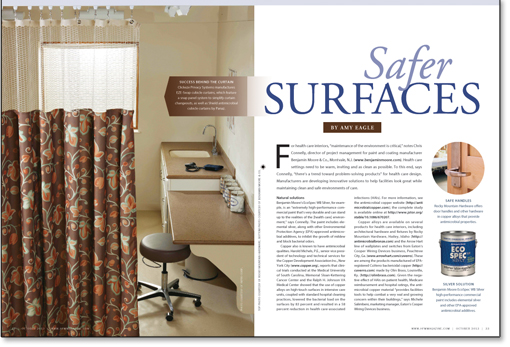

Click the above image for a PDF download

For health care interiors, "maintenance of the environment is critical," notes Chris Connelly, director of project management for paint and coating manufacturer Benjamin Moore & Co., Montvale, N.J. (www.benjaminmoore.com). Health care settings need to be warm, inviting and as clean as possible. To this end, says Connelly, "there's a trend toward problem-solving products" for health care design. Manufacturers are developing innovative solutions to help facilities look great while maintaining clean and safe environments of care.

Natural solutions

Benjamin Moore's EcoSpec WB Silver, for example, is an "extremely high-performance commercial paint that's very durable and can stand up to the realities of the [health care] environment," says Connelly. The paint includes elemental silver, along with other Environmental Protection Agency (EPA)-approved antimicrobial additives, to inhibit the growth of mildew and block bacterial odors.

Copper also is known to have antimicrobial qualities. Harold Michels, P.E., senior vice president of technology and technical services for the Copper Development Association Inc., New York City (www.copper.org), reports that clinical trials conducted at the Medical University of South Carolina, Memorial Sloan-Kettering Cancer Center and the Ralph H. Johnson VA Medical Center showed that the use of copper alloys on high-touch surfaces in intensive care units, coupled with standard hospital cleaning practices, lowered the bacterial load on the surfaces by 83 percent and resulted in a 58 percent reduction in health care-associated infections (HAIs). For more information, see the antimicrobial copper website (http://antimicrobialcopper.com); the complete study is available online at http://www.jstor.org/stable/10.1086/670207.

Copper alloys are available on several products for health care interiors, including architectural hardware and fixtures by Rocky Mountain Hardware, Hailey, Idaho (http://antimicrobialbronze.com) and the Arrow Hart line of wallplates and switches from Eaton's Cooper Wiring Devices business, Peachtree City, Ga. (www.arrowhart.com/cuverro). These are among the products manufactured of EPA-registered CuVerro bactericidal copper (http://cuverro.com) made by Olin Brass, Louisville, Ky. (http://olinbrass.com). Given the negative effect of HAIs on patient health, Medicare reimbursement and hospital ratings, the antimicrobial copper material "provides facilities tools to help combat a very real and growing concern within their buildings," says Michele Salimbeni, marketing manager, Eaton's Cooper Wiring Devices business.

Modular Services Co., Oklahoma City, Okla. (http://modularservices.com), has included a copper option in the company's Form collection of modular headwalls, footwalls and storage systems. "We wanted to offer a feature on our headwalls to further safeguard patients from HAIs," says Matt Palmer, marketing director. With the new WellJoint feature, the perimeter of each headwall panel is wrapped in copper to help prevent bacteria from growing in the hard-to-clean area between panels, which standard disinfection procedures may leave behind.

Another newly developed natural cleaning technology is PURETi, a spray that dries instantly to an invisible finish and gives indoor and outdoor surfaces self-cleaning, air-purifying properties. "It sounds too good to be true. We address that up front," says Glen Finkel, CEO and co-founder, PURETi, New York City (www.pureti.com). Made of water and 1 percent titanium dioxide, the product uses ultraviolet light and the natural humidity in the air to break down organic matter through the process of photocatalysis (the opposite of photosynthesis, in which light and water are used to create organic matter). PURETi's effectiveness has been studied by a number of independent universities and research organizations, including NASA's Stennis Space Center; the company has been designated a NASA dual-use technology partner for developing a product that meets both NASA and commercial needs, Finkel says.

Easy cleaning

Some products are designed for easy cleaning. The Rx Symphony line of ceiling panels manufactured by CertainTeed Ceilings, Valley Forge, Pa. (www.certainteed.com/ceilings), has good acoustic properties, a high light-reflection value and superior washability and stain resistance, according to Christine Fonock-Smith, product manager. The product resists water penetration and can be cleaned without the use of heavy chemicals. Even Betadine, which is known to be highly staining, is removed easily with low concentrations of mild detergent and water or water alone, says Darran Martin, CertainTeed coatings technologist.

Hospitals can trap dirt before it gets into the building with entrance flooring systems from Construction Specialties Inc. (C/S), Lebanon, N.J. (www.c-sgroup.com). "The less dirt you introduce, the easier it is to clean," says Curt Fessler, marketing director, LEED AP BD+C, C/S. This is a good value proposition, since it can cost $600 to remove a pound of dirt from a facility, he notes. The most recent addition to the C/S line of entryway systems is Floorometry,

a modular product manufactured in 18-by-18-inch tiles that install flush to the surrounding floor, for a high-end look that is easy to maintain. C/S Acrovyn wall and door protection also can help to maintain a sanitary hospital environment, as "it's very hard to clean a damaged surface," says Fessler.

Changing cubicle and privacy curtains can be difficult too. To make the job quick, easy and more likely to be done as often as needed, C/S offers the Snap Lock, Qwik Switch and Qwik Track curtain systems, all designed for fast removal and replacement.

Clickeze Privacy Systems, a division of InPro Corp., Muskego, Wis. (www.inprocorp.com), manufactures the EZE-Swap cubicle curtain snap panel system to simplify curtain change-outs, as well as Shield antimicrobial cubicle curtains by Panaz. "Shield technology lasts the life of the fabric and maintains its efficacy through normal use and laundering," says Thomas Larwa, senior product manager, InPro Corp.

The company's SureContact antimicrobial handrails are designed to prevent bacterial contamination of these frequently touched surfaces. Its Palladium wall panels and BioPrism solid surface material are both designed to be durable, resistant to mold and mildew growth, and easy to clean.

Material design

Corian solid surface, manufactured by DuPont, Wilmington, Del. (www.surfaces.dupont.com), is nonporous, easily cleaned and meets all 18 guidelines for finishes and surfaces outlined in the Facility Guideline Institute's Guidelines for Design and Construction of Health Care Facilities, says Susan Homan, commercial marketing director, DuPont Building Innovations.

For areas like operating rooms, Corian vertical cladding material provides a number of design options, such as the ability to add curved surfaces and color, that are not available with traditional clinical materials like stainless steel. Seamless fabrication techniques allow components like sinks and flat-screen monitors to be integrated smoothly into the material.

These qualities are evident in Patient Room 2020, a prototype "patient room of the future" developed at the DuPont Corian Design Studio in New York City in partnership with nonprofit research and design firm NXT Health, New York City (http://nxthealth.org). In a feature called the Patient Ribbon, a wide, streamlined band of Corian curves over the bed from the headwall to the footwall, seamlessly integrating elements like medical gas outlets, programmable lighting, a patient lift and flat-screen monitor.

"Infection control is a major concern of health care providers," says Homan. Easily cleaned materials that can be formed and designed to meet the needs of the health care environment can help to reduce infections.

"If we can do that through a product offering, that's one less thing [providers] have to worry about," says Larwa of InPro Corp.