Strong foundation

Project Overview

- Project Name: St. Anthony Hospital

- Location: Lakewood, Colo.

- Floor area: 670,000 square feet

- Number of floors: 8

- Number of beds: 222

- Project cost: $640 million

- Construction cost: $233 million

- Groundbreaking date: September 2008

- Opening date: May 2011

Project Team

View "St. Anthony Hospital | Lakewood, Colo." Gallery

- Owner: St. Anthony Hospital/Centura Health

- Architect and Interior Designer: Earl Swensson Associates Inc.

- General Contractor: GE Johnson Construction Co.

- Furniture Specification: Gallun Snow

- MEP Engineering: Cator Ruma & Associates Co.

- Structural Engineering: Structural Design Group

- Civil Engineering: S.A. Miro Inc.

- Medical Equipment Planning: Mitchell Associates

- Food Service Design: Inman Foodservices Group

- Landscaping: studioINSITE

Information provided by Earl Swensson Associates Inc.

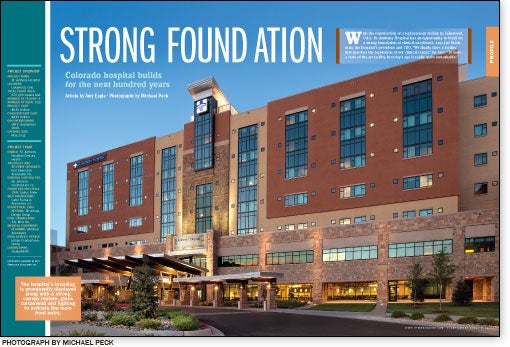

With the construction of a replacement facility in Lakewood, Colo., St. Anthony Hospital has an opportunity to build on a strong foundation of clinical excellence, says Jeff Brickman, the hospital's president and CEO. "We finally have a facility that matches the reputation of our clinical teams," he says. "To have a state-of-the-art facility in today's age is really quite remarkable."

Timeless design

The replacement facility is designed to provide a safe, comfortable environment for patients and staff and to operate efficiently with long-term appeal.

The prior St. Anthony facility opened in 1892. The designers of the replacement facility were mindful this building could be a 100-year-plus investment by the hospital. "We wanted it to be new and fresh and vibrant, but we wanted it to be timeless," says Sam W. Burnette, AIA, EDAC, senior designer/principal for architect and interior design firm Earl Swensson Associates Inc. (ESa), Nashville, Tenn.

The hospital's exterior features a stone material complementary to the indigenous stone of the Colorado Front Range, where the hospital is located. The stone material, which is meant to be a permanent part of the building's image, is installed primarily at the pedestrian level and main entrances. It is combined on the exterior with a stucco product, for economy. Generous amounts of glass bring light and views to the public areas of the hospital. Bands of curtainwall emphasize the vertical proportions of the building, especially where patient rooms are located. The use of glass is limited on the southern and western exposures, to reduce energy costs.

The architects took advantage of a nearly 30-foot slope on the hospital site to create three levels with direct outdoor access. Loading dock entrances are located at the lowest (or "garden") level, which houses primary support services. St. Anthony Hospital's main lobby and emergency department entrances are on the first floor. At the highest corner of the site is the entrance to OrthoColorado Hospital, an orthopedic specialty hospital ESa designed as Phase 1 of the replacement hospital project.

Distinctive interiors

Clean lines and forms lend a more contemporary, urban feel to the interior of St. Anthony Hospital, with natural stone products and wood tones referencing the nearby Rocky Mountains, says Christie M. McCullough, IIDA, ASID, EDAC, interior designer, ESa.

All of these elements can be seen in the design of sleek gas fireplaces located in the hospital lobby. "These fireplaces are just people magnets," says Burnette, who has noticed that seats near the fireplaces fill faster than other lobby seating areas.

Statues of Jesus and St. Anthony that were relocated from the previous hospital are placed in prominent areas of the public spaces, to honor the legacy of the religious institution. Stained glass from the former hospital chapel is featured in the new chapel. Bringing elements of the old campus to the new campus "was very important to all the key stakeholders," says Ryan Tobin, administrator of operations, St. Anthony Hospital.

For the hospital's interior materials and finishes, the designers considered a hierarchy of building elements, says Ken L. Bowman, IIDA, ASID, LEED AP ID+C, EDAC, interior designer/interior design manager, ESa. Major elements, like the fireplaces, feature natural-looking products with a longer expected life cycle. A bolder, brighter approach was taken with design elements that will be replaced more readily, like paint and vinyl flooring. The hospital's fresh take on color in the patient units was especially fun to work with, says Stephanie L. Wennerlund, IIDA, interior designer, ESa. "We almost couldn't get it bright enough for them," she says.

'Inside-out' design

Tim Keenan, administrative director of support services, St. Anthony Hospital, says, "Typically, buildings are built from the outside in," with the exterior footprint taking precedence in the design. For St. Anthony, the team started with the patient room and designed the floor plan and support services outward from there, for greater efficiency, he says.

To reduce walking distances, the patient units are laid out in a racetrack configuration, with support spaces in the middle. "The goal is to shave two or three miles off each nurse's shift," says Burnette. Pre- and post-occupancy testing will determine how walking distances compare with those at the previous facility.

Small oasis rooms on the medical units give caregivers quiet spaces to decompress or even receive a massage during a stressful shift. A thoughtful work environment is intended to improve staff retention.

The patient rooms contain a number of features for the comfort and safety of patients and staff, including grab bars that lead from the bed to the bathroom, patient lifts and observation windows with integrated miniblinds that can be opened for patient visibility or closed for patient privacy. Double doors at each patient room facilitate patient transport.

Computed tomography and magnetic resonance imaging equipment are located immediately adjacent to the surgical center on the facility's second floor. The hospital's floor system and structural frame are designed to handle the additional load of this equipment and to prevent building vibration from interfering with sensitive procedures.

The hospital's 76-bed intensive care unit also is located on the second floor, near the surgical center, catheterization laboratory and interventional radiology procedural platform.

Community embrace

Since the replacement facility opened, patient satisfaction scores have risen from the 35th percentile to the 88th percentile and the hospital's turnover rate is down, Tobin reports. "The Lakewood community has really embraced this hospital," he says. "We hear all the time they've never seen a hospital like this."

Amy Eagle is a freelance writer based in Homewood, Ill., and a regular contributor to Health Facilities Management.

Sidebar - Facility's building automation system provides increased operational efficiency

Sidebar - Trauma center designed for quick emergency response

Sidebar - SPEC SHEET