Clearing the air

Managing exhaust air quality is critical for all hospitals. Among the issues that must be confronted are eliminating re-entrainment of emergency diesel generator exhaust; exhausting sensitive research laboratory workstations; managing isolation room exhaust; and other HVAC issues as well such as heat recovery for energy savings.

While there are many methods to accomplish these objectives, over the past few decades the use of mixed flow impeller technology has become a proven solution for many hospital applications. This technology incorporates low-profile roof fan exhaust systems that operate on a unique principle of diluting exhaust air -- regardless of its source -- with unconditioned, outside ambient air.

The result is a virtually odor- and pollution-free exhaust stream with exit velocities as high as 6,300 feet per minute (fpm) and a jet plume up to 120-feet high. The jet plume exhaust disperses and dilutes pollutants high enough into the atmosphere to meet pollution abatement laws, while eliminating odor and preventing re-entrainment into the building or adjacent buildings. Such systems also can incorporate bag in/bag out HEPA filtration.

Success in the field

The following examples show how this technology solved exhaust issues at three different hospitals:

1. Exhausting sensitive research laboratory workstations in an urban environment. Research laboratories in urban areas face special problems with regard to safely exhausting sensitive laboratory workstations, particularly biosafety level (BSL) labs. This was the case at the Albert Einstein College of Medicine of Yeshiva University in New York City, a 4-million-square-foot facility where 300 laboratory workstations are employed for a variety of cutting edge applications. In addition to the obvious indoor air quality (IAQ) issues to be managed in this environment, major concerns focus on efficiently and safely exhausting the fume hoods at its laboratory workstations to the atmosphere.

New facility construction has been a key factor for Einstein's growth cycle. To that end, when the college originally built its Samuel H. and Rachel Golding Building, Peter Pessoni, assistant director of operations and maintenance, learned about an energy-efficient method of laboratory workstation exhaust that would help meet the institution's requirements of healthy IAQ as well as safe, legal atmospheric exhausting.

Pessoni says that in 1995, the Golding Building's mechanical systems were designed by a mechanical-electrical-plumbing engineering firm that suggested use of mixed flow impeller laboratory exhaust systems to replace more traditional, individually dedicated mushroom-type fans on the roof. Pessoni adds, "The advantages include safe, effective workstation fume-hood exhaust which is mixed with outside, ambient air at the roofline and sent in a powerful vertical plume hundreds of feet above the roofline to comply with appropriate environmental codes as well as to prevent objectionable odors in the neighborhood."

|

|---|

| The 300 laboratory workstations at the Albert Einstein College of Medicine in New York City use advanced design mixed flow technology roof exhaust systems for safely exhausting fume hoods. |

2. Eliminating re-entrainment of emergency diesel generator exhaust at a medical center. Hospitals' compliance to maintain -- and routinely test -- independent power generation systems posed a serious problem at the Valley Medical Center in Renton, Wash. Diesel fumes, emitted during the testing procedures, were being re-entrained into the hospital's fresh air supply ventilation system.

Options to solve this problem were to either extend the generator's exhaust stack, which terminates one floor below the penthouses on the third-floor rooftop, or move the emergency generator outside the building. The design of the stack didn't warrant extending it more than 20 feet, and moving the generator would be costly. A third option came from a mechanical contractor that specializes in HVAC equipment and a Seattle distributor of air handling equipment, which suggested a simple solution through the use of a mixed flow technology roof exhaust system that operates on the principle of mixing outside air with plenum air at a high-velocity discharge (up to 6,600 fpm) to eliminate these kinds of problems.

The system operates on a unique principle to enhance exhaust volume by as much as 260 percent of design flow by mixing outside air with exhaust fumes at the exit of the fan nozzle.

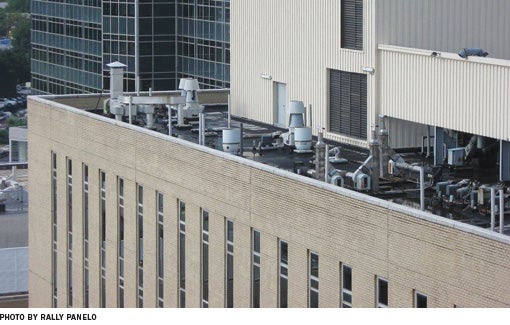

|

|---|

| The mixed flow impeller exhaust system on the roof at Valley Medical Center prevents re-entrainment of emergency diesel generator exhaust into the hospital's fresh air supply ventilation system. |

3. Managing hospital isolation room exhaust at a LEED transplant center. Researchers at a new organ transplant center, part of a major university health care system in the Midwest, are keenly aware of health and safety implications associated with exhausting sensitive areas.

At this LEED-qualified facility one of their major considerations involved safely exhausting two critical isolation rooms dedicated to transplant patient recovery. Because room exhaust re-entrainment was not an option, facility managers requested studies to determine the affects of prevailing winds on the hospital and surrounding buildings. In addition to preventing re-entrainment, owners and architects were concerned with not having tall, unsightly exhaust stacks protruding above the roofline, which commonly are perceived as neighborhood pollution sources. These factors -- along with eliminating possible odiferous exhaust -- led to management's decision to use mixed-flow impeller roof exhaust systems.

Roof exhaust re-entrainment at medical facilities with isolation rooms -- as well as those with sensitive teaching or research laboratories -- can be insidious and often dangerous. This is especially true at Biosafety Level 3 and 4 laboratories, where highly contagious microorganisms may be present. Consequently, these laboratories must incorporate many special design and engineering features to prevent microorganisms from being discharged into the environment. Just like hospital isolation rooms, these design features could include specially shielded rooms under negative pressure with sophisticated airflow, temperature, pressure, humidity control and monitoring systems; they typically incorporate 100 percent conditioned makeup air to prevent recirculation of the ambient air within an enclosed facility. In this case, the hospital complex incorporated all of these features for its new isolation room ventilation.

Cost-effective approach

Mixed flow exhaust technology offers a practical, cost-effective approach for solving a variety of air pollution problems as well as complying with appropriate environmental codes and standards. Its high-volume jet plume disperses pollutants high enough into the atmosphere for legal compliances along with eliminating perceptible odors. Powerful vertical plumes and effective exhaust stream dilution--prevent re-entrainment of harmful or unwanted fumes into a building's intake air ventilation systems, doors, and windows, as well as into adjacent facilities.

Paul Tetley is general manager at Strobic Air Corp., Harleysville, Pa. He can be reached at ptetley@strobicair.com.