Light-emitting diode (LED) technology is being embraced by more health facilities professionals because of the advantages it provides, including energy savings, easy maintenance, controllability, visual acuity and integration with building automation systems.

“LED lighting is the biggest innovation to happen in years and the technology continues to advance at a rapid pace,” says Deb Zawodny, central regional sales manager, architectural ambient/health care, Eaton, Peachtree City, Ga. “The IES TM21 testing methods [for predicting useful LED life] have made it easier for facilities managers to have reliable data to reference when choosing LED lighting. Manufacturers continue to strive for improved fixture and component designs, resulting in fixtures that are even more energy-efficient and durable but lighter and easier to install and maintain.”

Two major trends in the evolution of LED technology are certifications for more stringent applications and conditions, and the integration of controls, according to Pat Treadway, product marketing director–indoor, MaxLite, West Caldwell, N.J. “As lighting moves into the realm of a system more than a stand-alone device, entire wings and even individual beds can be dimmed, lit or color-changed,” he notes. “The end result is more tailored lighting for tasks, improved patient comfort and energy savings.”

Systematic approach

In health care settings, optimizing the function of lighting systems is paramount, but it is important to recognize that these systems do not operate in a vacuum, adds Karyn Gayle, vice president of health care at Acuity Brands, Atlanta. “Lighting systems must comply with infection control guidelines throughout the facility,” Gayle explains. Also, manufacturers need to ensure that electromagnetic interference is avoided to ensure safe operation of medical equipment.

Clifford J. Yahnke, director, health care product management, Kenall Manufacturing, Kenosha, Wis., says manufacturers are focusing their attention on areas in which LEDs can be used to provide functional benefits in addition to energy savings. Two examples are:

• Improved visual acuity through better color rendition and/or the use of saturated colors. This is critical in environments such as the operating room in which the use of green light can eliminate glare and improve contrast when viewing monitors positioned throughout the room.

• The ability to create tunable spectrums that can emphasize particular colors at various times of the day for circadian entrainment.

The latest LED innovation is digital dimming and color control to create biodynamic lighting that replicates natural daylight throughout the day, experts agree. “This concept involves changing the color temperature of the lighting system from a very cool appearance in the morning to a much warmer color temperature in the evening,” according to Lou Calvo, director of sales and marketing, Waldmann Lighting Co., Wheeling, Ill. “This biodynamic approach provides the occupant with the color temperatures they would normally receive from daylight to maintain their circadian rhythm.”

Cree Inc., Durham, N.C., recently introduced adjustable correlated color temperatures for its CR Series LED troffers, enabled with Cree SmartCast Technology wireless lighting controls. “The system eliminates the need to decide on color temperature at the onset of installation, enabling the use of only one troffer in any space regardless of lighting preference,” says John Casadonte, vertical marketing manager, lighting.

You may also like |

| Lighting upgrades for energy savings |

| The role of color in health care lighting |

| Lighting controls help lower cost |

| |

Leviton, Melville, N.Y., has expanded its suite of daylight harvesting solutions with the launch of an Integrated Room Control (IRC) kit designed to deliver Title 24 2013- and ASHRAE 90.1 2010-compliant lighting control functions. The IRC combines daylight harvesting, 0- to 10-volt dimming, occupancy sensing and demand-response capabilities in an easy-to-install solution. A turnkey kit, the IRC is bundled with a sensor, photocell and entry station.

C3 Lighting Solutions Inc., Santa Ana, Calif., has developed an External Field Illumination System (EFIS) for operating rooms, which reportedly improves a surgeon’s vision by enhancing tissue detail. It uses large arrays of LEDs that can be varied in both the color and intensity of light output. This allows the surgeon to choose just the right amount and color of light to optimize his or her vision.

“Varying the color temperature of light output in five steps between 3,500 Kelvin (enhanced red) and 6,500 Kelvin (reduced red) improves a surgeon’s ability to differentiate between tissues of similar colors,” says Rick Farrell, president of C3 Lighting Solutions. “EFIS can be ordered with a GreenLite option for illumination during endoscopic procedures to reduce eye fatigue and reflections of LCD monitors.”

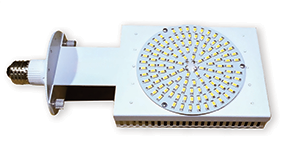

Revolution Lighting Technologies Inc., Stamford, Conn., has developed Dimmable LED Thin Panels that provide smooth, even light, which works well in dropped, T-bar grid ceilings. The panels are 0- to 10-volt dimmable, and can be integrated into lighting control systems to achieve ideal lighting and power consumption levels based on the schedules and needs of staff and patients.

While health facilities professionals understand the benefits of LED lighting, the main question is how to convert high-intensity discharge (HID) and fluorescent technologies to LED. Photonic Laboratories, North Arlington, N.J., is focusing on making the conversion simple and inexpensive.

Photonic Laboratories has introduced Ballast Direct, a technology that allows the conversion to LEDs without rewiring or replacing core components, including existing ballasts, within existing fixtures. “In the past, facilities managers were forced to replace entire fixtures, or rewire existing fixtures to retrofit LED lighting engines, in order to make the conversion,” CEO Alfred Heyer says. “With our system, you unscrew the old HID lamp and screw in the new LED lamp.”

Gaining efficiency

LED technology is becoming more energy-efficient, according to manufacturers. In fact, energy efficiency is being improved in both LEDs and accompanying optics. “Manufacturers are designing fixtures to accommodate the unique characteristics of LED by capturing and shaping the light in a more efficient fashion,” says Yahnke. “The result is not only energy efficiency within a single fixture, but also the opportunity to reduce the number of fixtures in a room.” A good example is an operating room in which it is now possible to reduce the number of lighting fixtures by 40 percent and save 27 percent on energy costs when moving from fluorescent to LED.

Where 80 to 100 lumens per watt was considered cutting edge just two years ago, a number of LED makers and fixture manufacturers recently have launched 140 lumens-per-watt capabilities. In fact, the average for LED lamps of all types is beginning to meet and exceed 90 to 100 lumens per watt, according to Treadway.

“Lighting also is increasing the lifetimes for maintaining output,” he notes. “Older HID and fluorescent technologies typically experienced depreciation of brightness over time, some in three to four years of daily use. Leading LED makers are now exceeding 100,000 hours of useful lighting output levels, which translates to 11 years at 24/7 use. Lifetimes are improving to 125,000 to 150,000 hours.”

New lighting systems also are being connected to building automation systems. “This is a major area of growth for lighting and automation control manufacturers,” says Calvo. “The ability to turn lights off in unoccupied areas, dim areas that receive little traffic or automatically close shades in areas exposed to sunlight — all contribute to significant reductions in energy consumption and maintenance.”

The growth of modular health care construction appears to be opening other opportunities. Denise Fong, IALD, LEED AP, principal with Candela, a Stantec Co., Lynnwood, Wash., has seen a prefabricated construction process in which most of the building is constructed off-site. When the prefabricated units are delivered to the site and connected, the lights already are installed and only the connections between units and building services need to be made.

“This could represent a new delivery method for fixture manufacturers that avoids the usual design/bid/build process and, instead, depends on building relationships between the fixture manufacturers and building manufacturers,” Fong says. Candela is Sparling’s lighting design and consulting division.

“Eaton continues to be asked for smaller and smaller LED products to accommodate the shrinking plenum space and, of course, we’re required to continue to increase energy efficiency,” adds Zawodny. “LED technology can aid in both of these. Its use in medical facilities will continue to increase, particularly as costs go down.”

Even organic LED (OLED) technology seems to have finally reached a tipping point in the marketplace, Gayle says. OLEDs are wafer-thin, diffuse light sources that are easily integrated into a vast array of design forms. “This exciting technology provides a useful complement to the increasingly ubiquitous LED, as good lighting design has always required directional, point-source illumination, as well as diffuse, area illumination,” she says.

Selection process

Facilities managers need to consider many factors when selecting and installing lighting systems. With any lighting product, whether fluorescent or LED, one needs to consider not only initial cost, but cost over the life of the system. “Some of the newer technologies still cost more than comparable fluorescent or HID products but present a significant cost savings with regard to energy and maintenance,” Zawodny says.

When it comes to solid-state lighting products, facilities managers should look for fixtures with Energy Star and Design Lights Consortium approvals. They offer basic assurance that the fixtures have been designed and tested in accordance with industry-recognized standards for performance and reliability, according to Scott Roos, vice president of product design, Juno Lighting Group by Schneider Electric, Des Plaines, Ill.

“When converting from conventional sources such as compact fluorescents and metal halide to LED, one should consider the photometric performance of the LED fixture and not just match the number of delivered lumens,” Roos explains. “Typically, LED fixtures with lower delivered lumens achieve better lighting than comparable conventional fixtures and have better lumen maintenance.”

Light the way

As LED continues to advance, it will open up new opportunities to address more lighting applications, introduce new form factors, integrate advanced functions and increase design flexibility, according to Casadonte. “Future gains in adoption may come from the realization that lighting is changing from a disposable commodity to a long-term asset, as the technology realizes improvements in efficiency, reduced cost and rapid payback,” he says.

Neal Lorenzi is a freelance health care writer based in Mundelein, Ill.

| Scene-settingWith both straight |

| Color moodThe CR22 LED Troffer with SmartCast Technology Lighting Controls features instantly adjustable color temperatures for color consistency while providing greater flexibility to control illumination. |

| Seeing clearlyThe Relucent External Field Illumination System for operating rooms uses large arrays of LEDs that can be varied in both the color and intensity of light output to allow the surgeon to choose the right amount and color of light for visual optimization. |

| Optimizing resourcesThe Metalux Encounter LED luminaire with integrated sensor control system is optimized for code-compliant occupancy detection and daylight harvesting, which reduces the design time and complexity of meeting energy codes for both lighting and controls. |

| In living colorLED ChromaControl luminaires are equipped with tunable white light, color tuning and black body dimming technologies. |

| Changing conditionsThe MedMaster M4 Series, now available with green LEDs, is specifically designed for surgical environments that call for a range of visual conditions and requirements. |

| Just rightThis integrated room control kitted system is a stand-alone daylight harvesting solution that delivers dimming and demand response capabilities. |

| Protecting an imageDesigned for medical imaging applications, FlatMAX MRI LED Flat Panels minimize any MRI interference and operate with a remote driver for installations where it is necessary to separate the electrical supply from the lighting fixture. |

| New visionBallast Direct allows users to upgrade expiring technologies to high-quality, high-efficiency LEDs without rewiring or replacing fixtures, ballasts or other critical components. |

| A little adjustmentDimmable LED Thin Panels provide smooth, even light, which works well in dropped, T-bar grid ceilings. |

| One for allThe Visiano LED exam light offers premium control and illumination in a slim design package for a physician practice, clinic or hospital setting. |