant project planning.

Project information

Number of square feet: 16,000

Project budget: $15.8 million

Actual cost: $15.8 million

Start date: March 2010

Completion date: June 2011 (commissioning complete)

Team members

Lee Brei, director of facilities services and owner's representative for facilities; Swedish Medical Center, Seattle • Norm Brown, principal mechanical engineer; CDi Engineers, Lynnwood, Wash. • Phil Giuntoli, principal architect; CollinsWoerman, Seattle • Todd Lee, executive vice president and construction project manager; Sellen Construction Co., Seattle • Ted Granston, project executive and mechanical contractor; University Mechanical Contractors Inc., Mukilteo, Wash. • Michael Newbury, principal electrical engineer; Sparling, Lynnwood, Wash.

The central utility plant (CUP) at Swedish Medical Center's Issaquah Campus supports a new, five-level, 375,000-square-foot acute care community hospital. In building the hospital, Swedish Medical Center set an aggressive target for energy usage: 150,000 Btu per square foot per year, more than 40 percent less than the amount of energy used in a typical hospital in the Seattle area.

The Swedish/Issaquah facility, including the stand-alone CUP, is operating at just 111,000 Btu per square foot per year, as measured through December 2012 — a calculation that does not include lower energy-use areas like shelled space or the attached medical office building, reports Jeff Grinzel, P.E., CEM, building systems engineer, Swedish/Issaquah.

The CUP includes six high-efficiency, low-temperature condensing hot water boilers; three fire-tube process steam boilers; one 300-ton heat recovery chiller piped in series with three 530-ton, variable-speed chillers; three induced-draft, vertical discharge cooling towers with ultra low-noise fans; and three 1,750-watt standby diesel generators.

The project team calculated the incremental cost of all energy-efficiency measures used in the design at slightly more than $3 million. This is balanced by rebate and grant funding of just less than $3 million from the local utility, Puget Sound Energy, plus an ongoing estimated operating cost-savingsof more than $500,000 each year.

"Designing a plant like that gives you a building with a lifetime of savings," says Lee Brei, director, facilities services, Swedish Medical Center. "It gets down to lowering the cost of health care."

Grinzel says the project benefited from an unusual degree of cooperation at all levels, from the design team to the subcontractors. "They all wanted to put their best foot forward,"

he says.

Teamwork is critical to a project this ambitious, says Norm Brown, principal mechanical engineer, CDi Engineers. "If you didn't have other team members whom you can trust, it wouldn't work."