On May 22, 2011, St. John's Regional Medical Center, Joplin, Mo., was torn apart by a violent tornado. "The hospital was hit directly," says John Farnen, executive director of strategic projects for Mercy, the health system that operated the hospital. "Walls were blown in, elevator shafts blown apart."

The day after the storm, Mercy made the decision to rebuild, Farnen says. Less than a year later, they had.

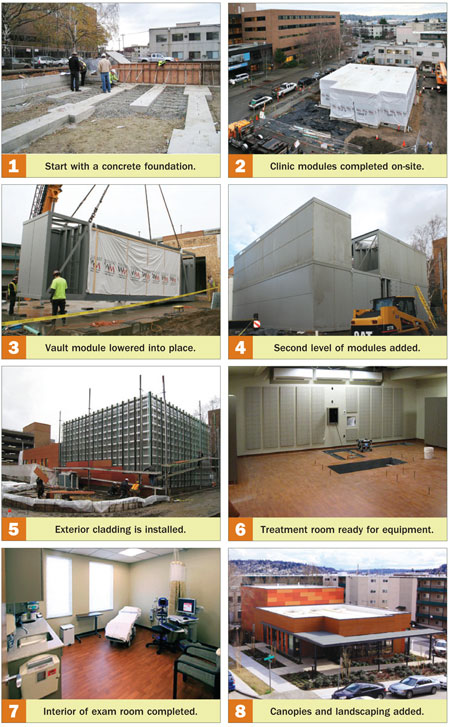

The following April, Mercy opened a component hospital that the health system is using as an interim facility while the organization completes a much larger rebuilding project for its growing community. The 150,000-square-foot, two-story component hospital was designed and built in eight and a half months by Aspen Street Architects, Angels Camp, Calif., and Walden Structures, Mentone, Calif. "I've been doing design and construction a long time," says Farnen. "But eight months? I didn't think that was even possible."

The hospital is made of 224 structural steel components built in Walden Structures' California factory and shipped by train and truck to Missouri. The modular units already were under construction as the Joplin site was cleared and foundations and underground utilities were installed.

With modular construction and prefabrication, "the speed to market is incredible," says Jim Poole, senior vice president, construction and engineering firm Robins & Morton; prefabrication helped the firm to build MaineGeneral Health's 640,000-square-foot Alfond Center for Health, Augusta, Maine, in less than 25 months. And the quality of components built in a controlled environment can be "superior" to those built in the field, adds Ken Fennell, LEED AP, division manager of preconstruction, also of Robins & Morton.

A growing number of health professionals are turning to modular construction as an efficient means to create quality facilities. "It's definitely here to stay," says Chip Cogswell, national health care director, Turner Construction Co., New York City. "Anybody who's not doing it isn't paying attention."

|

|

Overhead mechanical equipment was manufactured off-site, trucked to the building site, lifted by crane and moved by hand cart to be mounted over the central corridors of the patient floors for a neuroscience institute and patient tower project by NBBJ and Whiting Turner at OhioHealth’s Riverside Methodist Hospital, Columbus, Ohio. Photo © Norman Ai/NBBJ |

Off-site advantages

According to the Modular Building Institute, an industry trade group, modular construction is the process of building a structure off-site, under controlled conditions, using the same materials, codes and standards as conventionally built facilities, in about half the time. Buildings are produced in modules that, when put together on-site, reflect the design intent and specifications of the most sophisticated traditionally built facility, says Tom Hardiman, CAE, executive director, Modular Building Institute.

Prefabrication is the process of assembling smaller building components in a factory setting and transporting them to the building site for installation, explains Andrew Quirk, senior vice president and national director of construction and development company Skanska's Healthcare Center of Excellence.

When building under controlled conditions, quality goes way up, says Quirk. The off-site setting is a safer, more comfortable work environment that tends to attract the best workers, he says. It also can provide quality assurance opportunities that may not be available at the hospital site. For example, work crews can monitor connections on a factory-built building facade to make sure joints are tight and waterproof, making it less likely the joints will fail in the field.

"With a production line, you can work out bugs early," comments Mark Taylor, vice president of permanent modular construction for PCL Construction, an international group of independent construction companies. This is especially important for repetitive parts of the design, like patient rooms and bathrooms. If a design calls for 200 rooms, "you can build 200 right," particularly if you aren't working with several different framing, plumbing and drywall crews, he says. "The more variables you have, the harder it is to have a consistent product," Taylor notes.

Off-site construction allows for greater use of manufacturing technologies like laser cutters and computer-guided machines that can ensure each measurement is true. "If the gas outlets are supposed to be 54 inches above the floor, they'll all be in a line, exactly," says Matt Palmer, director of marketing for Modular Services Co., an Oklahoma City-based firm that manufactures and services prefabricated health care products, including headwalls, footwalls, sinkwalls, columns and boom systems.

Third-party vendors can provide expertise on specialized components. Palmer says his company's products are meant to benefit not only the construction process, but hospital operations. "We've been designing and producing prefabricated headwalls since the '70s," he says. "We view this as a piece of medical equipment." Purchased components can provide high-quality engineering and aesthetics, with a number of finishes and other design options available. Customers are no longer limited to "the gray one or the other gray one," Palmer laughs.

Another company in the market, Blox, Bessemer, Ala., builds prefabricated bathrooms, headwalls and exam rooms for health care facilities.

The plug-and-play nature of installing components in a facility makes the construction process more certain, because project teams can plan for the arrival of completed units at the building site. This reduces change orders in the field, says Palmer.

The inspection process for a modular project can require more teamwork with inspectors up front, so they understand how the design will be executed. On the Mercy Joplin project, for example, the design and construction team worked closely with state and local authorities having jurisdiction, and Mercy employed a full-time inspector at the factory in California to ensure compliance with Missouri building codes.

In general, inspectors love the process because they can see the level of quality, says Quirk. Components are easier to examine in a factory, where 360-degree views are possible, than they are above a hospital ceiling, he notes.

|

|

Swedish Medical Center created a permanent radiation treatment center on the organization’s Ballard, Wash., campus using a modular vault by RAD Technology Medical Systems. The 3,995-square-foot project was installed in less than 30 days. Photos courtesy of RAD Technology Medical Systems |

Potential savings

Some fixed costs for the construction of modular components are not necessarily lower than those for a traditional project — after all, the materials are the same, says Cogswell of Turner Construction, and the prefabricated components need to be shipped to the facility site — but the process can provide better value overall. The factory building environment makes efficient use of labor and materials and can help to shorten the duration of a project, all of which can add up to significant savings.

In addition, buildings designed and built in a modular fashion are inherently adaptable, an essential quality in health care facilities as the Affordable Care Act comes into focus, says Quirk. "There is still a ton of uncertainty left and that translates to the built environment," he says. Facilities that allow providers to respond swiftly to changing conditions provide a better return on investment.

RAD Technology Medical Systems, Aventura, Fla., designs, installs and finances modular radiotherapy vaults and clinics. The company's modular vaults utilize a patented, removable granular fill technology for shielding, replacing more than 2 million pounds of poured concrete. This allows the buildings to be built quickly, upgraded easily or relocated. Providers can get a clinic up and running in a couple of months for interim or permanent use. They also can lease for as little as 90 days a temporary vault that can be installed in five days.

University of Michigan Hospitals and Health Centers (UMHHC) is using a RAD PRO vault structure and clinic to retain patient volume as the organization takes each of its radiotherapy rooms offline for equipment upgrades. Donald Wesley, AIA, LEED AP, senior architect, UMHHC, says, "Even though it's modular, it looks like a facility that belongs on a campus."

By leasing the PRO for seven years, UMHHC can maintain revenue while minimizing capital expenditure, because the cost of the building is an operational expense. "Modular does things traditional construction could never do," says John Lefkus, president, RAD Technology Systems. "It's a way to stay competitive, handle upgrades or expand without capital."

Modular thinking can lead to innovative cost-saving measures, like the pedestrian walkway created from prefabricated pieces purchased from a jetway manufacturer in the construction of Miami Valley Hospital (MVH) Heart and Orthopedic Center, Dayton, Ohio. Tim Fishking, AIA, design firm NBBJ, explains that the pedestrian bridge was needed as a temporary bypass around two buildings that were razed to clear the site. Building the bridge in a conventional manner would have cost approximately $2.1 million and could have disrupted traffic at the hospital's main entry for four to six months.

The jetway solution cost $980,000 and was installed in three days, without disrupting hospital operations.

Function and aesthetics

The MVH project team was inspired to develop the jetway solution in part because they were already working on a modular design for the hospital tower. The owner, Premier Health Partners, was interested in modular design as a means to create a standardized environment of care for increased safety and efficiency, says Ryan Hullinger, AIA, principal, NBBJ. Approximately 35 percent of the project was built off-site, including the components of 178 identical same-handed, acuity-adaptable patient rooms. When further study indicated that the rooms were too large to transport as single units, the project team divided each room into three separate sections — toilet room, headwall/footwall and casework — to be constructed remotely and then assembled on-site.

"We wanted the prefabrication process to serve the design, rather than having the design serve the prefabrication," says Hullinger. "We didn't want the idea of prefabrication to drive functional or aesthetic decisions." As a result, says Fishking, in the majority of the building "there's no trace of its innovative construction process. There's no way for anyone to tell which components were built off-site."

An important exception to this is the overhead utility racks, which were loaded in a notably well-organized fashion due to their off-site construction. "What they have above the ceiling looks more like a Swiss watch than the spaghetti you usually see," Hullinger says. The utility system will be easier to track and repair, add to or modify, which will contribute to the longevity of the building, he notes.

Fishking says some previous clients of the firm have wanted to explore the idea of same-handed and acuity-adaptable rooms, but could not afford the cost premium that can be associated with building these designs. With the savings that off-site construction can bring, clients can do more with a project, whether that means more space, more equipment or more features, Hullinger says.

NBBJ is currently partnered with OhioHealth and construction manager Whiting-Turner on the design-build of a neuroscience institute and 224-bed patient tower at Riverside Methodist Hospital, Columbus, Ohio. The construction schedules and budget were built around the projected savings of a modular approach, and the team is collecting detailed metrics to determine the final value to the project, Fishking says.

Hallmarks of process

"The economy has hit everybody hard, particularly health care institutions. We're working hard to help them respond to the new economy, and a lot of that's being driven by cost," Fishking says.

"But it's also being driven by needing to maintain competitiveness and getting to market very quickly, without any sacrifice to quality," he adds. "That's what we feel are some of the hallmarks of this process."

Amy Eagle is a freelance writer based in Homewood, Ill., who specializes in health care-related topics. She is a regular contributor to Health Facilities Management.

Parallel processes keep construction projects moving

In computing, parallel processing executes programs faster by dividing the work among multiple processors. Modular construction and prefabrication bring a similar efficiency to health facility projects.

Standard, stick-built construction is a very linear process; introducing a secondary location for component production allows project teams to schedule a lot more work to be completed in the same time frame, says Mark Taylor, vice president of permanent modular construction, PCL Construction Enterprises Inc., Denver.

This can shake up the decision-making process for designing a facility. According to Andrew Quirk, senior vice president and national director of construction and development company Skanska's Healthcare Center of Excellence, certain questions may seem out of sequence to people who are new to this type of construction. Finish selection, for example, needs to occur earlier than usual.

But the time savings can be significant. Working in a modular fashion, projects can be completed up to 30 percent faster, says Quirk. For facility owners, "that equates to significant revenue above and beyond what they were counting on in their financial plans," he says. "It adds ROI to your facility immediately."

The assembly-line construction process is very efficient. Compared with building in the field, the work area is safer, more ergonomic and, as Chip Cogswell, national health care director of Turner Construction Co., New York City, points out, neither too small (multiple crews aren't forced to work in a constrained space like a patient bathroom) nor too large (people don't have to haul drywall and studs up 10 stories).

Rudy Lonergan, RA, EDAC, CHC, LEED AP, director of facilities development, Northeast Georgia Health System, says his organization is realizing these benefits in the construction of Northeast Georgia Medical Center Braselton, a greenfield hospital due to open May 2015. While the health system is paying a small premium to have the headwalls and toilet rooms for the hospital's 100 patient rooms prefabricated off-site, it is estimated this will shorten the schedule by two months.

"It's about $30,000 more than what we would have paid for standard construction, but we'll recoup that many times over," says Lonergan. Additional benefits include higher quality from constructing in a controlled environment, a cleaner and safer job site and complete recycling of all construction waste, he says.

Modular construction improves safety and sustainability

Modular construction and prefabrication can increase the safety and sustainability of health facility projects.

"On a traditional construction project, you have multiple trades on the job site," says Andrew Quirk, senior vice president and national director of construction and development company Skanska's Healthcare Center of Excellence. The work environment can be crowded, with electrical cords snaking underfoot and people operating power tools overhead. Adverse weather conditions also can create hazardous situations.

Contrast this with the controlled, ergonomic environment of an off-site, modular factory setting, where tradespeople can work from a standing, waist-high position or while seated. With a modular approach, "a lot of the hazards associated with construction have been removed," Quirk says.

These include hazards to patients, visitors and staff at a hospital that is undertaking a renovation or expansion project. With most of the construction work taking place off-site, much of the associated noise, dust and vibration occurs away from the facility. Also, compressing the duration of on-site building activity can streamline phasing plans significantly, which can be challenging for health care organizations to develop and execute.

"That's why we're bringing prefabrication to our renovation work. You can actually build many of the major components in a shop off-site before you even begin demolition," says Ryan Hullinger, AIA, principal at design firm NBBJ. "Then all of those prefabricated rooms are ready to plug in, in a matter of weeks rather than a matter of months, significantly reducing the hospital's downtime for that unit."

By ordering materials sized to project specifications and using nesting software to optimize the amount of material used from a single piece, builders can reduce the volume of scrap that ordinarily makes its way to a landfill from a construction site. The controlled factory environment also can contribute to less accidental breakage.

Quirk says he has seen a modular job that ended up filling just one dumpster, primarily with packaging material, as opposed to the multiple dumpsters a day that are generally hauled from a building site. Environmental sustainability was not originally one of the benefits Skanska thought to achieve with modular construction, but the method's impact in this area "is pretty inspiring," he says.