Advances in plumbing equipment offset costs

Health facilities professionals must weigh a number of considerations when selecting plumbing fixtures and fittings. Infection prevention, conservation and accessibility as well as meeting the needs of the growing number of bariatric patients are all part of the specification equation.

In addition, there is a move away from typical commercial-looking products. Health care providers are seeking plumbing fixtures and fittings with a comforting aesthetic that make patients feel at home. Reliability, durability and lower lifetime costs also are priorities.

With economic pressure on the health care industry, hospitals have a heightened awareness of areas that can be managed better to control costs and improve the patient environment. Plumbing fixtures and fittings ultimately play a part in meeting both of these goals.

Barriers to infection

The CuVerro line of antimicrobial sinks from Elkay Commercial, Oak Brook, Ill., is a good example of how copper-based materials provide the best solution for infection control, according to Gary Israelson, product manager for commercial faucets at Elkay. “We see an increase in copper-based products in hospitals. This material kills 99.9 percent of the following bacteria within two hours of exposure: Methicillin-resistant Staphylococcus aureus, Enterobacter aerogenes, Pseudomonas aeruginosa and Escherichia coli 0157:H7. Copper-nickel material continuously kills bacteria,” he says.

Providing another example of infection control, Zurn Industries LLC, Erie, Pa., has developed the EcoVantage with SilverShield antimicrobial technology for plumbing surfaces. It features a permanent antimicrobial glazed ceramic surface, which inhibits the growth of stain- and odor-causing bacteria, mold and mildew. Suitable for health care environments, the EcoVantage product line with SilverShield improves sanitation while minimizing the need for harsh chemical cleaning, the company states.

Another fixture designed to address hygiene is the IC Sink & Faucet System from American Standard Brands, Piscataway, N.J. It is designed to reduce splashing when a patient, doctor or nurse is washing his or her hands, which can transmit germs in a hospital room.

“The sink has a sloping back and an offset drain to prevent the water from splashing when it hits a horizontal surface,” says Tony D’Amato, product marketing manager for commercial fittings. “The drain is designed with a sealed overflow to eliminate an area for water to set and stagnate. Also, a permanent antimicrobial surface inhibits the growth of stain- and odor-causing bacteria, mold and mildew.” The system also features a hands-free faucet with a laminar flow restrictor in the spout base to prevent air from mixing with the water, and a plain spout end to eliminate areas where minerals and debris can build up and allow germs to grow.

Taking a different tack, AcornVac Inc., Chino, Calif., manufactures a vacuum plumbing system that eliminates flush overspray and mist that can contribute to the spread of bacteria. “Recent scientific evidence suggests that the plume created by gravity toilets can become airborne and cause additional infection control concerns. AcornVac toilets eliminate this plume, thus preventing the migration of germs and disease from the toilet bowl into the surrounding atmosphere,” says Tom Zinn, engineering director.

The system also allows plumbing renovation without the need to route waste lines with a continuous slope. As a result, existing real estate with limited drainage easily can be converted to address the needs of health care facilities, which typically have significant drainage requirements. “Because the AcornVac drainage system maintains piping under a continuous negative pressure, it virtually eliminates potential for the spread of infection due to leaking pipes or fittings. The system also provides an opportunity for easy decontamination of the waste stream before it is released to the public sewer system,” Zinn adds.

Another equipment trend in the battle against infection and cross-contamination is touchless fixtures such as sensor-operated faucets, flush valves, soap dispensers, hand dryers and bedpan washers, according to Will Haas, product manager, Bradley Corp., Menomonee Falls, Wis. Hands-free fixtures minimize contact with germs on surfaces such as doorknobs and countertops.

“These fixtures also cut down on maintenance time spent refilling paper towel dispensers, emptying waste bins, refilling soap dispensers, and cleaning and fixing broken faucet handles. Another trend is that hand-washing fixtures have evolved into very clean, streamlined shapes that evoke a modern and sophisticated sensibility,” Haas says.

However, it can be cost-prohibitive to install sensor-operated faucets in every patient room or doctor’s lounge, according to Sarah Lindegarde, senior product manager, Moen Commercial, North Olmsted, Ohio. “That’s why Moen Commercial offers a specialty line of faucets, M•Dura heavy-duty collection, to fit within a facility’s operating budget. The faucets include a smooth-handle design, without gaps or crevices, which makes them easy to clean.” The line also includes a bedpan washer.

Similarly, there is a shift away from sensor-operated faucets in certain areas of the hospital back to mechanical-operated faucets, according to Elkay’s Israelson. “Today we see more surgeons looking for a constant, uninterrupted flow of water when scrubbing up. The scrub process takes several minutes and most sensor faucets have a time-out feature that causes the units to turn off during washing. Also, surgeons want the water temperature to remain constant. Sensor faucets can have different temps depending on the type of temperature valve being used,” he notes.

Water savers

Water conservation is another major focus in plumbing fixture and fitting development, according to vendors that supply the nation’s hospitals. Water-conserving fixtures such as high-efficiency toilets use less water to flush waste while dual-flush toilets conserve water by using different amounts of water depending on flushing needs. Most models use 1.6 gallons per flush for solid waste and 0.8 gallons for liquid waste.

“For even greater water savings, ultra-low-flow toilets and waterless urinals may be used, while sensor-activated flush meters can help to control water use at peak times,” says Bradley’s Haas. “Tankless water heaters concealed within the pedestal of lavatory systems are another way to increase efficiency. Tankless units heat only the amount of water needed for each use, which cuts down on electricity usage by not heating an entire hot water tank for restrooms.”

Rada, a Kohler company based in Kohler, Wis., features a line of digital thermostatic faucets and showers that combine water conservation and safety, says Tim Schroeder, sales engineer. “Circulating temperatures, water velocities and water age are key factors in maintaining a safe condition in a hospital plumbing system,” he explains. “At low consumption, the velocity is low and temperatures throughout the system can fall out of recommended ranges. Low consumption can cause water to remain in the system, which allows the residual disinfectant to dissipate.”

The Rada system allows hospitals to maintain low usage during normal operations. It is possible to customize the schedule, flow rate and duration to the specific building design and usage pattern, which allows for high velocities, using just enough water per application. “By integrating the thermostatic control into the faucet, we eliminate the need for a separate ASSE International 1070 or 1016 device, allowing full-circulation temperatures to be delivered to the end-use fitting,” Schroeder explains.

Taken further, Vic Hines, senior field technical services representative, Charlotte (N.C.) Pipe and Foundry Co., says, “Depending on the budgets, we are starting to see some health care facilities using rainwater or treated gray water for non-potable water uses — everything from irrigation to cooling tower water make-up to water for flushing toilets and urinals.” Charlotte Pipe offers ReUze, a pipe designed for non-potable water that meets most local codes for pipe color and required markings, he notes.

Fostering accessibility

Designing barrier-free and bariatric fixtures is another goal of plumbing equipment manufacturers. Achieving minimum requirements of the 2010 Americans with Disabilities Act (ADA) Standards for Accessible Design is the key. Common issues include toilets located too far from the wall, grab bars placed in areas that are hard to reach and deep sinks with minimal knee space underneath the basin.

Bradley Corp. recently introduced the HS-Series Terreon Undermount Basins, multipurpose plumbing fixtures that achieve a high-design aesthetic in health care settings. The all-inclusive undermount basins are ADA-compliant and feature a clean, flat-bottom design for general hand washing or multipurpose use. They are constructed with durable, nonporous Terreon solid-surface material, so the basins are repairable to their original finish and do not harbor bacteria.

Flexible bathroom equipment is another growing trend that aids accessibility. “Many hospitals are standardizing on single-patient rooms, including rooms that can be adapted to meet the needs of each specific patient. Thus, adaptable bathroom equipment is becoming more of an attractive solution,” says Gary David Nowitz, president, Pressalit Care North America, East Dennis, Mass. “For example, using height-adjustable mounting systems, a bathroom might first be customized to handle an orthopedic patient, and then quickly reconfigured to handle the next patient who might be wheelchair-bound.”

Pressalit recently introduced the Matrix sink, which can be wall-mounted in a fixed height or mounted on a wall track. This enables the user to reposition the sink vertically and laterally. “This is especially important to meet postoperative needs of the elderly or people with physical disabilities,” says Nowitz. “Secondly, it has molded-in grasping handles along the front and sides. This is helpful for people with arthritis, who have balance problems or who are unsteady on their feet after an operation.”

Designing a restroom to meet minimum ADA standards doesn’t take into consideration positioning dispensers, trash receptacles and supply tables to allow space necessary for obese patients. Recessed dispensers and receptacles can minimize the footprint in these areas. Adding touchless temperature controls with high-contrast graphics and visual feedback to faucets, as well as ADA-compliant controls on showers and slide bars, can improve accessibility and safety.

Durable duty

Finally, manufacturers have unveiled a number of plumbing fixtures and fittings that offer improvements in durability.

Among them is the M•Power sensor- operated faucets from Moen Commercial featuring a sentinel flow option that purges the waterway 24 hours from the last use, and a cleaning mode that enables temporary sensor deactivation for cleaning and maintenance. Also, laminar-flow kits are available for increased sanitary protection and an optional temperature mixing lever allows facilities to customize the flowing water temperature.

Charlotte Pipe and Foundry Co. produces a CPVC laboratory waste product called ChemDrain that is widely used in hospitals. It provides a corrosion-resistant system with high-temperature handling capability, along with an easy installation method. “Hospital maintenance and facilities personnel like working with the ChemDrain system, which requires only common tools and pipe fitter skills to install,” says Hines.

Plenty of options

As these technological innovations demonstrate, health care facilities managers have plenty of options to choose from when it comes to selecting and implementing plumbing fixtures and fittings, and even more to look for in the years ahead.

Neal Lorenzi is a freelance health care writer based in Mundelein, Ill.

| Maintaining controlThe digital thermostatic technology used in this faucet offers advanced flow control combined with precise temperature control and bacteria resistance. |

| Setting limitsThe heavy-duty M•Dura Bedpan Washer is built to withstand the most demanding health care environments and designed to limit the spread of damaging bacteria in patient rooms. |

| Falling awayThe IC hand-washing sink and faucet system minimizes splashing by allowing the water stream to fall gently on the deeply sloped back wall of the hand-washing sink and away from the grid drain. |

| Surface safetyThe EcoVantage with SilverShield antimicrobial technology features a permanent antimicrobial glazed ceramic plumbing surface. |

| Clearing the airVacuum flush toilets, which come in wall- or floor-mounted, bariatric and ADA-compliant models, provide a more sanitary environment by eliminating flush plumes. |

| Extra protectionThis lavatory undermount sink is made with CuVerro antimicrobial copper for added infection protection. |

| Nowhere to hideSolid-surface material used in the HS-Series Terreon Undermount Basins features smooth, seamless, nonporous and easy-to-clean finishes that do not harbor bacterial growth. |

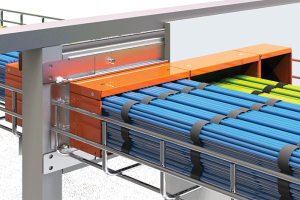

| Durable designChemDrain CPVC pipe and fittings are designed for chemical waste drain systems and offer a safe, durable, easy-to-install alternative. |