|

|

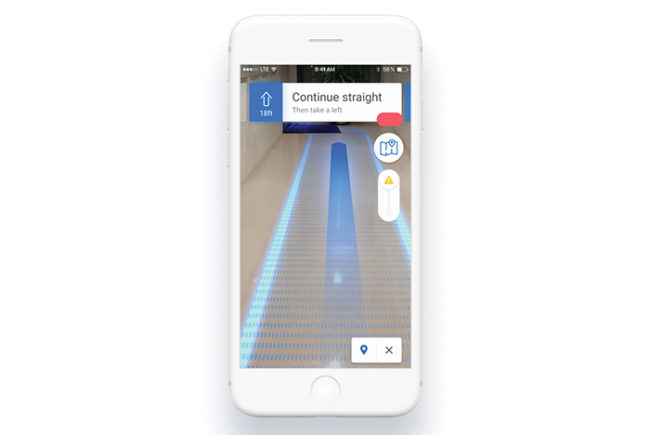

Using mobile devices to check the status of construction on Grandview Medical Center are project managers Virnetta Woodbury (left) and Susan Stabler. Photo courtesy of Brasfield & Gorrie |

When general contractor Brasfield & Gorrie, Birmingham, Ala., was picked to finish building a hospital it had started working on after a 10-year layoff, it jumped at the chance.

Despite the challenges related to the gap in time, the company is benefiting from advances in technology that have made the second round on the job easier, safer and more cost-effective.

Last August, Brasfield & Gorrie resumed construction of a new 12-story, approximately 1 million-square-foot hospital in Birmingham that it began in 2002. Work stopped in 2003 when the previous owner experienced financial problems.

The construction firm had completed the infrastructure, shell and five floors of interior space before the project was shut down. The site lay dormant while the facility's future was determined in court.

When new owner Trinity Medical Center, also in Birmingham, won the rights to finish the hospital, it picked Brasfield & Gorrie to complete the 372-bed facility, now known as Grandview Medical Center. The project also includes a 220,000-square-foot medical office building and 2,900-space parking deck.

"The sequence in which this job was originally finished and then left with little maintenance for more than 10 years has presented a significant challenge," says Susan Stabler, Brasfield & Gorrie, senior project manager.

The first steps were to conduct a seven-month retrocommissioning of existing systems before renovating the fifth though ninth floors. It also started construction on the top two floors, leaving the 12th floor vacant for possible future expansion.

The company is using the latest design software to convert the original blueprints and replicas of the project into one unified 3-D digital model that can be shared by project team members on mobile devices. The company had the entire 15-acre jobsite Wi-Fi-enabled as an additional way to maximize communication and cut costs.

"When the project was halted in 2003, the team had spent nearly $1 million on blueprints. Today we expect to spend less than $75,000 on technology and printing combined," Stabler says.

The company is using a camera-equipped robot crawler that can climb the side of the facility to check the condition of the exterior skin. Auburn University students also are operating drones with cameras to inspect the quality of the exterior as part of a research project on the use of the technology on a construction site.

The company expects to complete the project in early 2016.