Health care facilities managers must consider a number of factors when it comes to installing and using emergency power generators. When hospitals cannot maintain power, they place the lives of patients, employees and visitors at risk. Loss of communication is another concern, as is loss of key data. In addition, the impact of major weather events, such as Hurricane Katrina, has shined a spotlight on a complex situation.

Moreover, as the health care industry moves to a hub-and-spoke model to provide more localized care, there is an increasing need for backup power at off-site facilities, thus ensuring that critical procedures are not interrupted in the event of a utility outage.

You may also like |

| Emergency power system commissioning |

| Backup power requires correct connectivity |

| Six areas of emergency power management |

| |

Government regulations are in place to make sure that off-site facilities have emergency power-generation equipment available, be it on a smaller scale. “Ambulatory surgery centers are required by local and state codes to have emergency power,” says Dan Chisholm Sr., president and emergency power consultant/designer, MGI Consulting Inc., Winter Park, Fla. The same National Fire Protection Association (NFPA) 110 standards apply to these locations as for a Level I trauma center. Emergency power must be available within 10 seconds to Life Safety and Critical Branch loads if a utility failure occurs. These same standards apply to some limited care and long-term care facilities.

Location, location, location

Generators, switchgear and fuel systems should only be installed in hospital locations where they are protected from inclement weather, floods, earthquakes and fire, according to Chisholm. “This requirement rules out most basement and rooftop placements. Also, administrators must decide what services they are required to provide per agreements with other hospitals, state and local municipalities and for how long, in the case of an extended utility outage.

“This could dictate the type of fueling system options (natural gas, diesel or a combination of both) and tight compliance with EPA Tier 4 regulations on the latest diesel engine designs. Contrary to popular belief, the newer natural gas- and propane-powered sets can be used on selected projects in several states.”

Health & Human Services has released a report on “Hospital Emergency Preparedness & Response During Superstorm Sandy” that urges hospitals to collaborate with others. “The experiences of hospitals during Superstorm Sandy and the deficiencies cited prior to the storm reveal gaps in emergency planning and execution that might be applicable to hospitals nationwide. Insufficient communitywide coordination among affected entities was a common thread through the challenges identified by hospital administrators,” the report states.

In the report, HHS recommends that the Office of the Assistant Secretary for Preparedness and Response (ASPR) continue to promote federal, state and community collaboration during major disasters. The agency also recommends that the Centers for Medicare & Medicaid Services (CMS) examine existing policies and provide guidance regarding flexibility for reimbursement under disaster conditions. ASPR and CMS concurred with those recommendations.

Hospitals typically require multiple generators because of their size and the importance of power to overall operations. “As a result, paralleling switchgear is important to meet their sequence of operation. Switchgear — tailored to specific needs — provides hospitals with the ability to control power for their existing load while ensuring that they’re covered for unforeseen events,” says Michael Bosela, senior field applications engineer, Kohler Power Systems, Kohler, Wis.

A key paragraph in NFPA 110 requires that hospitals restore power to essential life safety loads in 10 seconds or less. In California, the Office of Statewide Health Planning and Development (OSHPD) requires seismic testing of generator equipment on a shake table to replicate an actual event. “Although the governance of OSHPD is in California, an increasing number of outstate health care facilities are including this requirement for their generator sets and other power system equipment,” says Luke Dewey, marketing manager, Cummins Power Generation, Fridley, Minn.

“Also, hospitals typically are located in high-population areas and residential zones. These communities are expected to demand more stringent sound-level requirements from the generator-set equipment over time,” Dewey adds.

Technical advances

Governmental regulations are intertwined with new developments in generator technology, according to manufacturers that supply the nation’s hospitals. “As EPA emissions requirements have evolved since 2006, advanced fuel delivery systems had to be engineered into engines to meet these exhaust requirements. Now technology has worked its way back onto the generator itself,” says Daniel Barbersek, director of industrial sales, Generac Industrial Power, Waukesha, Wis. One example, he says, is the ability to record and report generator operations.

Another technological advance is the ability to parallel with other generators, which is done to promote both redundancy and generator capacity. “The ability to control paralleling units right at the generator, instead of using paralleling switchgear, increases reliability by narrowing things down to a single point of failure. Cost always has been a major hurdle when using switchgear, as each section of paralleling gear can cost as much as $60,000,” Barbersek says.

Most technological advances in generator engine and alternator design during the past 10 years involve controls, according to Brian Ponstein, regional sales engineer, MTU Onsite Energy Corp., Mankato, Minn. “The monitoring and controlling features of generators have allowed operators to understand and do much more with their units. The controllers also have increased the capability of onboard paralleling features to reduce the need for expensive switchgear.”

MTU has incorporated low-load operation mitigation and better fuel economy into its latest generators. This allows the systems to run longer and hold up to the varying loads a typical emergency power system experiences. “MTU achieves better fuel economy by optimizing in-cylinder technology and utilizing a high-pressure, common rail fuel system,” Ponstein notes.

Cummins Power Generation offers a range of generators for hospital applications that meet EPA Tier 4 final emissions requirements through a combination of in-cylinder and exhaust after-treatment technologies. This is EPA’s most stringent emissions requirement for stationary generator sets, the company reports.

The latest generator-set controllers from Kohler Power Systems are robust, intuitive and easy to use, according to Bosela. “We offer generator-set controllers to parallel and load manage different types of fuel systems. For example, paralleling a 500-kilowatt (kW) diesel generator with a 200-kW natural gas generator is a relatively simple process. Our customers also have the ability to add different size generator sets to expand their system as their facilities grow.”

During the past 10 years, technological advances that have delivered the greatest gains in reliability relate to testing and services that ensure that the complete electrical system is healthy, according to Brian George, corporate account manager for data center and health care markets, Caterpillar, electric power division, Peoria, Ill. Examples include load bank testing, megohmmeter testing that provides an accurate conditional analysis of the alternator or transfer switch, as well as fuel and starting battery testing and monitoring.

Caterpillar is focused on providing sustainable solutions beyond emergency diesel backup, George adds. “Our natural gas generator-set product lineup offers high efficiency up to 4 MW [megawatts], which plays well into load management and cogeneration applications. Cogeneration can provide system efficiencies in the 85 to 90 percent range.

“We see more demand from hospitals for integrated emergency power systems from a single supplier — everything from the generator set to the paralleling switchgear/controls/automatic transfer switch to the uninterruptible power supply. We also see more interest in natural gas solutions for load management and cogeneration, which leverages waste heat from the generator-set package for facility heating or the production of chilled water,” George notes.

More dual-fuel generator units, which run on diesel fuel and natural gas, are being used in hospitals, experts agree. The big attraction of this technology is extended run times. The health care facility is able to enjoy the benefits that an endless fuel supply of natural gas brings without exposure to disruption that a utility connection brings. “This approach also gives facilities managers the ability to maintain a smaller amount of on-site diesel fuel,” says Barbersek.

Dual-fuel sets actually can double the time a hospital stays on emergency power, experts agree. Also, if a natural gas connection is shut off, the generator can still run on full diesel, which makes for a win-win situation.

Connecting nonessential loads such as HVAC and lighting to the essential emergency power distribution system has been an ongoing trend in the health care industry. The National Electrical Code has allowed nonessential loads to be serviced by the emergency power system for years. However, there is ongoing discussion to determine which loads should be served by the emergency systems, experts agree. In fact, the new trend is to review what loads need to be served by emergency systems during an extended outage. Many loads once considered nonessential for short-term outages now are being re-evaluated as to the criticality of the function.

Looking ahead

Manufacturers see additional technological advances in the near future. Better reporting and self-analysis when it comes to trouble shooting is on a fast track as well as mean time between repairs, according to Barbersek. “There also is discussion on participating in utility load-curtailment programs; however, emissions requirements continue to be a major barrier,” he says.

Over the short term, developments in technology will continue to minimize generator emissions while making the units easier to operate and manage, according to Bosela. “You can expect generator manufacturers to further enhance their controllers to offer a new level of intelligence that will integrate seamlessly into building automation systems.”

Dewey expects to see increased remote monitoring of equipment in an effort to optimize maintenance of the power system. “Advances in remote monitoring will allow users and technicians to respond more quickly to equipment issues and provide maintenance based on actual usage of the equipment,” he notes.

George sees growing interest in natural gas generation for load management and cogeneration. “As distributed generation — energy generated at the point of consumption — grows as a percentage of overall U.S. capacity, health care facilities will be a natural fit for leveraging gas generator-set technology to better manage electricity, heating and cooling costs. Condition monitoring and maintenance of these emergency/load management power systems will be a critical element in lowering costs and increasing reliability.”

Chisholm sums up: “The bottom line is that emergency power must be available 24/7, at any time the utility suffers a failure, and it must be available to life-supporting loads within 10 seconds for as long as the utility outage lasts.”

Neal Lorenzi is a freelance writer based in Mundelein, Ill.

| Ready for actionFour Series 4000 generator sets, each producing 2,250 kW, and paralleling switchgear offer emergency standby power to Nemours Children’s Hospital in Orlando, Fla. |

| Clutch supportGenerators provide backup power at Cancer Treatment Center in Atlanta. |

| Two to oneTwo generator sets, two controls and one automatic transfer switch illustrate the manufacturer’s Power of One offerings. |

| Sound systemEdward Hospital in Naperville, Ill., uses two Cat 3516 diesel generator sets with a dual-silencer system and paralleling switchgear to meet power generation and sound requirements. |

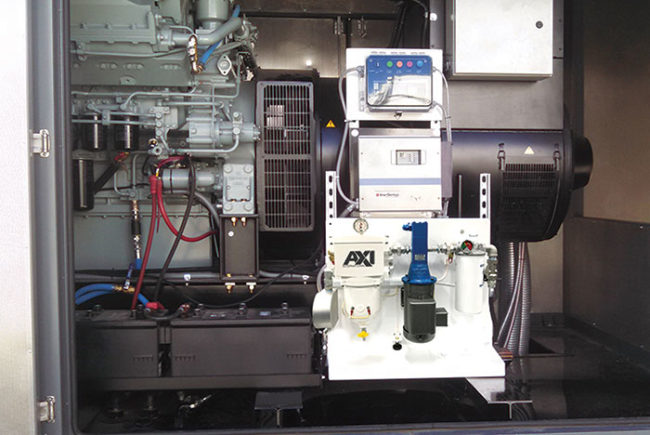

| Future functionsOngoing advancements on generators such |