Planning for efficiency

On average, nurses travel more than five miles during one shift and much of it is inefficient motion. Regardless of caregivers' proficiency, systemic inefficiencies such as this are a major contributor to medical errors.

On average, nurses travel more than five miles during one shift and much of it is inefficient motion. Regardless of caregivers' proficiency, systemic inefficiencies such as this are a major contributor to medical errors.

Many of the inefficiencies found within a health care facility can be easily remedied by adapting the same Lean methodologies implemented by manufacturers on the production line.

By identifying and resolving struggles, health care providers can create spaces that support simplified work processes and ultimately shift the focus to the patients.

What is lean?

Coined in the 1990s, "Lean" was used to describe the Toyota production system. The primary idea behind Lean is simply to create more value for the customer by reducing waste.

By adopting Lean thinking, organizations such as health care facilities, create processes that provide more customer value with less effort, capital or space. This streamlined approach not only lowers production costs and errors, but also positions organizations to more quickly respond to evolving customer needs.

|

| Versatile, modular furnishings within the patient room should embrace the power of space to create a welcoming environment for patients and families. |

Within the manufacturing sector, there are two popular Lean approaches:

Toyota production system. This management philosophy focuses on minimizing the seven forms of waste — including overproduction, waiting, conveyance, process, inventory, motion and correction — to improve overall customer value. Many of these forms of wasteful manufacturing pitfalls are also evident in the hallways of health care facilities today. For example:

- Conveyance inefficiencies can be found with movement of equipment, patients or medical supplies. Moving a patient is not the same as delivering care.

- Inventory inefficiencies can occur when there are either too many medical supplies on hand or when these supplies are in the wrong locations and do not get used.

- Motion, a common form of health care inefficiency, occurs when caregivers have to search for medical supplies or data, or when there is unnecessary reaching, bending and twisting for supplies or patient access.

- Correction inefficiencies refer to the time lost from resolving an error, such as searching for patient belongings, administering wrong or missing drugs, or reviewing supplies and data

The Toyota production system is built on two pillars: Just-in-time (JIT), a production strategy that essentially produces and conveys only what is needed when and in the amount that it is needed to meet the exact demand of the customer; and Jidoka, or "autonomation" (automation with a human touch), which allows work to be stopped in the event of a problem, such as equipment malfunctions or quality problems.

With a focus on continuous improvement, JIT and Jidoka can advance an organization's overall efficiency and end-product quality to ensure a greater return on investment for its consumers. In fact, the combined power of those two pillars built on a stable foundation has helped Toyota become one of the largest automakers in the world.

There have been many interpretations of the Toyota production system. However, not all are in sync with the original. Caution is suggested in evaluating consulting services. It is also important to note continuous improvement is just that: continuous. Thus, the Toyota production system is not an overnight event, but rather a prolific journey.

Six Sigma. Originally conceived by Motorola in 1986 and widely adopted by General Electric in 1995, Six Sigma uses a set of quality management tools, including statistical methods and a special internal infrastructure to remove the cause of errors, minimize manufacturing variability and, ultimately, improve quality of output. Because of the need for significant mathematical analysis, Six Sigma experts or "black belts" are often required to diagnose and implement improvement efforts.

Health care applications

So how do these continuous improvement approaches apply to health care? In today's competitive landscape, cutting through the complexity of a facility with flexible solutions is just as critical to improving patient satisfaction and safety as it is to improving the bottom line. By applying a Lean state of mind from internal processes to design, health care facilities are able to identify features that add value and cost-effectively create a space that works harder for those visiting, working and healing there.

Streamlining workflow. Pittsburgh Regional Health Initiative (PRHI) was one of the nation's first regional collaboratives of medical, business and civic leaders organized to address health care safety and quality improvements. In an effort to help facilities eliminate errors, decrease inefficiencies, and deliver better patient care, PRHI looked to lean as its solution. In a joint venture with VA Pittsburg health care System's acute care hospital and the Centers for Disease Control and Prevention, PRHI used its methodology based on Lean concepts and the Toyota production system to improve methicillin-resistant staphylococcus aureus (MRSA) control strategies.

|

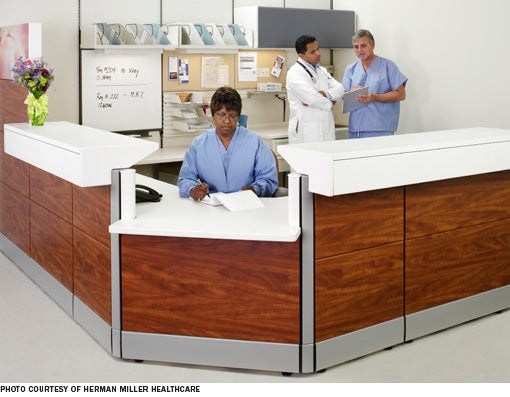

| Flexible work stations, such as this nurses' station reception counter, must respond to the changing needs of facility and staff. |

Through protocols such as improving access to equipment and materials staff needed for MRSA patients, creating a reliable supply of gowns, gloves and hand hygiene supplies, the team was able to free up time for staff to devote to infection control. These protocols helped the VA record an 85 percent reduction in MRSA for post-operative patients. Because of that success, the protocols were adopted within 176 VA facilities across the country.

Through Lean education and a team-based effort to mitigate complexity, facilities can eliminate obstacles like the VA did to create a seamless workflow for caregivers and a better, safer experience for patients.

Waste-free design. Often, waste is not just generated by the layout of work processes but by the layout of a hospital itself. In this instance, the best lean approach typically depends on where the hospital is in the design process.

In the planning stages prior to facility construction, a 3P (production, preparation, process) approach ensures lean is the foundation for the layout overall. 3P emphasizes improving processes already in place by focusing on eliminating waste through product or process design. It combines a clean slate and a diverse group of individuals to rapidly brainstorm and test creative solutions to solve the challenge at hand. The result is shifting a seemingly impossible internal challenge into a tangible, workable solution in a relatively short amount of time.

Design consultants Joan Wellman & Associates Inc., Mercer Island, Wash., used 3P when planning a $300-million campus expansion within a multi-hospital system. Their goal was to provide flexibility for the space to fit up to 100 beds while focusing on patient satisfaction. By analyzing opportunities for improvement, the team was able to find new ways to use existing, occupied space, reducing new construction by over 6,000 square feet and saving the organization $2.3 million in costs.

When a facility is already established, lean design, which largely focuses on the Toyota production system's aforementioned seven forms of waste, allows facilities to integrate flexibility where it may not have existed previously through reconfigurations, spatial considerations and furnishings.

West Chester Hospital in Cincinnati had the goal of creating an exceptional health care experience for patients through Lean design. Yet, while being Lean means being flexible enough to keep pace with evolving changes, the hospital team noticed their current lab was just the opposite: casework had been built in where a modular system had been requested.

With limited flexibility, the staff was unable to properly outfit two large chemistry analyzers within the space — analyzers that would ultimately fuel their patient-focused mission. To remedy this situation, the built-in system was replaced with modular lab furniture that allowed the room to adapt to the processes instead of the processes adapting to the room.

To truly enhance the patient experience, the hospital also put focus on the patient room itself with comfortable, flexible furnishings that require minimal footprint, from modular storage systems to patient and family seating. Embracing the power of space, the hospital eliminated the industrial feel of a typical hospital by creating a warm, welcoming healing space for patients and their families while also providing caregivers with greater mobility and patient access.

Top tenets

To achieve an exceptional health care experience through lean design, it is essential to follow these tenets:

Continuous change. In order to keep pace with evolving patient needs, furnishings and health care design layouts should continuously be evaluated to ensure they are doing just that. Instilling adaptive flexibility throughout the design of a health care space will allow it to be changed quickly and easily should a layout become obsolete as the result of new technology or changing objectives.

|

| Lab systems should offer flexibility to meet continually changing work space needs. |

Surrender the space. It's easy to design idiosyncratic alcoves and miscellaneous areas of a facility that have a single use. However, with a lean state of mind, these spaces must be re-imagined to accommodate other functions when other needs arise such as respite areas or work stations, responding to the changing needs of the facility, staff and patients.

Modular. By implementing modular furnishings and layouts, which are constructed with standardized units or dimensions that can be interchanged, health care designers ensure solutions that are reconfigurable and offer a variety of use.

'Less is more'

Health care facility waste can hinder the experience of all stakeholders involved: patients, families and caregivers. By applying Lean at every level of care, health care spaces will be better equipped to adapt to evolving stakeholder needs, streamline processes and, ultimately, create a more comfortable healing environment overall.

This "less is more" approach not only eases the emotional and physical stress often experienced by staff, but allows greater quality and value for the patient to ensure better outcomes.

Roger Call is a registered architect and director of health care architecture and design for Herman Miller Healthcare, Zeeland, Mich. He can be reached at roger_call@hermanmiller.com.