Devising flexible hospital interiors (PDF)

Two recent projects by the New York office of architecture firm Francis Cauffman demonstrate the importance of flexibility to health care interior design.

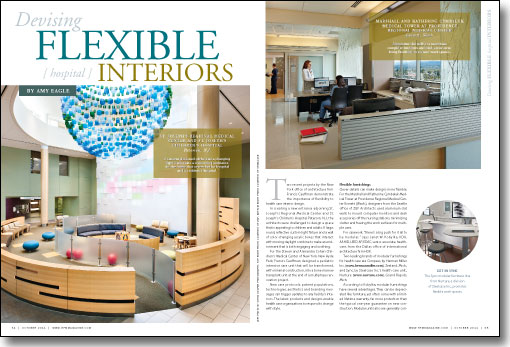

In creating a new entrance adjoining St. Joseph's Regional Medical Center and St. Joseph's Children's Hospital, Paterson, N.J., the architects were challenged to design a space that is appealing to children and adults. A large, round, reflective custom light fixture and a wall of color-changing acrylic boxes that interact with moving daylight combine to make an environment that is both engaging and soothing.

For the Steven and Alexandra Cohen Children's Medical Center of New York, New Hyde Park, Francis Cauffman designed a pediatric intensive care unit that will be transformed, with minimal construction, into a bone marrow transplant unit at the end of a multiphase renovation project.

New care protocols, patient populations, technologies, aesthetics and branding messages can trigger updates to any facility's interiors. The latest products and designs enable health care organizations to respond to change with style.

Flexible furnishings

Clever details can make designs more flexible. For the Marshall and Katherine Cymbaluk Medical Tower at Providence Regional Medical Center Everett (Wash.), designers from the Seattle office of ZGF Architects used aluminum slat walls to mount computer monitors and desk accessories off the nursing stations, minimizing clutter and freeing the work surfaces for multiple uses.

For casework, "there's a big push for it all to be modular," says Janet W. Kobylka, IIDA, AAHID, LEED AP, EDAC, senior associate, healthcare, from the Dallas office of international architecture firm HOK.

Two leading brands of modular furnishings for health care are Compass, by Herman Miller Inc. (www.hermanmiller.com), Zeeland, Mich., and Sync, by Steelcase Inc.'s health care unit., Nurture (www.nurture.com), Grand Rapids, Mich.

According to Kobylka, modular furnishings have several advantages. They can be depreciated like furniture, yet often come with a limited lifetime warranty, far more protection than the typical one-year guarantee on new construction. Modular units also are generally constructed better, she adds, because the designs are refined by furniture manufacturers who carefully consider elements like joinery, weight loads and durability. The manufacturing process can be more sustainable on a larger scale. And there is less waste, financially, environmentally and operationally, in terms of downtime when renovations occur, because facilities can easily relocate the product. "It's a long-term savings," says Kobylka.

Headwall and footwall solutions

The Elements headwall system from Hill-Rom Company Inc. (www.hillrom.com), Batesville, Ind., is configurable, scalable and acuity adaptable. One of the primary features of the Elements headwall is a manifold located behind a series of removable panels. The manifold connects to flexible hoses that allow a hospital to reposition or add gas outlets easily, "without shutting down an entire floor, calling in lots of contractors and taking rooms out of commission," says Dennis Gallant, director, product and design, innovation patient environment, Hill-Rom.

The outlets have no faceplates, making the headwalls easy to wipe down, and they are simple and clean to install, either on an existing wall or in a space-saving, back-to-back configuration for adjoining rooms. A variety of design choices and workflow components can be used to create a custom solution for any facility.

Hill-Rom also offers the Elements footwall system, which includes options for patient wardrobes, lighting, dry-erase boards and similar features. A patient lift can be integrated into the Elements footwall to make the lift less conspicuous.

Pure genius

The Genius movable architectural wall system from KI (www.ki.com), Green Bay, Wis., provides a similar system of panels that can be removed to access power and data or replaced to create a new look using a different substrate or finish. The modular system can be reconfigured easily. According to Rob Wittl, senior product manager for KI movable walls, the Genius wall system in the registration area of the University of Miami Health System's Sylvester Comprehensive Cancer Center has been revised 35 times in the past five years to accommodate various image, branding and operational changes.

Genius walls have several features well-suited to health facilities, says Debbie Breunig, vice president of health care, KI. They are designed to reduce noise to protect patients' rest and privacy. Glass panels promote daylighting and make patients clearly visible to staff, for a safer, more sustainable healing environment. The installation process is much cleaner than conventional construction, with less infection risk from dust and little off-gassing of volatile organic chemicals from paints and finishes. The recycled aluminum and steel materials are durable and recyclable, for an environmentally responsible product life cycle. And KI's sliding doors are easy to use and require a smaller building footprint than standard doors; this can create substantial savings in floor area.

Genius products are warranted for 10 years, with a 10-year nonobsolescence agreement, to manage changes far down the road.

Doing it right

DIRTT Environmental Solutions (www.dirtt.net), Calgary, Alberta, Canada, takes its name from the phrase, "doing it right this time." The company's comprehensive line of agile architectural products — doors, walls, flooring and accessories — are designed to be durable, cleanable, sustainable and flexible to use. "It's clean construction for the interiors. We don't have to guess what the demographics, technology, care paths or even the acuity level of the space are going to be over time," says Kristin J. Moore, LEED AP, DIRTT.

DIRTT walls can be customized with support for medical gases and equipment, plumbing, power and data, handrails, furniture, storage and audio/visual systems. A large number of finishes, including fabric, glass, veneers and Corian solid surface material from DuPont (www.dupont.com), Wilmington, Del., are available.

With ICEcycle product life-cycle management software from DIRTT subsidiary Ice Edge Business Solutions, users can reconfigure layouts digitally, tracking which pieces can be reused in a new design and how much money the organization is saving through reuse. DIRTT products can be rearranged without creating hazardous drywall dust or material-wasting debris.

Moore notes that change can be so painful to implement in occupied spaces, hospitals often will not do it. "It's just too much of a disruption to the staff, to the patients. So the interiors get further and further and further behind. It ultimately becomes cheaper to tear down the building and start from scratch. Let's stop treating our interiors like a disposable element," she says.