Automated savings

As energy costs rise and climate change impacts our environment, building automation systems (BASs) can help reduce both the cost of energy and the impact of health care facilities on the environment.

As energy costs rise and climate change impacts our environment, building automation systems (BASs) can help reduce both the cost of energy and the impact of health care facilities on the environment.

However, the key for energy savings and reduced environmental impact depends on several things: operational analysis, systems design, user training, and data collection and administration. Without these processes, most BASs will not meet expectations nor provide the energy and cost savings anticipated.

Traditionally, BASs controlled and monitored heating, cooling, ventilation and air conditioning (HVAC) systems. Today, numerous building systems, such as interior and exterior lighting, elevators, access control, surveillance, fire alarm, parking controls and more can be operated and monitored via an integrated BAS.

Moreover, building automation control has come a long way in recent years, evolving from proprietary systems and protocols to standard-compliant architecture that is backward- and forward-compatible.

In addition, modern BASs provide remote monitoring and alerting capabilities that can warn operators of a system or component failure, an abnormal condition or an increase in system energy consumption within a building, allowing for off-site monitoring after hours, timely response and correction.

New BAS technologies

With the tremendous growth in wired and wireless network technologies over the past decade, the natural transition to these types of networks was inevitable for the building systems industry. Every new facility today is built with an extensive data network as part of the infrastructure.

Also, wireless systems are almost an automatic feature in every project. It is logical for the BAS to take advantage of these systems and the different technologies available to provide greater efficiencies, ease of use and reduced costs. Some examples of different wireless systems that the BAS can utilize include:

WiFi (802.11). All health facility professionals are familiar with wireless local area network systems common in their hospitals. Depending on the design and coverage patterns, these networks offer reliable transport for BAS information throughout the facility.

Distributed antenna system (DAS). The DAS is becoming prevalent in most health care facilities.

In many areas, the DAS is mandatory for emergency responder radio systems. In fact, the latest revision of the International Building Code (2010) requires DAS for emergency communication purposes in facilities of certain classifications, and many local authorities have developed their own requirements.

Although, traditionally, the DAS has not been a transport for BAS, it can be used to transport multiple wireless systems.

|

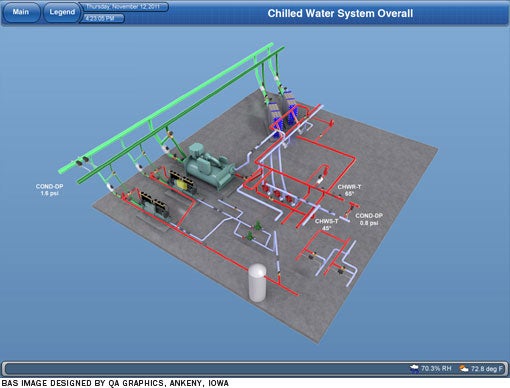

| A chilled water system displayed on a building automation system. |

ZigBee (802.15.4). ZigBee is a specification for simple, low-cost, high-level communication protocols using small, low-power digital radios based on the Institute of Electrical and Electronics Engineers' IEEE 802.15.4-2003 standard for Low-Rate Wireless Personal Area Networks, such as wireless light switches with lamps, electrical meters and other devices via short-range radio needing low rates of data transfer.

Wireless technology can be a cost-effective solution for BAS, providing mobility for facility staff as well as integration to different networks. Traditional BAS protocols like BACnet and LONWorks can be encapsulated in Internet Protocol packets and transported over the data network, allowing for real-time, remote interface with building systems and controls. For applications with real-time requirements, a quality of service configuration can be set to ensure these applications receive appropriate priority to meet performance goals. The same capabilities are true for a wired system as well. Any workstation with access to the network can provide monitoring and control of the BAS.

So what does this mean in regard to efficiencies and ease of use? The use of existing data networks can provide a platform on which a BAS will ride, creating great opportunities and flexibility for systems monitoring, access and control. This can be used for HVAC, plumbing, power, lighting, elevator, automated parking, surveillance, access control and landscape systems.

Real-time remote interfaces allow monitoring and control by staff and troubleshooting by systems specialists. There are important safety advantages to integrated building systems as well. For example, an alarm triggered by the fire system may be programmed to close fresh air dampers and turn on exhaust fans in that portion of the building. These systems also can capture and log data from the various systems in the building and generate graphs to show performance history and trends.

Energy control in the field

Of course, all these features only make sense if they perform in the field. Following are two case studies showing the energy-saving advantages of an advanced automation system:

Swedish Medical Center, Issaquah, Wash. In the summer 2011, Swedish Medical Center opened a new greenfield site medical center. The design team knew it would have to do better than merely relying on an energy model to convince the hospital it had reached the target Energy Use Intensity (EUI) of 150.

Upon completion of the design, Swedish purchased an enhanced graphics option for its maintenance and engineering staff to monitor and trend energy use within its newly completed hospital tower and medical office building. A feature of this program is to roll up data into a clearly presentable dashboard for easy interpretation.

At an executive report level, this data is both informative and empowering. Management may want to know how the hospital is performing, while facilities can delve into the whys. This can be accomplished through pie charts, graphs or meters.

Think of the Toyota Prius dashboard and consider how looking at a simple performance diagram can have multiple effects. First, it can tell drivers how far they can expect to go on their current fuel supply. Second, it can give them real-time performance evaluation (if they stomp on the gas, they get 2 miles per gallon). As all Prius drivers can attest, this kind of knowledge has one immediate effect: to modify behavior and maximize fuel efficiency.

At Swedish, there are literally thousands of direct digital control (DDC) points gathering information on all the main systems. For electrical loads, chillers, pumps, fans, lights and equipment are monitored. Optimally, the BAS would be able to monitor these categories separately. Within the equipment category, it is preferable to separate out elevators, general equipment (plug loads) and imaging. The more loads that can be separated and monitored independently, the more the facility engineers can home in on where the energy costs really are.

In the Swedish Issaquah facility, natural gas primarily is used in the kitchen and for sterilization, hydronic reheat, preheating ventilation air and domestic hot water generation. Of these, reheat is the primary gas use, when not enough heat is being captured for reuse by the heat recovery chiller. With meters in place on the various systems, the BAS can be programmed to give immediate insight into how much gas is being used and for what purpose or system.

Also being monitored is the electrical load throughout the facility. In this case, it was observed that lights were being left on more hours per day than actually needed and the resultant heat was skewing the available heat being recovered. Once the hospital was no longer being heated by lighting, other heat sources could be better utilized.

The system is designed to work like this: First, heat from process cooling (such as for intermediate distribution frame rooms) is collected from fan coil units. If this is not enough heat, then the large coils placed in the exhaust air stream within the general building exhaust extract heat, in lieu of exhausting to the outside. Finally, heat can be recovered from the return air system.

The BAS is set up to monitor and predict what loads will be available and when to turn on the auxiliary boilers, which is considered the heating method of last resort.

From the dashboard readout, the hospital's energy use can be measured against any benchmark. The EUI target of 150 for the Swedish Issaquah facility is set against the Commercial Building Energy Consumption Survey data gathered by the Department of Energy.

For hospitals, this EUI number has traditionally averaged 270. The dashboard can show in real-time how the energy use is stacking up against this design baseline. In the facilities department, the data can be analyzed and the systems fine-tuned for better optimization and energy efficiency.

Providence Regional Medical Center, Everett, Wash. Despite all of the potential opportunities to utilize the BAS for monitoring, trending and optimizing operation, this can be accomplished only if the facility engineer thoroughly understands the system.

Quite often, as new facilities or facility additions are completed, the engineers are not able to interface with the systems until after substantial completion and the owner takes possession.

The owner of the Providence Regional Medical Center committed two facility engineers to work full time as part of the commissioning team with the commissioning agent, control contractor and mechanical contractors. The engineers were involved from startup, through the functional test period and the final commissioning of the systems.

This unique experience actually was recommended by the commissioning agent, and allowed the facility engineers to be involved in the decision-making process and to gain intimate experience with the system components, operation and design intent.

As part of the process, the facility engineers were immersed in the BAS sequence of operation and they worked hand in hand with the control contractor in creating the BAS dashboard graphics and user interface.

Normally, system knowledge that is gained through startup and commissioning leaves with the construction team and commissioning agent. But, with this approach, the history of the decisions and system knowledge stayed local with the hospital.

Facility professionals have made a commitment to the facility users and staff that the building will be operated efficiently and, to validate this, the BAS will be utilized to provide the energy-savings data for hospital newsletters and other communications.

The automation system is used primarily to control systems and monitor status. At the heart of the systems are hundreds of data points reporting whether systems are operating within design parameters. When an operation fails or exceeds a set limit, an alarm message is sent to the system computer. Critical alarms also are sent to pagers carried by facility staff.

The BAS also can turn certain systems to standby mode when not in use. For instance, operating rooms are energy intensive and can require 25 air changes per hour. When these rooms are not in use, their supporting systems can be automatically scaled back. By computer schedule or manual override, the rooms can be back in full "on" mode within 20 minutes.

Another way the BAS helps to save energy is the constant monitoring of zones and the potential for temperature reset. If all the terminal units within a zone are satisfying demand, the system automatically will reset the supply air temperature to a higher level. Cooling with higher temperature air is a good way to lower a building's EUI.

In addition to the DDC points being monitored, there are five meters that give the following data: electrical energy consumption (showing instant consumption that provides continuous trending), electrical energy consumption (showing daily, monthly and annual trending), a gas meter for the kitchen (the central utility plant is metered separately), a water meter and an outside air temperature meter.

Because meters can cost thousands of dollars, the addition of more metering is always a trade-off between first cost and the ability to isolate and fine-tune separate systems or buildings.

Savings for the long haul

Today's BASs provide health care facilities with a variety of options when it comes to monitoring, controlling and reducing energy costs. However, these advanced technologies must be combined with staff training to provide savings for the long haul.

Tod Moore, RCDD, CDCD, is principal of IT architecture at Sparling, Seattle, and Jill Connell, P.E., HFDP, LEED AP, is associate and senior project manager, CDi Engineers, Lynnwood, Wash. They can be reached at tomoore@sparling.com and jconnell@CDiengineers.com, respectively.

| Sidebar - Successful BAS implementation requires a team approach |

| Even with all the advances in building automation system (BAS) technologies, control systems primarily communicate on open protocols, such as BACnet, LonTalk or MODBUS at the sensor level. It's not until it reaches the backbone level that the protocols change to an Internet Protocol (IP) platform. A control unit, often a programmable logic controller, translates the different inputs from the BAS sensor points to an IP signal for transmission on the data network. This is where it gets interesting from an operational and organizational standpoint. Today, the BAS controllers usually are located in the telecommunication rooms, along with a host of other systems. This is where the information technology (IT) and facilities departments converge and it can create issues. Often, the facilities department or the BAS manufacturer wants a stand-alone network for its systems, yet the IT department does not want foreign networks in its spaces. IT wants to manage and maintain all the network equipment and will resist other non-IT staff working within the network and possibly creating problems that they have to fix. This gets even more complicated when it comes to the BAS servers, which could be located in the data center. Again, these proprietary servers are not managed by the IT department but, rather, the BAS vendor. The IT department is often reluctant to allow non-IT personnel into their data center; yet it doesn't want the responsibility of managing the BAS servers because IT doesn't own them nor do they have the same upgrade and refresh cycles as the other systems. To deal with this, it is crucial to bring the IT department, facilities department and BAS vendor together to plan the BAS design and deployment. This will set the roadmap for network topology, responsibility and operation before systems are laid out and procured. It also will reduce time, cost and headaches during the construction and implementation phase. |