Tips on enterprise asset management

By integrating data analytics and business intelligence systems into an EAM system, organizations can improve their decision-making processes.

Image by Getty Images

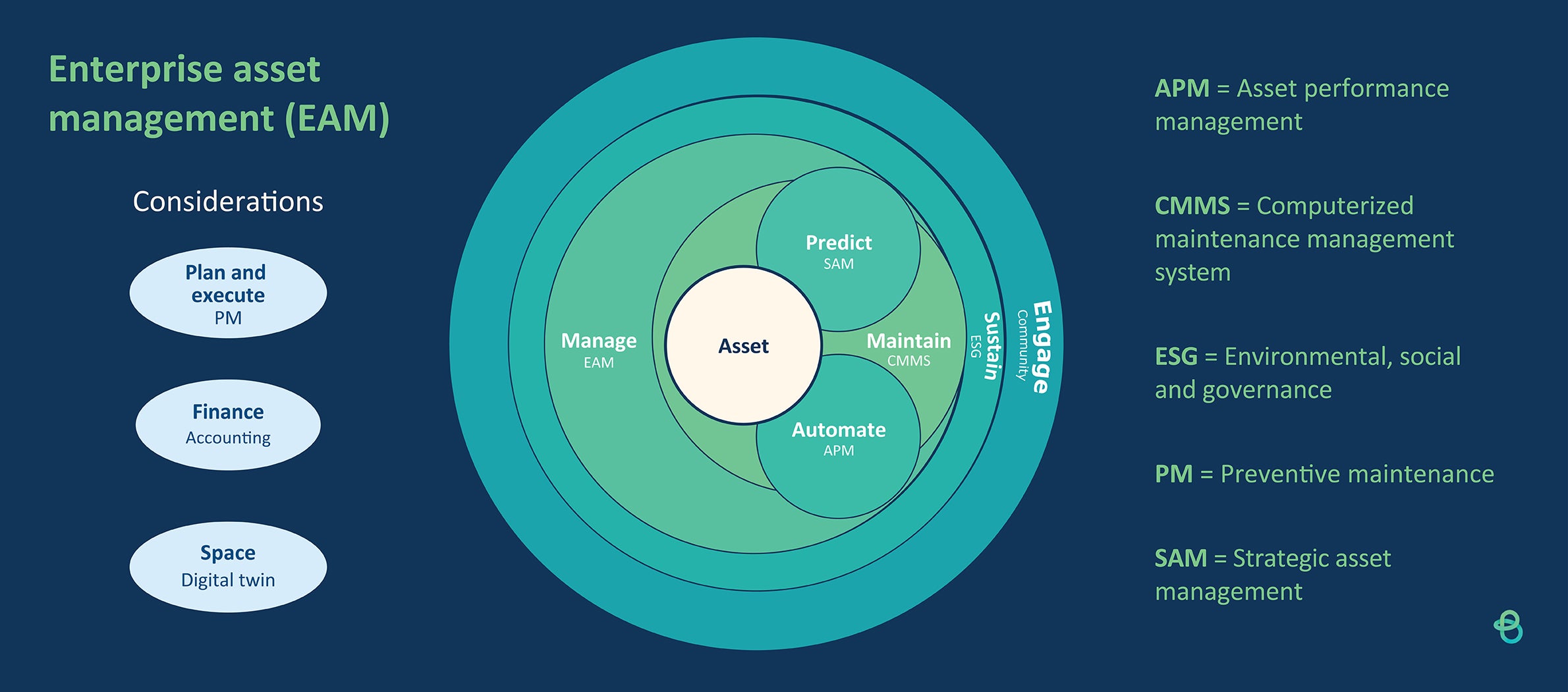

The world of technology and data is an alphabet soup of acronyms and definitions. Among the potentially most useful of these for health facilities professionals is the concept of enterprise asset management (EAM) and the importance of strategic asset management (SAM) within the EAM system.

EAM is the systematic and strategic management of an organization’s assets throughout their entire life cycles, including planning, design, acquisition, installation, maintenance and disposal. Assets include equipment, machinery, vehicles, buildings, software, patents and intellectual property. EAM is a critical aspect of modern business operations, as it enables organizations to optimize asset performance, reduce costs and improve overall operational efficiency.

EAM activities

EAM encompasses various activities, including asset tracking, maintenance planning and scheduling, inventory management, condition monitoring and performance analysis. It also involves integrating asset management practices with other business processes such as finance, procurement and operations. The ecosystem of an EAM can be expansive, yet the data and analysis from one’s current systems become powerful. Some of these systems are:

- Enterprise resource planning (ERP). ERP is a software solution that helps organizations manage their business processes, including finance, human resources and procurement.

- Geographic information system (GIS). GIS is a software system that helps organizations manage geographic information and spatial data.

- Energy management system (EMS). This is a software system that helps organizations manage energy consumption and reduce energy costs. By integrating an EMS into an EAM system, organizations can optimize their energy usage, reduce energy costs and improve sustainability.

- Data analytics and business intelligence systems. Data analytics and business intelligence systems are software solutions that help organizations analyze and interpret data to make informed decisions. By integrating data analytics and business intelligence systems into an EAM system, organizations can improve their decision-making processes, optimize asset management strategies and reduce costs.

- Internet of Things (IoT). IoT systems are connected devices that can communicate with each other and transmit data. By integrating IoT systems into an EAM system, organizations can improve their asset monitoring, optimize their maintenance operations and reduce asset downtime.

- Computerized maintenance management system (CMMS). This is a software system that helps organizations plan, schedule and track maintenance activities. The foundation of any EAM system is the assets. Often referred to as a “work order management” system, a modern CMMS can utilize machine learning, artificial intelligence and IoT as well as other technologies to provide advanced data, key performance indicators (KPIs) and analytics.

Key to this data is understanding work order types and workflows. The first delineation of work orders is between preventive maintenance (PM) and corrective maintenance (CM).

PM falls into four separate subsets. They include time-based maintenance, which is calendar-driven; run-based maintenance, which is based on how long the equipment has been utilized; condition-based maintenance, which is often predictive or health-related; and operator-based maintenance, which is generally performed by an operator as part of their responsibilities.

CM falls into three types. They include CM routine, which is planned and scheduled work resulting from PM; CM repair, which is generally a planned and scheduled repair on or investment in an asset; and CM reactive, which is unplanned and unscheduled work resulting from a failure. Identifying these work orders and workflows will better utilize the EAM, SAM and CMMS capabilities.

- Asset performance management (APM). APM is a software system that helps organizations manage their assets throughout their life cycles. It is a key component of a reliability-centered maintenance (RCM) program. APM, whether in the form of remote ultrasonic and temperature devices, or data from building automation, fire alarm, security or video systems, allows one to create RCM maintenance strategies to reduce failures and unplanned events. The American Society for Health Care Engineering (ASHE) has created a reference on RCM, which can be accessed through the “ASHE Resource” box below.

The outcome can be increased asset useful life, decreased deferred maintenance, reduced costs from planned versus reactive maintenance, and decreased project costs due to planning instead of addressing an emergency. Additional thought should be given to utilizing APM in commissioning, at least through the warranty period, to validate the performance of newly installed assets. The construction process offers further APM opportunities through integration from the project management; sustainability; environmental, social and governance; and financial systems to integrate with EAM and SAM tools.

By implementing effective EAM practices, organizations can ensure that their assets are available when needed, operating efficiently and delivering the expected results. EAM also helps organizations comply with regulatory requirements, manage risks associated with assets, and make informed decisions regarding asset investments, maintenance strategies and replacement schedules.

The role of SAM

SAM is another key component of EAM. It involves aligning asset management practices with an organization’s strategic objectives. SAM goes beyond day-to-day asset maintenance and operations and focuses on the long-term planning and optimization of an organization’s asset portfolio. SAM requires organizations to understand their entire asset portfolio comprehensively. This involves conducting a thorough inventory of all assets; collecting data on their performance, condition and costs; and then analyzing the data to gain insights into asset utilization, efficiency and effectiveness. Organizations must identify critical assets, assess their value and risks, and prioritize maintenance and replacement based on strategic objectives.

Some key strategies include APM, asset life cycle management and asset risk management. Asset life cycle management involves managing assets throughout their entire life cycles, from acquisition to disposal. This includes defining asset acquisition policies, developing asset standards and specifications, evaluating and selecting vendors, negotiating contracts, managing warranties, and overseeing asset installation and commissioning. It also involves managing asset operations, maintenance and repairs; optimizing asset utilization; and planning for asset replacements or disposals based on business needs and strategic objectives.

APM requires organizations to monitor and analyze asset performance to identify opportunities for improvement. This involves collecting and analyzing data on asset performance metrics such as availability, reliability, maintainability and safety. Organizations can use advanced analytics techniques, such as predictive maintenance and condition-based monitoring, to identify asset performance trends, patterns and anomalies, and take proactive actions to optimize asset performance and reduce downtime. APM also involves setting performance targets, measuring performance against targets and continuously improving asset performance through data-driven decision-making.

Asset risk management involves identifying and managing risks associated with assets. This includes assessing risks associated with asset failures, safety hazards, environmental impacts, regulatory compliance and financial risks. Organizations must develop risk mitigation strategies, such as implementing PM programs.

SAM is a continuous process that requires ongoing organizational commitment. By implementing SAM, organizations can improve the value of their assets and achieve their strategic goals and objectives. SAM requires a cross-functional team of experts. The team should include finance, operations, maintenance, engineering and information technology representatives.

Several steps go into implementing SAM in any organization. The first step in SAM is to identify the organization’s strategic goals and objectives. Once the goals and objectives are known, the team can identify the assets needed to achieve those goals. The next step is to assess the current condition of the organization’s assets. This assessment should include an evaluation of the asset’s condition, expected useful life and replacement cost.

This is best accomplished through a well-scoped and defined facility condition assessment (FCA). Selecting the correct partner in conducting an FCA will be important to the success of the participation of the facility team’s subject matter experts and the information provided to the FCA teams.

Once the current condition of the assets is known, the team can begin to develop a plan for managing the assets. The plan should include a schedule for PM, a budget for repairs and replacements, and a process for disposing of obsolete assets. The final step is to implement the plan and monitor its progress. The team should regularly review the plan and adjust as needed.

SAM aims to optimize the value of an organization’s assets by ensuring they align with its strategic goals and objectives. SAM can help organizations reduce costs, improve efficiency, provide for short- and long-term planning strategies, and increase profitability through data-driven capital planning.

Capital planning provides organizations with a framework for evaluating the effectiveness of their asset management strategies and making informed decisions about future investments and asset management priorities. SAM plays a critical role in capital planning by providing a structured approach for allocating financial resources to acquire, maintain and upgrade assets in alignment with an organization’s strategic objectives. It helps organizations to make informed investment decisions, mitigate risks, ensure financial sustainability and monitor performance to optimize the value and performance of their assets throughout their life cycles.

When implementing a SAM plan, some key considerations include asset acquisition, which involves strategically allocating funds to acquire assets necessary to support the organization’s operations, growth and strategic objectives; asset maintenance and upgrades, which includes allocating funds for the ongoing maintenance, repair and upgrades of assets to ensure optimal performance and extend their useful lives; and risk management, which mitigates risks associated with assets. This includes identifying risks such as equipment failure, technological obsolescence, regulatory compliance and financial risks, and allocating funds for risk mitigation such as insurance, warranties or contingency reserves.

When considering an EAM or SAM, facilities professionals should consider whether they are ready for such a commitment organizationally. Practical steps to prepare an organization for an EAM or SAM deployment begin by evaluating the CMMS. The data and workflows required for an EAM or SAM should be verified and documented. As described earlier, preventive, planned and corrective work orders should have an implemented and documented workflow. All assets should be captured in the CMMS. The data should be complete for each asset, including installation dates, units of measurement and related quantities. Each asset should have a bar code, and asset data types, locations and buildings should be standardized for the organization. Each asset should be assigned a risk and condition score, and asset cost and replacement cost should be determined.

Once this information has been collected, an organization can use the data to determine and assign maintenance strategies. These strategies can range from “age in place” to any form of RCM and compliance-driven strategies. An organization will now have the fundamental data, workflows and processes to begin the deployment of either an EAM or SAM system. Because the work was done upfront, the organization can utilize the power of these KPIs, analytics and reporting functions to make solid business decisions with the highest confidence level. The organization’s leadership will appreciate data-driven, risk-based forecasts aligned with the organization’s strategies. As an unintentional consequence of this work performed, the existing CMMS and related systems will also begin to function and be utilized as designed. KPIs and reporting can now be accomplished.

A major role

There is little doubt that technology will play a major role in the maintenance and operations of future buildings. With the prospect of losing key institutional and skilled knowledge through attrition or the deficit of qualified, skilled tradespersons, there is much value in a connected world.

The health care organization’s leadership teams will be looking to have this information and insight to make the most informed and educated decisions based on data. Having data to justify staffing levels, specify equipment types, automate labor-intensive processes, increase employee and patient safety, and increase patient satisfaction are mutual benefits for any organization.

ASHE has numerous resources available through previous articles, published literature, a community of subject matter experts, conferences, consultants and vendors. Many health care organizations are sharing their success stories with accompanying resources.

Facilities professionals should identify the resources they need and reach out. ASHE members are there to support, advance and equip their peers and the entire field.

The role of RCM in an EAM system

Reliability-centered maintenance (RCM) plays a crucial role in enterprise asset management (EAM) by providing a systematic approach for analyzing and optimizing maintenance strategies. RCM enhances EAM systems through:

- Asset identification and prioritization. RCM can help identify and prioritize assets based on their criticality and impact on the organization’s operations. By analyzing the reliability of assets and their failure modes, RCM can determine which assets require more attention and resources in terms of maintenance efforts and which assets can be managed with less intensive maintenance activities.

- Maintenance strategy development. RCM helps identify the most appropriate maintenance tasks, frequencies and methods based on the asset’s reliability characteristics and the organization’s operational requirements. These maintenance strategies can then be integrated into the overall EAM system to ensure consistent and optimized asset management practices.

- Maintenance optimization. RCM can help optimize maintenance activities by eliminating unnecessary maintenance tasks and focusing on the most critical ones. This can result in improved asset performance, reduced downtime and lower maintenance costs. RCM can also aid in developing condition-based maintenance strategies, where maintenance activities are triggered based on the asset’s actual condition as opposed to a fixed schedule, leading to more efficient and effective maintenance practices.

- Root-cause analysis. By analyzing failure modes and their underlying causes, RCM can help identify and address the root causes rather than just treating the symptoms. This can lead to more sustainable and long-term solutions, reducing the recurrence of failures and improving overall asset reliability.

- Data-driven decision-making. RCM relies on a data-driven approach that can be integrated into an EAM system to provide a solid foundation for decision-making. By leveraging data on asset performance, maintenance history and reliability analysis, organizations can make informed decisions on asset management strategies, resource allocation and capital planning, leading to more effective asset management practices.

- Continuous improvement. By regularly reviewing and updating maintenance strategies based on new data and feedback, organizations can continuously optimize their asset management practices, improving asset performance, increasing reliability and reducing costs. This aligns with the principles of continuous improvement and optimization that are central to EAM.

About this article

This is one of a series of articles contributed by the American Society for Health Care Engineering’s Member Tools Task Force.

Scott Mason, CHOP, FRSPH, HCC, is senior manager of strategic asset management for professional services at Brightly, a Siemens company, in Cary, N.C. He can be contacted at scott.mason@brightlysoftware.com.