Flooring manufacturers meet hospital challenges

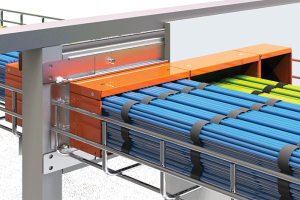

Image from American Biltrite

Hospital flooring continues to evolve, offering improvements in safety, comfort, acoustics, mobility, cleanability and aesthetics. It also provides stability and traction for foot and wheeled traffic to minimize the risk of injury.

Additionally, smart use of flooring can maximize efficiencies through faster installation and ease of maintenance, help improve patient satisfaction through noise reduction, and implement colors and patterns that support a healing environment.

Flooring choices

Resilient sheet flooring and luxury vinyl tile (LVT) are widely chosen because of their ability to meet a range of requirements. Also, new technology has brought more colors and patterns, better wear and installation features, and improved chemical- and stain-resistance as well as antimicrobial enhancements.

There has been a growing need for flexibility, repurposing and multipurpose spaces over the past few years, according to Sandra Soraci, EDAC, LEED AP, NCIDQ, senior channel marketing manager at Armstrong Flooring, Lancaster, Pa.

“Modular construction has its place and flooring is a foundational interior finish that can be part of this flexibility, while supporting brand standards for the health system,” Soraci says. “Environmental services (EVS) departments continue to do more with fewer people and, as a major capital investment, the floor finish can replace a rigorous maintenance protocol while reducing the associated person-hours to maintain.”

Because of pandemic-related challenges, health care organizations also have been paying close attention to the cleanliness and durability of their flooring, while still trying to foster a sense of calm via aesthetics.

“The concept of the patient experience continues to drive change,” says Fred Reitz, vice president of commercial sales at AHF Products, Mountville, Pa. “Designers are specifying products that resemble the home experience during renovations and new builds. These products feature warm designs and offer coordinating colors and patterns.”

Ergonomics is playing a larger role in flooring specification because it’s critical that hospitals enhance working conditions. Nurses often walk 4 to 8 miles a day during their shifts, which can lead to injuries such as back and knee pain, bone spurs and plantar fasciitis.

“To address these ergonomic challenges, flooring must strike the right balance between energy restitution and force reduction,” says Mark Huxta, director of sales for health and wellness at Ecore International, Lancaster, Pa. “Essentially, flooring that is too hard puts additional stress on joints, while surfaces that are too soft can contribute to fatigue and compromise balance.”

Acoustics is another big challenge, says Casey Johnson, director of health care business development in North America at Forbo Flooring Systems, Hazleton, Pa. “Creating an environment that supports acoustics helps improve care, reducing readmissions caused by the inability to hear or understand instructions,” Johnson says. “Proper acoustics also help reduce the stress of patients and staff.”

Another challenge is high turnover in EVS departments, which means hospitals must continuously train new employees. Anything that flooring vendors can do to make the work of EVS easier is beneficial, whether it’s providing simple instructional infographics or in-house training. “It is important for manufacturers to build relationships with EVS directors and be available to respond to questions or concerns,” says Margaret Bartholomew, marketing manager of health care at Tarkett North America, Solon, Ohio.

Outpatient spaces

Additionally, there are differences in flooring requirements — regarding product life, cleanability, aesthetics and wayfinding — between large hospitals and smaller offsite ambulatory facilities.

“Inpatient facilities typically use homogeneous and heterogeneous sheet products, while outpatient settings typically use heterogeneous sheet products and LVT,” Soraci says. “The post-acute care market typically uses a combination of soft surfaces and resilient products.”

Differences in selection are linked to budget, floor space and utilization needs, says Catherine del Vecchio, vice president of marketing for the flooring division at American Biltrite, Sherbrooke, Canada.

“Hospitals use a variety of flooring in different areas — from rubber sheet flooring in operating rooms to LVT in waiting rooms,” del Vecchio says. “A variety of patterns, colors and wayfinding indicators can be created for larger projects. For smaller clinics, flooring selection can include just one type of product and even one stock-keeping unit selection. For example, LVT can be used throughout smaller facilities, from the entrance to the waiting areas and exam rooms.”

For smaller outpatient facilities, the priority attributes of flooring are aesthetics, cleanability and affordability, says Julie Stegeman, health care segment manager at Interface Inc., Atlanta.

“Because these spaces often are leased and have fewer technically trained cleaning services, managers must pay close attention to price and ease of cleaning to make sure the flooring fits the space’s immediate needs,” Stegeman says. “As a result, we see more LVT, vinyl sheet and carpet tile specified in outpatient facilities.”

Something new

Among new products available to hospitals, Armstrong Flooring has introduced three heterogeneous sheet collections: Asana, Nidra and Zenscape. Embodying human-centered properties for relieving stress and anxiety, the collections are inspired by meditative and restorative patterns found in nature. Available in 6-foot, 9-foot and 12-foot roll widths, they offer size flexibility to minimize seams and cut down on installation time.

“Diamond 10 technology coating eliminates the need for polish, reducing the total cost of ownership, as well as offering scratch-, stain- and scuff-resistance, which provides durability,” Soraci says. “All three collections are free of ortho-phthalates and heavy metals, have low volatile-organic compound emissions and are FloorScore certified.”

Patcraft, Cartersville, Ga., has developed Within, a coordinating plank and sheet resilient collection available in abstract and wood visuals. Designed to meet the needs of health care environments, the wood visual is embossed in register, providing texture for a more realistic wood look; it is available in nine warm colorways. The abstract pattern is available in eight colorways of fresh neutrals and nature-inspired hues.

The collection’s wood visual is available in a heterogeneous sheet format and in planks, and the abstract pattern is available in the same sheet format and in tiles. “The abstract visual’s pattern features tranquil colorways that can refine the hospital experience in patient rooms, lobbies and clinical areas,” says Keith Richardson, director of performance markets.

After witnessing the success of its nora rubber and Interface LVT in the health care market, Interface Inc. recently expanded its resilient portfolio to include its first vinyl sheet products. They provide high-performance solutions for patient rooms and other spaces that require seamless installation, ease of maintenance, stain resistance and slip resistance, along with durability, says Stegeman. “With our LVT, vinyl sheet and nora rubber options, we can provide a variety of aesthetic options to create a beautiful, integrated resilient flooring system,” Stegeman continues. “Also, all of the flooring products are carbon neutral across their full life cycle through the third-party-verified Carbon Neutral Floors program.”

Interface also has introduced a biophilic health care collection of carpet tile, LVT and vinyl sheet that aims to connect facility occupants with the natural world through an integrated, cohesive design.

American Biltrite offers Sonata Elements, an LVT that mimics the look of striated carpet tiles. “Its timeless look can be coordinated with other finishes and won’t go out of style,” del Vecchio says. “It was introduced at the beginning of the pandemic, making it a success as facilities were replacing soft-surface flooring with hard surfaces that can be easily cleaned and disinfected.”

Durability challenges

AHF Products has introduced an AHF Contract Portfolio that includes new vinyl-based tile, offering lower maintenance and lifecycle costs when compared to traditional vinyl composite tile, with colors developed for commercial environments.

“A 20-mil wear layer is topped with AHF’s Urethane Plus with Ceramic Bead finish,” Reitz says. “The 2.5-milimeter gauge construction provides a durable, stable floor that withstands heavy rolling loads, is resistant to scratches and stains, and offers scuff- and slip-resistance.” The company also offers Cleantivity antimicrobial technology on many of its wood and resilient floors.

Tarkett North America offers the iQ vinyl sheet and tile collections, which simplify cleaning and infection control. The material can be restored by dry buffing — with no refinishing needed for the life of the floor.

“We continue to update these products visually with soothing, organic patterns and color palettes that create safe and comfortable spaces for both patients and staff,” Bartholomew says. “Our latest iQ Granit and iQ Eminent collections will be introduced later this year.” The iQ collections are certified to be asthma- and allergy-friendly by the Asthma and Allergy Foundation of America.

Ecore International has introduced Aurora Motivate, a hygienic, easy-to-clean flooring system. The resilient rubber sheet product features a polyurethane-coated, calendared-rubber wear layer that is fusion-bonded to a vulcanized composition rubber backing. “It is designed to provide ergonomics and comfort for employees, and reduce the severity of injuries resulting from trips and falls,” Huxta says. “The flooring system also enhances acoustics and comfort underfoot.”

Forbo Flooring Systems asked its health care customers: Do you consider your current flooring an asset or a liability? “We listened and developed a series of solutions that convert flooring from a liability into an asset,” says Johnson. The company created Forbo EZvations, which includes the Forbo 100 adhesive system, ArmorCove and Marmoweld ETU flooring products. They are designed to reduce costs through efficient use of materials, improved labor efficiency and immediate occupancy.

Stonhard, Maple Shade, N.J., has unveiled Stonres RTZ-2, which offers the same performance as traditional Stonres RTZ with a new decorative option.

“With both larger chips and translucent chips available, Stonres RTZ-2 comes in a wide-ranging palette featuring 12 new colors that are sought after by architects and designers,” says Chris Trageser, product manager. “RTZ and RTZ-2 are ideal for operating rooms, corridors and patient rooms.” RTZ resembles traditional epoxy terrazzo, but no stripping or waxing is required and it is easy to clean.

Rather than introduce new flooring materials to the hospital market, Bona, Englewood, Colo., offers the Bona commercial system resilient floor solution, which can renovate existing flooring materials, such as resilient, LVT and rubber flooring, instead of replacing the floor.

“It’s a whole new way to view floor maintenance,” says Todd Weyhmiller, director of product management. “The system can bring old resilient floors back to life, even changing the color and design. It also can reduce downtime and allow hospitals to resume operations within a few hours or days, depending on the amount of flooring being renovated.”

Looking ahead

What advances do hospital flooring manufacturers see ahead? For one thing, hospitals will continue to focus on specifying flooring products that solve multiple problems and challenges, including performance, sustainability, longevity and evidence-based design. Also, demand for sustainability in flooring will continue to increase and, because of widespread labor shortages, health care facilities will look for maintenance solutions that save time and resources.

LOCALLY SOURCED

The ABPure Nfuse rubber sheet and tile flooring products are made in North America. American Biltrite

EYES HAVE IT

A creative installation of Tarkett’s Event, Victory and Contour LVT draws the eye to different zones of this medical lobby. Tarkett North America

FOR EVERY TASTE

Patcraft’s Within is a coordinating plank and sheet resilient collection available in both abstract and wood visuals. Patcraft

WHAT’S NEW

Stonres RTZ is a seamless, poured-in-place floor that is now available in new design options. Stonhard

NEW LIFE

The Bona commercial system resilient floor solution is a process that can renew a health facility’s old resilient floors in a safe, quick and cost-effective manner. Bona

SEEING AND HEARING

Marmoleum provides wayfinding solutions and acoustic properties for health care facilities. Forbo Flooring Systems

TOUGH PERFORMER

he AHF Contract heterogenous and homogeneous vinyl sheet line provides a durable floor that withstands heavy rolling loads. AHF Products

NATURAL FEATURES

Forest Rx high-quality wood visual flooring is used in an administrative area at UW Health in Madison, Wis. Ecore International

HIGH PERFORMANCE

Looped, from the Interlaced collection, is a perfect fit for healing spaces that require seamless installation, ease of maintenance, stain resistance and slip resistance, along with durability. Interface Inc.

Neal Lorenzi is a Mundelein, Ill.-based contributor to Health Facilities Management.