New California hospital utilizes wall technology to withstand earthquakes

|

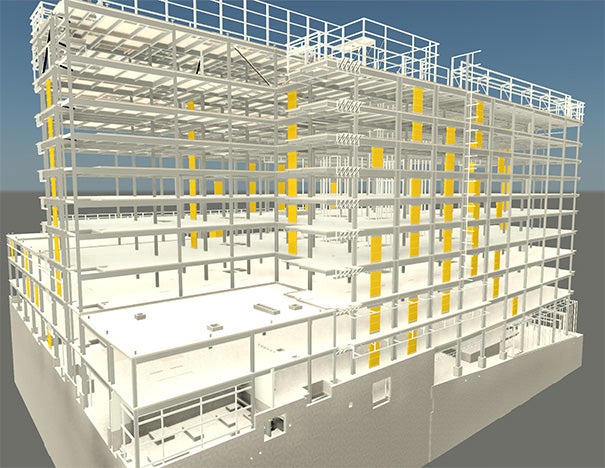

| Rendering Courtesy of Sutter Health The 740,000 sq. ft. hospital is using a technology that not only will help it meet California seismic codes but also reduces the amount of structural steel needed in the building. |

Sutter Health’s new $2 billion California Pacific Medical Center Van Ness and Geary Campus in San Francisco is utilizing a building technology that will help the hospital to meet the state seismic code, provide design flexibility and help to reduce the cost of the project.

Construction of the 12-story hospital with 740,000 sq. ft. of clinical space and 274 beds will include installation of 120 viscous wall dampers (VWD) that will reduce any lateral movement caused by earthquakes and wind by absorbing energy.

|

| Photo courtesy of DIS Construction workers receive the first DIS viscous wall damper delivered to the hospital site. |

The technology reduces stresses in the structure itself by more than 50 percent and will eliminate enough structural steel to pay for itself, according to Kevin Friskel, senior engineer, Dynamic Isolation Systems (DIS), McCarran, Nev.

VWD technology was originally developed in Japan. DIS introduced the technology to the U.S. market and obtained approval from the Office of Statewide Health Planning and Development for use in hospitals in California.

The use of VWD raises the new hospital to performance based-design, which means that if an earthquake strikes, the facility will be usable and capable of being occupied, Friskel says.

A facility built to meet the minimum requirement of life-safety design can sustain extensive damage but not collapse, he explains. The building cannot, however, be occupied after an earthquake.

Installing the VWD provided the design upgrade at no cost because the wall technology eliminated some of the structural steel that would have been needed otherwise, Friskel says.

|

| Rendering courtesy of Sutter Health The new hospital is adopting sustainable features, such as a 100 percent filtered, outside air system. |

Each VWD consists of a narrow steel tank connected to the lower floor, an inner steel plate connected to the upper floor and a viscous fluid in the small gap between them. During a seismic event, the floor movement causes the vane to move through the viscous fluid, according to DIS.

The damping force from the shearing action of the fluid depends on the displacement and velocity of the relative motion. Wall dampers are used to reduce the seismic accelerations and inter-story drifts by more than 50 percent, the company explains.

The viscous fluid used for all dampers is a nontoxic, odorless transparent fluid with a viscosity of 90,000 poise. The wall can be made to fit typical openings in a building.

In addition to use of the innovative wall technology, the new hospital is making sustainability an important element of the design. It will incorporate a 100 percent filtered, outside air system, highly diverse vegetated exteriors and water-conservation strategies.

The project, which includes construction of an adjacent nine-story medical office building, is scheduled to be completed the first quarter of 2019.

Click to watch a video on VWD technology made by DIS.