Plumbing manufacturers address hospital concerns

Easy installation, water conservation, and advances in hygiene and safety are features of the latest plumbing materials, fittings and fixtures as manufacturers strive to help hospitals improve operations.

Development of sensor-actuated faucets, valves and dispensers continues as a trend. Also, manufacturers are designing plumbing products to accommodate an increasingly obese population.

Helping to prevent the growth of Legionella bacteria is another design goal.

Achieving a balance

One of the challenges that vendors face is helping health care facilities achieve a balance between safety and compliance while maximizing resources. To achieve this goal, many plumbing products are designed with easy installation and maintenance in mind. Manufacturers also are offering deep sink basins and durable faucets to withstand daily use and abuse.

The threat of Legionella bacteria looms large. “We’ve seen an increasing awareness of the potential negative effects that stagnant water can pose to a hospital’s plumbing system. Stagnation is associated with Legionnaires’, a potentially fatal lung infection that is contracted by inhaling aerosolized water contaminated with Legionella bacteria,” says David Kachurak, director of business development for T&S Brass, Travelers Rest, S.C.

Health care facilities are particularly on guard against this disease because, while Legionnaires’ is fatal for about one of 10 people who contract it, the fatality rate rises to one in four when Legionnaires’ is acquired in a health care setting, according to the Centers for Disease Control and Prevention. “This pressing concern is being addressed by everyone involved in [health care facility] plumbing systems,” Kachurak says.

Patrick E. Keller, designer/inventor at Norva Plastics Inc., Norfolk, Va., agrees that the prevention of Legionella bacteria is a key driver in the development of plumbing products.

“Several hospitals have identified Legionella bacteria in their water systems,” Keller says. “In one hospital, the potable water system was out for four weeks and required staff and patients to use portable water. As a result, health care organizations are establishing water management programs and taking a closer look at plumbing fixtures to see if they contribute to the problem.”

Splashing and flow

Plumbing products recently introduced to the hospital market address many of these issues. For example, the ICS Sink with Selectronic IC Faucet available from American Standard, Piscataway, N.J., is designed to create a more hygienic environment.

The deep sink basin with sloped back minimizes splashing. The faucet’s sensor and electronic touchless controls prevent direct contact that could spread bacteria. In addition, the sink’s permanent EverClean surface inhibits the growth of stain and odor-causing bacteria, mold and mildew.

ChekPoint sensor faucets available from T&S Brass are designed to prevent water stagnation. If the faucet does not detect activation for 12 hours, it automatically turns itself on and runs for 30 seconds to purge any stagnant water that may be in the faucet or the connecting line.

“ChekPoint faucets prevent waste and avoid contamination,” Kachurak says. “In addition to the water- and energy-saving design, the ChekPoint line has adjustable settings that can be customized to control the faucet run time, how quickly water shuts off after removing one’s hands and whether an autoflush is desired if there is inactivity for 12 hours. ChekPoint also comes with a plain end spout, which produces a laminar flow without the need for an add-on aerator.”

Bradley Corp., Menomonee Falls, Wis., offers the solid-surface Terreon Deep Well Lavoratory for health care environments, which is designed to minimize splashing and aerosolization from the drain trap in sinks. The lavatory utilizes a molded, single-piece design that helps contain water, thus minimizing slips, falls and messes.

Water safety is a big concern among plumbing product manufacturers, says Greg Hunt, product manager for Chicago Faucets, Des Plaines, Ill. To meet this need, the company recently expanded its line of HyTronic faucets for patient care applications. Included are touch-free faucets that reduce the risk of transmitting surface pathogens. The faucets feature metering modes that set parameters for hand-washing as well as a scrub mode for longer run times in health care settings.

“Our Hygiene Flush mode lets hospitals set a time and duration to purge the plumbing lines of potentially dangerous stagnant water,” Hunt says. “Silver ion outlets and copper tubing are used to reduce bacterial growth. Angle stops with integral checks (to prevent potentially dangerous cross flow) and a thermostatic mixing valve provide protection from scalding but also feature a hot water bypass for thermal disinfection procedures.”

Products that incorporate evidenced-based design regarding antimicrobial and antibactericidal properties are definitely part of the patient room design consciousness among plumbing product manufacturers. This includes surface materials as well as actual product design, according to Bruce Keclik, product engineer at Just Manufacturing, Franklin Park, Ill.

To that end, Just Manufacturing offers plumbing fixtures, sinks and hand-wash stations featuring CuVerro Antimicrobial Copper Surfaces that kill pathogens within two hours of exposure and continue to kill bacteria 24/7 to maintain healthy environments in patient rooms, nurse stations, the ICU and ER.

Just Manufacturing also offers the Integra Drain Stainless Steel system, which seamlessly welds the drain to the sink. “This creates an integral drain-in-sink system, with no additional parts or rings, and features a grid strainer that provides a cleaner look. It also is hygienic because there is no seam for bacteria to build up in, from debris or waste,” Keclik says.

Norva Plastics Inc. has developed an anti-ligature, metered faucet that uses a laminar flow aerator made with antimicrobial materials.

“Most aerators draw air into the water stream, which can be a concern in health care facilities because the air is collected from the room around the faucet, and sometimes that air contains bacteria,” Keller says. “When laminar aerators are used, air is not drawn into the water stream, providing a crystal-clear stream of 100% water. Antimicrobial-protected faucet attachments offer even more protection by incorporating the natural protection of silver, which prevents the growth of a broad range of microorganisms.”

Conservation and safety

Toilets that continuously run can waste one to two gallons of water per minute, according to James Walsh, vice president of product management at American Standard. This issue is typically due to a clogged flush valve.

To combat this problem, American Standard has developed the UItima diaphragm flush valve. Equipped with an EvoLast diaphragm and DynaClean wiper spring, the valve is designed to resist premature deterioration, stopping valve run-on and conserving water.

“The wiper spring keeps the orifice clear of debris and mineral buildup while the diaphragm’s chlorine-resistant material delivers consistent performance and resists premature deterioration and failure from water treatment chemicals,” Walsh says.

Wall-mounted toilets are popular in health care facilities because of their cleanliness. However, many hospitals are replacing them with floor-mount toilets because they fear the product may detach from the wall while a patient is using it, according to Timothy Schroeder, sales staff engineer at Kohler Co., Kohler, Wis.

“It is more of a concern now that 127 million adults are classified as overweight, over half of them obese,” Schroeder says. “This has led to an increased number of heavier patients in hospitals and a greater risk exposure to wall-mounted fixtures.”

To meet this need, Kohler Co. has developed the ModFlexAdjust-a-Bowl, a floor-mount, back-outlet toilet with an adjustable height trap way, which can attach to the existing carrier and outlet. Floor-mount bowls have far greater load capacity than wall-mounted bowls, which makes the product safer, especially for heavier users.

“The adjustability of the trap is crucial for retrofits because outlet heights vary, even within the same hospital,” Schroeder says. “Using the existing carrier as opposed to replacing it with a floor outlet saves money. Because it can be costly to remove the carrier and then trench the floor to install a new outlet drain, it is more efficient and cost-effective to replace a toilet with the same outlet configuration.”

Restroom and shower room designs must keep pace with the growing trend toward an obese population. Yet, there is no third-party standard for bariatric design in commercial and institutional restrooms and shower rooms. This makes it difficult for architects to specify products in these applications, leaving much open to interpretation, according to Cassie Schneider, associate product manager at Bradley Corp.

In response to this trend, Bradley Corp. has introduced a line of SteadyCare Solutions that includes heavy duty-grade and bariatric grab bars and shower seats. Designed for use by people of all sizes in all types of commercial restroom and shower applications, these products can withstand high load ratings. SteadyCare grab bar models are rated at 550, 900, 1,000 and 1,250 pounds to provide ultimate user stability.

“A wide selection of grab bar configurations is available to furnish various restroom layouts and address a wide range of user needs, including Bradley’s new swing-up grab bars,” Schneider says.

Whitehall Manufacturing, a division of Morris Group International, City of Industry, Calif., offers vacuum plumbing systems that address many health care challenges, including infection control, high water and sewer costs, and expensive maintenance incurred with gravity waste systems.

“AcornVac provides significant savings in water supply and sewage disposal costs because the system uses only a half-gallon of water per flush,” says Kristin Kahle, vice president. “The system contributes to a healthier, more sanitary environment by eliminating the bacteria-laden flush plume and because vacuum pipes do not leak.” The company offers universal-design, ligature-resistant toilets that can be used with the system.

“We’ve seen more health care providers use vacuum plumbing systems to take advantage of standard office building lease rates, which are 20%-35% lower than medical office building rates,” Kahle says. “This is because they are not limited by the location of the existing sanitary sewer and water supply. Facility managers can add as many exam rooms with sinks that they want, on a quick construction timeline, with no need for expensive floor cuts or core drilling.”

Future trends

While technologies that promote durability, tamper resistance and prevention of patient self-harm are well understood and can be applied with ease, infection control is a dynamic arena looking forward, according to Schroeder.

“Kohler is looking at alternative designs around common trouble areas of some currently employed designs,” Schroeder says. “They include changes in materials to naturally antimicrobial, new coatings, active disinfection and alternative controls/valving.”

In terms of materials, Schneider of Bradley Corp. sees a trend moving away from stainless and laminates toward solid surface and natural quartz.

“This shift may be driven by the preference for a more natural aesthetic, along with greater durability, sustainability and longer life cycles,” Schneider says.

Beyond these issues, Walsh of American Standard foresees advances in hygiene and connected plumbing products that can prevent and identify leaks and provide maintenance alerts. This will provide facilities with data about water usage and meeting preventive maintenance needs.

Neal Lorenzi is a freelance writer and regular contributor based in Mundelein, Ill.

HYGIENIC PERFORMANCE

The ICS Sink with Selectronic IC Faucet is designed to create a more hygienic environment. American Standard

SANITARY SURFACE

The Cu-J-770-1-S Surgeons Scrub Sink features 18-gauge CuVerro antimicrobial copper-nickel touch surfaces. Just Manufacturing

NO HANDS

HyTronic touch-free faucets reduce the risk of transmitting surface pathogens. Chicago Faucets

SPLASH RESISTANT

The Terreon Deep Well Lavoratory is designed to minimize splashing and aerosolization from the drain trap in hand-hygiene sinks. Bradley Corp.

FLOOR SHOW

ModFlexAdjust-a-Bowl, a floor-mount, back-outlet toilet, can attach to the existing carrier and outlet. Kohler Co.

SAFE AND FLEXIBLE

The Universal Suicide-Resistant Shower Handle can be customized to fit virtually any shower mixing valve. Norva Plastics Inc.

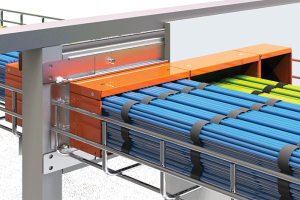

LETTING IT FLOW

Sensor faucets include an auto-flush feature that runs water for 30 seconds after 12 hours of inactivity to prevent water stagnation. T&S Brass

ATTRACTIVE AND FUNCTIONAL

Bathrooms designed with suicide-resistant products need not look institutional. Whitehall Manufacturing