Memorial Hermann earns energy-saving honors

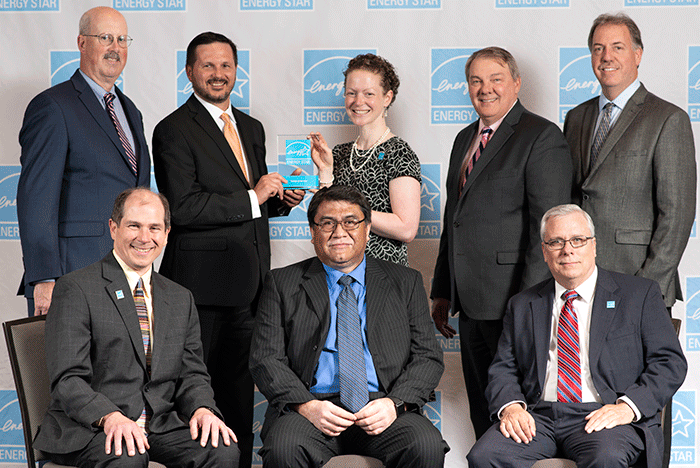

Memorial Hermann team members accepting the 2018 ENERGY STAR Partner of the Year — Sustained Excellence Award include (top row, from left) Michael Hatton, vice president of system engineering; Todd Harvey, director of engineering (Memorial Hermann Cypress Hospital); Carolyn Snyder, director of Environmental Protection Agency's (EPA’s) Climate Protection Partnerships Division; Terry Scott, regional director of engineering (Memorial Hermann Southwest Hospital and Memorial Hermann Greater Heights Hospital); Patrick Shay, director of engineering (Memorial Hermann The Woodlands Medical Center); (bottom row, from left) Clark Reed, ENERGY STAR, EPA; Juan Hurtado, engineering manager (Memorial Hermann Katy Hospital); and Larry Newlands, energy manager, Memorial Hermann.

Memorial Hermann Health System, one of the largest not-for-profit health systems in southeast Texas, is earning impressive accolades through its efforts to cut energy use.

Ten of the organization’s 14 hospitals earned ENERGY STAR certification from the EPA in 2018, including its two newest Houston-area hospitals in Pearland and Cypress, which opened in the last two years.

The fact that the latter two facilities earned the ENERGY STAR label only 13 months after first occupancy and one month after being eligible speaks to the success of Memorial Hermann’s ambitious energy efficiency efforts.

(Memorial Hermann Health System owns and operates 14 hospitals and has joint ventures with five other hospital facilities.)

Reaping the rewards

Consider that, among over 5,500 hospitals in the United States, only 56 (1 percent) are currently ENERGY STAR-certified; 10 of those hospitals are under the Memorial Hermann banner.

According to ENERGY STAR, energy use intensity (EUI) ranges from less than 100 to more than 1,400 kBtu per square foot across all hospitals. Pearland, Cypress, and two other Memorial Hermann hospitals can boast site EUI in the 120 to 140 range, compared to a 300 to 400 EUI rating achieved by many new hospitals. What’s more, Pearland and Cypress achieved ENERGY STAR ratings of 93 and 98, respectively; the average ENERGY STAR rating among other participating hospitals is only 50 (to be ENERGY STAR certified, a rating of 75 or higher is required; seven Memorial Hermann hospitals are rated 90 or higher).

As a result, Cypress, Pearland and two other high performing hospitals consume only $2.30 per square foot in natural gas, water, and electricity annually versus $4 per square foot spent by other Memorial Hermann legacy campus locations – equating to a 40 percent improvement in utility costs.

Memorial Hermann began its energy conservation initiative in 2008, when it first started building new facilities and recommissioning existing ones according to best practices in the field and ENERGY STAR guidance. Since then, the organization has validated savings of over $100 million in heating, cooling, water and other utility costs. Additionally, facility operating expenses for controllable maintenance budgets (utility category) have been reduced to approximately 30 percent, down from 50 percent.

Planning pays off

Michael Hatton, MBA, FASHE, Memorial Hermann’s vice president of facilities engineering and immediate past president of the Texas Association of Health Care Facility Managers, attributes these collective savings to a variety of factors and practices. These include goal-setting, targeting ENERGY STAR as a key owner’s project requirement (OPR), day one facility benchmarking, and closely working with ASHE’s Energy to Care program.

“Hospitals can greatly improve their bottom line for minimal expenditures by following the guidelines of the Energy to Care program,” he says. “Doing so can also help you achieve ENERGY STAR certification and benefit the environment.”

Memorial Hermann has followed four themes as guiding principles in designing, constructing and operating its facilities, according to Hatton:

- Move less water.

- Move less air.

- Vary the temperature of water and air to match seasonal requirements of the space.

- Benchmark and publish outcomes monthly as quality improvement and to promote internal competition.

Hatton notes that Memorial Hermann didn’t necessarily rely on costly state-of-the-art technology to reach its energy savings goals. Instead, its teams turned to best practices like design and peer reviews, life cycle evaluations, improved preventive maintenance, and focused commissioning along with cost-effective and highly reliable technology, equipment and optimized building controls.

Key features of a Memorial Hermann hospital with a 90-plus ENERGY STAR rating include:

- Energy-efficient LED lighting vs. traditional fluorescent T-8 lighting.

- Variable primary chilled water distribution, which is easier to keep in balance, especially when sequencing chillers to various building load demands.

- Condensing re-heat boilers and 100 degrees F reheat distribution.

- Minimum/maximum room ventilation schedules based upon local Department of Health and ASHRAE 170 air flow requirements for health care.

- Adoption (and follow-up) to ensure every zone and air terminal box is balanced to achieve ASHRAE 170 minimum/maximum requirements.

- Key seasonal building control resets for air handler discharge air temperature and static pressure, chilled, condenser and reheat water temperature – all of which vary by building load and/or seasonality.

- Dedicated outside air pre-treatment air handler units.

- Point-of-use steam generation, which avoids the thermal losses of central steam distribution.

- An empowered facilities engineering/operations staff who are allowed to take measured risks and provide crucial project input.

Hatton is particularly proud of the fact that Pearland and Cypress achieved their high level of energy performance on opening day.

“Previous Memorial Hermann hospitals took years of tuning and retro-commissioning to achieve similar levels of utility cost savings. This journey toward energy efficiency and cost reduction was achieved with much effort over a period of 10 years,” says Hatton, adding that Memorial Hermann also recently received a 2018 ENERGY STAR Partner of the Year Sustained Excellence Award for continued leadership and superior contributions to ENERGY STAR — the fifth time the organization has been recognized with this accolade.

Memorial Hermann was also careful to avoid negatively affecting the patient experience or health outcomes over the past decade.

“Our enhanced focus on energy efficiency likely improved patient care because it forced our facilities to pay closer attention to temperature, humidity and air flow deviations in order to ensure more reliable HVAC systems in support of patient care.” Hatton says.

ASHE aims to help

Kara Brooks, MS, LEED AP BD+C, sustainability program manager for ASHE and Energy to Care supervisor, says the program was instrumental in helping Memorial Hermann earn these accomplishments.

“These are incredible achievements that demonstrate how truly hard Memorial Hermann has worked,” says Brooks, noting that Memorial Hermann has also won five Energy to Care awards in 2018 – bestowed for saving 10 percent on energy costs within a year’s time. “The Energy to Care program helped their health system achieve its energy efficiency goals through recognition and educational resources, which also provided opportunities for them to learn and improve.”

Health care organizations spend more than $6.5 billion on energy each year, reports ENERGY STAR; every $1 a non-profit health care organization saves on energy is equivalent to generating $20 in new revenues for hospitals or $10 for medical offices.

By achieving greater energy savings, Memorial Hermann and other hospitals “can free up resources to support the organization’s mission of providing patients with the best care. We encourage organizations to allocate these utility cost savings back into patient care,” adds Brooks. “And that’s where Energy to Care is so valuable. The program provides an energy benchmarking tool, educational resources, recognition through multiple awards, and also networking opportunities that support facility sustainability efforts.”

Visit ASHE’s Energy to Care website to learn more about the program. Also, learn how health care facilities can partner with ENERGY STAR and use its Portfolio Manager.

Erik J. Martin is a freelance writer based in Oak Lawn, Ill.