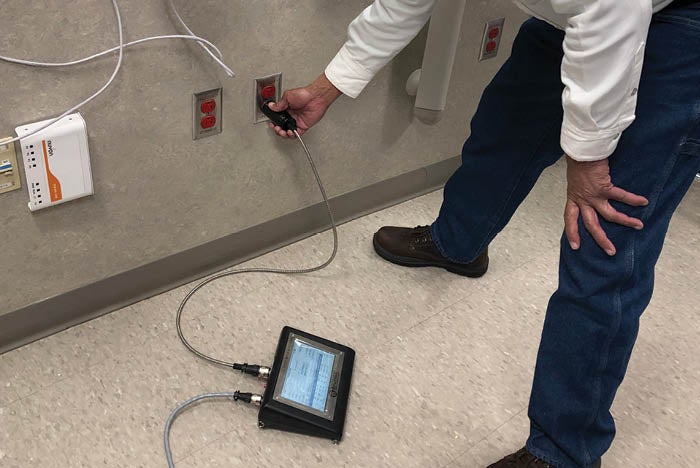

Receptacle testing in patient areas

Michael S. Scroggins Sr., LME, electrical supervisor at Children’s Hospital of Philadelphia, testing receptacles with a digital analyzer.

Image courtesy of Children’s Hospital of Philadelphia

Ensuring reliable receptacles in the patient care environment is an important part of keeping patients, families and staff safe.

To ensure proper operation of devices during emergency situations and to enhance electrical safety, a policy should be designed to promote a safe and healthy work environment for employees working with any electric appliances or equipment and to comply with Occupational Safety and Health Administration Standard 29 CFR 1910 Subpart S.

By the book

The 2011 edition of the National Fire Protection Association’s NFPA 70®, National Electrical Code®, Article 517, defines requirements for all equipment that will supply electrical power within patient care areas. 517.18(B) requires hospital-grade receptacles in patient care areas. This is a straightforward requirement to which all health care facilities managers are accustomed.

Many facilities managers have standardized that all receptacles throughout health care inpatient, ambulatory and outpatient spaces are hospital grade-type for higher quality outlets throughout these buildings (not only inpatient care areas) and to keep maintenance and testing simplified.

For receptacle testing, the 2012 edition of NFPA 99, Health Care Facilities Code, is the standard required by the Centers for Medicare & Medicaid Services (CMS), and the handbook expands on the standard with supplemental information:

- Section 6.3.4.1.1 states that hospital-grade receptacles must be tested after initial installation, replacement or servicing of the device.

- Section 6.3.4.1.3 states that receptacles not listed as hospital grade, at patient bed locations, and in locations where deep sedation or general anesthesia is administered must be tested at intervals not exceeding 12 months.

- Section 6.3.4.1.2 states that additional testing of receptacles (including hospital-grade receptacles) in patient care rooms shall be performed at intervals defined by documented performance data. Therefore, facilities managers have to test hospital-grade receptacles at a frequency determined by the health care organization based on information such as historical data or manufacturer’s recommendation(s). This applies to new and existing occupancies and is not limited to just hospitals.

NFPA 99-2012, 6.3.3.2, outlines the requirements for receptacle testing in patient care spaces, summarized as:

- The physical integrity of each receptacle shall be confirmed by visual inspection.

- The continuity of the grounding circuit in each electrical receptacle shall be verified.

- The correct polarity of the hot and neutral connections in each electrical receptacle shall be confirmed.

- The retention force of the grounding blade of each electrical receptacle (except locking-type receptacles) shall be not less than 115 grams (4 ounces).

The NFPA 99-2012 handbook also explains that a low-tension value obtained during testing means the ground pin of an appliance will not make good contact with the grounding blade of the receptacle. This is important, as this indicates the low-impedance path to ground is compromised for the green ground wire of the appliance plugged into the outlet.

NFPA 70-2011, Article 517.18(C), requires tamper-resistant receptacles in pediatric locations of health care facilities (e.g., hospitals, physician offices and therapy areas), including patient rooms, bathrooms, playrooms, activity rooms and patient care areas of designated pediatric locations. As an option, the receptacle may use a listed tamper-resistant cover. The listing would have to be from an independent testing laboratory, such as UL.

More recent editions of NFPA 99 and 70 have expanded on this requirement: “Receptacles that are located within patient rooms, bathrooms, playrooms, and activity rooms of pediatric units or spaces with similar risk as determined by the health care facility’s governing body by conducting a risk assessment, other than infant nurseries, shall be listed and identified as ‘tamper resistant’ or shall employ a listed tamper-resistant cover.” Many facilities have decided to place these in all waiting areas since children are likely to be there at times.

Tamper-resistant receptacles are designed with spring-loaded receptacle cover plates that close off the receptacle openings, or slots.

When equal pressure is simultaneously applied to both sides, the receptacle cover plates open, allowing a standard plug to make contact with the receptacle contact points. Without this synchronized pressure, the cover plates remain closed, preventing the insertion of foreign objects.

It shall be noted that tamper-resistant receptacles listed by UL have the words “tamper resistant” or the letters “TR” on the device.

NFPA 70-2011, Article 517.17 (D), requires the ground-fault circuit interrupter (GFCI) receptacles to be tested upon the initial installation, but there is nothing mentioned about annual or monthly testing requirements. This leads us to understanding the manufacturer’s recommendations.

Manufacturer’s recommendations

CMS condition of participation CFR §482.41 (c)(2) interpretive guidelines states that hospitals must follow the manufacturer’s recommendations for maintenance activities, or they must comply with the alternate equipment management (AEM) program.

GFCI outlets are to be inspected and tested monthly in accordance with manufacturer’s recommendations, which are based on UL 943. In occupied inpatient spaces, this becomes extremely challenging. Additionally challenging are the outpatient facilities entailing millions of square feet and sprawling locations. The installation/owner’s manual information received with every GFCI outlet includes the manufacturer’s recommendations.

GFCI self-testing receptacle testing recommendations include:

Manual test. Press the “test” button (then “reset” button) every month to assure proper operation.

Automatic self-test. Self-testing diagnostic is automatically performing a self-test of the electronics every minute. The manual test should be performed every month to assure proper mechanical operation.

If there is a failure during the manual test or the automatic self-test, the red LED will flash indicating that the receptacle has lost its GFCI protection. If this occurs, the GFCI should be replaced immediately.

Conducting a safety risk assessment is important to evaluate and validate the approach to ground-fault receptacle safety. Monthly inspection of GFCI receptacles is challenging, as many areas are inaccessible without disrupting patients and families. Inventories will need to be captured, documented and adjusted.

Testing procedures

One of the best ways to determine how to approach this task is to train and review procedures with facilities staff.

In discussions with facilities managers, the four key factors to test receptacles in patient areas are for impedance, tension, polarity and grounding. The preferred testing device to test receptacles is an advanced model with a digital interface touchscreen to display test results immediately and to generate the required reports.

If a manager does not have an advanced model, below are the tools and methods to accomplish the required testing (this data will need to be captured in a standardized form and recorded):

Continuity test. The continuity test ensures that the equipment grounding conductor is electrically continuous. Facilities managers should perform this test on all cord sets, receptacles that are not part of a building or structure’s permanent wiring, and cord- and plug-connected equipment required to be grounded. This test can be accomplished with various test equipment. Examples of test equipment include a voltage and continuity tester, analog multimeter and digital multimeter.

Terminal connection test. The terminal connection test ensures that the equipment grounding conductor is connected to its proper terminal at receptacles and cord plugs. Facilities managers should perform this test with the same equipment used in the first test; or, for receptacles, they should use receptacle testers.

Smart receptacle design

Knowing the challenges of front-line facilities staff in conducting preventive maintenance, responding to everyday issues and dealing with emergencies, facilities managers look to strategies in new construction and renovations to help alleviate some of the burden.

The facilities design standards should require the electrical contractors to provide the required NFPA 99 testing documents with contract closeout, and on large-scale projects commissioning agents also should submit third party test reports. Creating and/or updating a hospital’s facilities design guidelines with lessons learned on a continual basis is recommended.

All new construction and renovation projects should include within the electrical specifications the requirement for the electrical contractor to provide the NFPA 99-required receptacle testing reports at contract closeout. Having a commissioning agent follow through on collecting these reports and conducting third-party testing is advised.

Facilities managers should avoid quad-mounted GFCI outlets because the standard quad box may not be sufficient to adequately house two quad GFCIs and the wiring, leading to failures and branch circuit breaker tripping.

What are some possible ways around a quad GFCI in a 10-foot by 12-foot exam/treatment room with a sink and where power is needed within 6 feet of a sink? Some alternatives to consider include:

- Utilizing a snap-connect GFCI quad because these provide for connections in the backbox without crowding the wiring in the backbox.

- Utilize one GFCI duplex and feed through to protect the adjacent duplex.

In general, the snap connect-type wiring devices have stood the test of time since they first came on the market, and there can be advantages in health care spaces to specifying these types for new construction and renovations.

When it comes to inpatient rooms, which are difficult to access for maintenance, consider the following:

- Utilizing GFCI circuit breakers to protect outlets near sinks in inpatient rooms. It is easier to test circuit breakers in electrical closets monthly than to access inpatient rooms for inspection of GFCI outlets every month. Careful consideration of the wiring of receptacles served by these breakers to only include receptacles within 6 feet of sinks would be best. This way, normal hospital-grade receptacles, with proper GFCI protection labeling, could be used and the aforementioned testing could be performed.

- Refreshing rooms once a year allows maintenance to occur annually, which greatly aids in patient and family satisfaction.

When reviewing power device design layouts, facilities managers should encourage the use of quadruplex devices when needed to avoid power strips being inadvertently added later when spaces are occupied. Power device layouts should be designed to meet current and future needs without the need for power strips.

On power strips

Power strips shall be UL listed and hospital grade. They must be adequate for the number and types of devices, not overloaded. They must not be daisy chained (interconnected with other power strips) and must not present a trip hazard.

Power strips within the patient care vicinity (defined as spaces extending 6 feet beyond normal location of the patient and extending 7 feet, 6 inches vertically above the floor) have the following requirements:

- Shall only power movable patient care medical equipment.

- Are permanently attached to patient care medical equipment assemblies.

- Must be listed as UL 1363A or UL 60601-1.

- Shall not be used for nonpatient care-related electric equipment.

- Should be regularly verified and documented through ongoing preventive maintenance.

- Shall not be overloaded (the sum of the ampacity of all equipment connected to the receptacle shall not exceed 75% of the ampacity of the flexible cord supplying the receptacles).

Power strips outside the patient care vicinity but in the patient care room have the following requirements:

- Those that power patient care-related electrical equipment must be listed as UL 1363A or UL 60601-1.

- Those that power nonpatient care-related electric equipment must be listed as UL 1363.

Finally, power strips in nonpatient care areas (e.g., offices) must be UL listed and hospital grade.

Frank D. Rudilosso, PE, CHSP, is director of facilities organizational readiness at NewYork-Presbyterian Hospital, New York City, and Mary Alcaraz, PE, LC, CEM, LEED AP, is senior project manager at Children’s Hospital of Philadelphia. They can be reached at frr9035@nyp.org and alcarazm@email.chop.edu, respectively.