Power equipment firms unveil new innovations

Hospital demands for emergency power supply systems have changed in recent years. In response, manufacturers of generators and related equipment have upgraded their systems to improve health care operations.

Facilities managers are looking for generators that can take on loads that were once considered noncritical, including HVAC and information technology, to ensure total hospital operations for the duration of an outage. Expectations are that power systems maintain similar costs and footprints, while delivering the same performance in output, emissions and fuel consumption.

Additionally, the growth of community-based health centers and other remote facilities spread across a large area increases the complexity of service and maintenance challenges. Remote monitoring and control are essential for these situations.

The continued growth of decentralized critical-care facilities will drive the need for smaller emergency power supply systems that are optimized to cost effectively protect against short outages or disruptions in power, according to Zach Dean, power generation regional sales manager with MTU America Inc., Mankato, Minn., part of the Rolls-Royce Group. “Traditional emergency standby systems based on diesel or natural gas are a great fit for these situations.”

Recent innovations in generators, automatic transfer switches (ATSs) and uninterruptible power supplies (UPSs) are improving the performance and reliability of many of these health care facilities.

New for generators

When it comes to generators, the adoption of gaseous-powered sets is growing, according to Colette Weiser, standby marketing leader at Cummins, Shoreview, Minn. Benefits include an uninterrupted supply of fuel, especially during long-term outages. “Also, more low-cost, easy-to-install remote monitoring systems are available, enabling facility managers to more easily monitor and respond to changes in their power systems,” Weiser says.

Another trend is the addition of capabilities for connecting mobile generator sets during maintenance routines or extended power outages due to natural disasters. “Hurricane Sandy and Hurricane Irma demonstrated that on-site backup power can be compromised by flooding and other structural damage, especially for below-grade installations,” says Mark Tooker, energy systems engineer for Caterpillar Inc., Deerfield, Ill.

Also, as hospitals replace outdated power systems, there is more demand for generator sets with high power densities that deliver more power from the same physical footprint. “With advances in engine technology, we’re now able to deploy a 1,250-kilowatt (kW) generator set in the same floor space previously occupied by a 750-kW unit, which helps to reduce total costs for site preparation, transportation and installation,” Tooker adds.

In 2020, Caterpillar Inc. introduced two generator sets that are suitable for mission-critical health care applications: the Cat 3516E diesel generator set and Cat G3520 gas generator set.

“The 3,000-kW Cat 3516E diesel generator set offers a 19,900-pound weight reduction over a competitive product offering the same power output while occupying 11% less floor space,” Tooker says. This helps to reduce overall site preparation and installation costs.

The Cat G3520 is the first Environmental Protection Agency (EPA)-certified natural gas generator set rated at 2.0 and 2.5 megawatts (MW), according to Tooker. It is engineered with quick starting and loading capability, and meets the National Fire Protection Association’s NFPA 110, Level 1, Type 10 standards.

In addition, Caterpillar offers temporary connection boxes for linking a mobile generator set to a building’s electrical system, delivering temporary power in seconds.

Caterpillar also offers combined heat and power (CHP) enclosures for natural gas-fueled Cat G3520H generator sets. They provide electricity for electrical loads and heat energy for a facility’s thermal requirements simultaneously. The enclosures reduce the lead time for implementing CHP solutions and eliminate the need for outsourcing.

Cummins’ 3,000- to 3,500-kW generator set, powered by Cummins’ 95L diesel engine, is one of the largest standby generator sets available, according to Weiser. It provides emergency standby power with various mission-critical application features such as redundant starters and batteries, closed-crankcase ventilation, redundant filter system/swap on the fly and an oil makeup system.

“At 2,500 kW, Cummins has extended its QSK60 generator set platform while focusing on key applications in a small footprint,” Weiser says. “Features include duplex filters, redundant starters and an oil makeup system.” To meet emissions and air quality standards, Cummins offers EPA Tier 4 stationary emergency-certified diesel generator sets, low NOx versions of several models and other emissions-reduction solutions.

To utilize a generator in a local utility’s curtailment program, the unit must be Tier 4 certified, according to Bradley Meissner, product manager for Kohler Power Systems, Kohler, Wis. In response, the company has introduced the KD1250-4, KD2500-4 and KD3250-4, which meet Tier 4 standards. These units offer simple selective catalytic reduction-only emissions technology and include factory enclosure options at 1,250 and 2,500 kW.

The Kohler APM603 generator controller includes a data-logging feature that allows for easy data collection and download to satisfy Joint Commission requirements. It also provides communication protocol support native to the controller so a hospital can integrate generator data and operational alerts into its building management system. Communication support includes Modbus RTU and TCP, Simple Network Management Protocol and BACnet.

MTU America has introduced the mtu master control panel, which provides a scalable option for hospitals to help them optimize their power generation systems. It eliminates the need for traditional switchgear, which requires a separate cabinet section for each generator set. “Instead, the master control panel can accommodate multiple generator sets, allowing flexibility to bring more online as a facility expands,” Dean says. “It provides a high level of monitoring, control and visibility with a lower equipment cost.”

Generac, Waukesha, Wis., manufactures generators that are designed for use in mission-critical applications. When these generators are equipped with auxiliaries such as heavy-duty heaters and batteries, and installed and maintained properly, they start up in seconds and provide utility-grade replacement power for long periods of time to ensure continuity of services, according to Richard Lincoln, senior director for global product management.

“Generac’s most recent addition is the G49L, 1,000-kW natural gas generator,” Lincoln says. “It has been optimized to perform in demanding applications with a more resilient and cost-effective fuel when compared to diesel platforms at a fraction of the emissions.” The 49L has a fast-start fuel system and can run in demand-response applications.

ATS advances

Eaton, Charlotte, N.C., recently introduced a UL 1008-listed bypass isolation ATS with enhanced safety and serviceability features and ratings of up to 3,000 amperes. It provides self-acting redundancy and automatic restoration of power (within 10 seconds for Type 1 and Type 2 essential electrical systems) when the normal power source is interrupted, which can occur during routine maintenance of the ATS or automatic bypass switch.

In addition, dual draw-out power switches allow in-compartment isolation of the automatic bypass switch and ATS for regular exercise or testing to maintain equipment reliability. The draw-out feature also facilitates easy removal of either power switch for bench-level maintenance or replacement. “A dedicated control compartment with a maintenance isolation switch mitigates shock hazard by reducing the risk of exposure to system and control voltage,” says Charlie Hume, product manager for ATSs at Eaton. “Also, an integral slide-out panel provides easy access to components during service.”

Hospitals value the bypass isolation transfer switch, which includes two switching mechanisms to transfer a load between sources, according to Nicole Dierksheide, associate director of marketing for electronics at Kohler Power Systems. The duplicity of switching mechanisms allows for loads to be continually powered through one mechanism while the other mechanism is being serviced. “Kohler offers a variety of bypass isolation transfer switch options to meet these needs,” Dierksheide says. “The Kohler ATS controller also offers load management functionality, allowing the management of individual loads from the generator or the ATS.”

Russelectric, Hingham, Mass., a Siemens business, offers a line of 30-cycle-rated automatic transfer and bypass/isolation switches that are customizable. “Bypass/isolation transfer switches are typically used in hospitals,” says John Stark, marketing communications supervisor. “The ATS portion of a bypass unit can be bypassed easily and withdrawn to perform maintenance or emergency functions. In addition, because of recent code changes for selective coordination, 30-cycle-rated transfer switches are becoming more common.”

Florham Park, N.J.-based ASCO Power Technologies, a business unit of Schneider Electric, recently expanded its critical power management appliance offerings to include touch-screen annunciators, power management gateways and touch display interfaces for its ATSs, providing modular, scalable solutions for monitoring emergency power supply systems.

“They are quick and easy to configure, and deliver rich data to enhance the connected layer with capabilities, such as backup power test reports that streamline compliance, comprehensive alarm and thermal monitoring for real-time, 24/365 notification, and remote operation to reduce arc flash and shock hazards,” says Shannon Dynge, regional sales director.

UPS innovations

Regarding UPSs, Eaton has introduced several versions of products that are intended for medical imaging applications with repetitive high-inrush loads. The company offers a variable module management system, which optimizes UPS efficiency in multiple imaging machine suites. “This allows the UPS to flex and optimize its capacity instantly in response to load levels — minimum capacity (best efficiency) when imaging equipment is idle and full power immediately available when the imaging program demands,” Hume explains.

MTU America recently expanded its mtu portfolio to include dynamic uninterruptible power supply (D-UPS) with the mtu Kinetic PowerPack. “With a D-UPS, there is no wait time for power to be restored in the case of a power outage; it is immediately activated, thus protecting life-critical loads that cannot afford to go down for even a few seconds. These systems also have a lower total cost of ownership than traditional UPS systems for greater than 1-MW power over their 20-year lifespan,” Dean says.

Vycon Inc., Cerritos, Calif., offers the VDC-XXT flywheel system, which provides 24/7 clean energy storage. Paired with three-phase UPSs, the flywheel technology provides DC power capacity using the kinetic energy of a high-speed flywheel for instantaneous power backup. Upon a power failure, the VDC-XXT will supply seamless direct-current energy, allowing the UPS to quickly transfer to the facility’s backup generators.

Vycon’s technology incorporates a high-speed motor generator along with active magnetic bearings that levitate and sustain the rotor during operation. System operation and performance are monitored via a touch-screen panel as well as communication capabilities that include operating parameters, alarm status, and local and remote shutdown. “This simplifies operation while enabling the flywheel systems to charge and discharge at high rates for countless cycles that outperform batteries,” says John Jeter, Vycon’s director of sales.

Looking ahead

What advances do experts see for the near future? Tooker of Caterpillar Inc. sees a growing opportunity to use generator sets powered by natural gas in standby health care applications.

“Generator sets that use pipeline natural gas help facilities bypass the need for large storage tanks with 48 to 96 hours of diesel fuel, an increasingly mandated requirement for hospitals,” he says. “They also provide system design flexibility since they can be positioned wherever space is available in the facility — even on the roof — without having to accommodate diesel day tanks.”

Natural gas generator sets also allow health care facilities to leverage their standby assets in demand management situations.

Neal Lorenzi is a freelance writer and regular contributor based in Mundelein, Ill.

REMOTE CONTROL

Cat Connect remote access monitoring offers real-time collection and remote monitoring of site performance data to help operators track and manage the operation of their power systems. Caterpillar Inc.

NOT FUELISH

his new 1,000-kW gaseous generator has been optimized to perform in demanding applications with a more resilient and cost-effective fuel when compared to diesel platforms at a fraction of the emissions. Generac

WHEN SECONDS COUNT

This transfer switch with integrated Cam-Lok receptacle power panel serves as a docking station for quick connection of a temporary generator that will supply critical electrical loads with emergency power during a utility outage. Eaton

YOUR CHOICE

This full line of 30-cycle-rated automatic transfer and bypass isolation switches is customizable. Russelectric

DOUBLE DUTY

The Kohler KD Series diesel generators at 1,250, 2,500 and 3,250 kW are certified at Tier 4 EPA air quality standards for non-emergency applications, including prime power, peak shaving and curtailment programs. Kohler Power Systems

CHECKING IN

Cummins Power Command Cloud remote monitoring provides access via workstation, tablet or smartphone, allowing users to check system status, identify faults and access critical notifications. Cummins

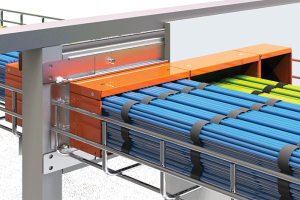

READY TO RUN

The mtu Kinetic PowerPack is a dynamic uninterruptable power supply that offers immediate power with a lower total cost of ownership and smaller space claim than a static UPS system with batteries. MTU America Inc.

MAKING A CONNECTION

The ASCO Series 300 Quick Connect Power Panel offers a reliable and convenient way to connect a temporary generator or load bank through a single device. ASCO Power Technologies, a business unit of Schneider Electric

SPINNING WHEELS

The VDC-XXT flywheel energy storage system improves health care system uptime and eliminates the environmental hazards, costs and maintenance associated with lead-acid-based, backup batteries. Vycon Inc.