HVAC systems for off-site care

As hospitals build more small, off-site facilities, health facilities professionals are turning to packaged and split HVAC systems to meet the needs of these smaller facilities, and manufacturers are developing a wide array of options.

Packaged and split HVAC systems usually are defined as direct expansion (DX) systems, in which air is cooled directly from the evaporation of a refrigerant, as opposed to using an intermediate medium like chilled water. A packaged system has both the evaporator and condenser sections in the same housing, while a split system separates the two, with the evaporator usually inside the structure and the condensing section outside, according to Clay Seckman, PE, senior principal, Smith Seckman Reid Inc., Nashville, Tenn.

The benefits of such systems include low initial cost, ease of operation, remote monitoring and minimal use of space inside a building. Limitations include low energy-efficiency, limited longevity and limited humidity control capabilities without special features. “Quality and reliability can be limited, depending on the vendor and application,” Seckman says. “Systems sometimes cannot handle differing load patterns or simultaneous heating and cooling needs.”

Packaged systems include many conventional systems that have been used in the United States. “Split HVAC systems or ‘mini-splits’ are more common in Europe and Asia, but are now gaining a foothold here,” says Brendan Casey, commercial product manager, Fujitsu General America Inc., Fairfield, N.J. “The biggest difference is that mini-split systems almost always include variable-speed, inverter-driven compressors, which improves efficiency and reliability.

“The growth of mini-splits in North America was first driven by owners who were looking to provide additional cooling or heating to a specific room,” Casey continues. “Today, we see many buildings that are equipped with 100 percent mini-splits from the initial design phase. Because these systems are quiet and efficient, they are very popular with health care facilities.” Mini-split systems generally are meant for smaller buildings or buildings with rooms that require individual, localized control.

New environments

As hospitals build more off-site physicians' offices, urgent care centers and other stand-alone facilities, the demand for packaged and split HVAC systems has increased, according to manufacturers that supply the nation’s hospitals. While outpatient and medical office facilities have been using these types of systems for years, “there appears to be more consideration for packaged units and split systems because the new technologies have made them capable of handling rigorous health care requirements,” says Richard D. Hermans, PE, director of training and advanced applications, Daikin Applied, Minneapolis.

Daikin Applied manufactures complete packages of heating, ventilating, air conditioning and control systems that provide all code-required environmental conditions in health care settings. “To be truly useful to health care engineering professionals, these units are flexible and configurable to produce the customized air quality needed in off-site clinics,” Hermans says. “Since they are more or less complete and are placed on the roof, they allow the building to be designed with smaller mechanical rooms or no mechanical rooms at all.”

With the improvements in DX system technology, packaged and split HVAC systems can meet the temperature and humidity control needs of most health care facilities, without the costs associated with large hydronic systems, according to Eric Taylor, marketing manager, AAON, Tulsa, Okla. “Lower first costs along with precision control and flexibility make DX systems ideal for small health care facilities. The technology, which was introduced by semicustom HVAC system manufacturers such as AAON, has the same type of double-wall construction available on custom equipment and many of the same features,” he notes.

This type of equipment provides the greatest benefit for spaces that have multiple zones and varying occupancy, which include off-site health care facilities. “We see most demand coming from satellite patient care facilities, such as physician offices and skilled nursing facilities designed for long-term rehabilitation. The flexibility of packaged and split-system equipment allows it to be customized to many of these health care applications,” Taylor says.

The major benefits of this technology include energy-efficiency, application flexibility, low installation cost and time savings, experts agree. “The primary benefit to using these systems is cost. The right packaged units can now be applied in health care because of their increased capabilities and flexibility. There are still limitations, but only in some specialized health care spaces such as isolation and surgery,” says Hermans.

Existing challenges

Despite improvements in the efficiency of these systems, manufacturers and users face challenges. However, the challenge of operating and maintaining these systems is different from those posed by large centralized HVAC configurations.

“They tend to require more attention and periodic inspection to ensure that they are performing according to health care standards. Also, the design community is slow to accept applying these systems even though they are fully capable of complying with health care standards,” Hermans says.

The greatest challenge is educating building owners and end users about the benefits of these systems, according to Casey. “Even though today’s systems can provide heating in outside temperatures down to -15 degrees Fahrenheit (F), some people are still concerned about using a heat pump for year-round heating,” he notes.

A major challenge that off-site health care facilities deal with is supplying ventilated outside air to the inside space. Controlling outside air can be difficult because of wide fluctuations in temperature and humidity. In response, AAON packaged and split-system equipment incorporates such features as modulating cooling, energy recovery, high-efficiency filtration, modulating dehumidification and modulating heating that allow conditioning of fresh outside air to promote patient healing.

“When supplying fresh outside air, the equipment must handle a wide range of air conditions from hot and humid to cold and dry,” says Taylor. “Each air condition presents a specific challenge to the equipment. The latest equipment is engineered to overcome these challenges.”

In the past, these features were available only on customized DX rooftop equipment that carried a high price tag, says Stephen Clinton, PE, LEED AP, sales engineer with manufacturers’ representative firm REA Inc., Nashville. “Some current DX air-handling systems can provide up to 240 tons of cooling capacity and system performance that matches traditional chilled water, air-handling systems. Our customers have used these DX systems in packaged and split-system configurations to serve a wide array of health care, laboratory, clean room and other critical environmental projects,” he notes.

Product variations

Among the variations in smaller HVAC products, a duct-free split air conditioning system consists of an indoor unit (evaporator) and an outdoor unit (condenser), connected by refrigerant lines, according to Kevin McNamara, vice president of air conditioning, LG Electronics, Englewood Cliffs, N.J.

“A packaged system can be bulky, which may limit installation options. It can be more expensive than a duct-free split system because a professional contractor has to design the layout of the ductwork. The installation of packaged units also requires additional work and accessories,” he says.

A duct-free split system, on the other hand, is lightweight, compact and offers energy savings, McNamara says. It can be installed without disruption to a facility or its occupants. Duct-free split systems often are used in small facilities because of their installation flexibility, zone control and energy savings. With a duct-free split system, indoor units can be installed anywhere from a single area, like a nursing station, to individual exam rooms.

“Duct-free split systems allow users to place individual controls throughout the facility, so they have the opportunity to independently adjust the temperature in different areas as needed. LG’s light commercial Multi F MAX duct-free split air conditioners let users individually control up to eight different rooms or zones, depending on the size and style of the system,” McNamara adds.

LG indoor units also are aesthetically appealing, because all models are designed with style and functionality in mind. The LG Art Cool Gallery duct-free system is one example. The indoor unit has a 20-by-20-inch glass panel frame that allows users to insert and display artwork or photography in doctors’ offices, medical clinics, outpatient facilities, nursing homes and assisted living facilities.

The Mitsubishi Electric U.S. cooling and heating division, Suwanee, Ga., manufactures variable refrigerant flow (VRF) zoning, a technology that cools or heats each room or zone in a building to the level needed, maximizing comfort and energy-efficiency. Applications include both new construction and renovations in off-site health care and mixed-use facilities.

Mitsubishi Electric introduced VRF zoning technology to the U.S. market 11 years ago, according to Kevin Miskewicz, senior manager, commercial marketing. The systems connect one outdoor unit to as many as 50 indoor units through small piping and electrical wiring.

“VRF zoning technology is just a smarter way to cool and heat buildings,” says Miskewicz. “Traditional heating and cooling systems require tremendous energy to force air from a central blower to a room through a complex system of ductwork, which uses building space and wastes energy. With VRF zoning systems, installation time is reduced, building occupants are comfortable and energy bills are lower.” Another benefit is the lack of noise produced by indoor and outdoor VRF units.

Carrier Corp., Charlotte, N.C., offers WeatherExpert single-package rooftop units, available in 75- to 150-ton capacities. Suitable for small, off-site health care facilities, they offer low installation, maintenance and energy costs, according to Carrier. Featuring a double-wall foam panel cabinet design, the units are available in dedicated vertical, horizontal and mixed supply/return airflow configurations for constant volume, staged air volume or variable air volume applications. Each model comes with a direct digital control system.

“The WeatherExpert units deliver optimal comfort and energy savings at both full- and part-load conditions,” says Greg Alcorn, vice president, independent distribution. “Control logic operates the multistage system to provide efficient operation with comfort control.”

Fujitsu General America Inc. recently introduced ductless split systems that offer a 33 seasonal energy-efficiency ratio rating with low-temperature heating. The inverter wall-mount systems are available as split-system heat pumps and offer quiet operation and nearly full heating capacity down to -15 F ambient and cooling operation down to 14 F. Refrigerant pipe lengths can reach 66 feet between the evaporator coil and the condensing unit.

The systems use room motion sensors to conserve energy. The motion sensors note when the room has been vacated. After 20 minutes, the set temperature is increased by 4 F when in cooling mode, and reduced by 8 F when heating. When the room is reoccupied, external static pressure returns to the previous operating mode.

Changing demands

The application of these systems will depend on the degree to which outpatient and ambulatory facilities continue to take on more and more acute-level functions and modalities, according to Seckman.

“As more procedures and services move to the outpatient setting, the ability of traditional packaged and split-system equipment to meet these needs may become challenged,” he says. “Manufacturers will have to respond and adapt to these changing demands for improved indoor air quality, temperature and humidity control, and reliable service — all while meeting first-cost and operating-cost expectations.”

Neal Lorenzi is a freelance health care writer based in Mundelein, Ill.

| Critical capacitiesWeatherExpert rooftop HVAC units are available in 75- to 150-ton capacities for physician office buildings, surgery centers, elder care facilities, laboratories and other applications. |

| Let it flowThe Hyper-Heating Inverter R2-Series variable-refrigerant flow cooling and heating system is suitable for buildings in climates that require varied heating and cooling points, including a wide variety of health care facilities. |

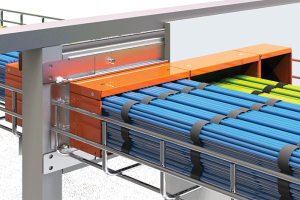

| Multiple levels This double-wall RoofPak applied packaged rooftop system can be adapted to many levels of care, such as hospitals, clinics, urgent care centers and more. |

| Variable demandThe CF Series split-system condensing units are available with variable-capacity scroll compressors for fully modulating cooling capacity. |

| Energy-efficientDuctless split systems offer a 33 seasonal energy-efficiency ratio rating with low-temperature heating. |

| Artistically speakingThe Art Cool Gallery inverter air conditioner allows users to personalize the frame of the air conditioner (left) and is now compatible with the Multi F MAX outdoor unit (right) to support up to eight indoor units. |