Ready for anything

Most hospitals have an emergency plan in place to protect them from disaster. Typically, though, these strategies have been pieced together one department at a time over many years and lack a crucial overview of the larger facility, its daily needs and its place in the community.

Most hospitals have an emergency plan in place to protect them from disaster. Typically, though, these strategies have been pieced together one department at a time over many years and lack a crucial overview of the larger facility, its daily needs and its place in the community.

As many recent disasters have revealed, these plans can leave hospitals vulnerable to outside factors that were not previously considered and to the looming cascade effect of the disaster itself. It is therefore important that every hospital have a holistic emergency master plan to defend its building, patients and staff members from both internal events, like fires and disruption to a piece of machinery, and external threats like terrorism, weather and epidemics.

This emergency master plan should begin with early involvement from the design team, the hospital staff, emergency responders and local utility providers, while adapting and exploiting the unique opportunities and synergies that often surface with change. These will help inform and employ the appropriate location of equipment, the right mix of reliability, redundancy and flexibility as well as a true understanding of the hospital's mission statement and goal.

|

| The emergency generator plant is one component of an effective emergency master plan. |

Developing the plan

The major considerations in developing an emergency preparedness master plan include the following:

Understanding the hospital. No two hospitals are exactly alike. Every hospital is defined by its culture and geographic location. Master plan considerations must take into account regional vulnerabilities, such as hurricanes in the Southeast, tornados in the Midwest or earthquakes in the West. Similarly, each hospital has its own unique business plan and goals. This is why it is important to interview hospital administrators to determine goals, current plans and any other information that will affect the final implementation of the emergency master plan.

Is the hospital building the community's safe haven in case of an emergency? Is the building in a flood zone? How many electrical lines are entering the building? Are the electrical lines overhead on poles or installed underground? Is the boiler room near a river that overflows occasionally? The answers to these questions can help the design engineer create a comprehensive technical report card that can be used as a springboard for the hospital's official emergency master plan.

Finally, utility incentives may help offset initial capital costs for new, efficient equipment to support the emergency master plan. A little investment of time into researching these incentives often pays off for the client and the campus.

Interactive early involvement. Collaborating from the start with the hospital's administration and staff is crucial to creating an accurate emergency master plan. A first important step in collecting a hospital's vital statistics is for the design team to visit the site, talk to the staff and interview the facilities personnel that interact with the public utilities. These early discussions help determine how reliable the current utilities have been and where reliability and communication can be improved.

For example, during the early involvement/master plan research at one 1.3-million-square-foot East Coast hospital, a hospital engineering firm found that although the electrical power was generally reliable, the hospital was still susceptible to electrical service interruptions because of how the utilities connected to the site, with little or no physical protection. Because this was discovered early during the master planning process, the team was able to relocate the power to a remote location on campus and distribute it accordingly.

The design team should always work with the local utility and hospital representatives when developing the master plan. Then, prior to finalizing and implementing it, meet again to let them know what issues were noted and incorporated. In a state of emergency, it will be important that the community, the utility company and all of the emergency responders communicate effectively. When modeled early on, these open lines of communication will naturally be replicated.

Opportunities and synergies. When writing a master plan to accompany a hospital expansion or renovation, a number of opportunities and synergies will naturally arise. Whether it's moving the central utility plant because of existing site constraints or building a new high-rise patient tower, a diligent design team always looks for opportunities to improve the campus infrastructure's flexibility and reliability.

Many times the improvements are incremental and not wholesale replacements, so keeping a scorecard on how the different portions of the infrastructure rank as far as reliability, flexibility, capacity and redundancy will help remind the project team where efforts might be best spent.

In another example, a hospital's central plant was resized and relocated to accommodate a new 280,000-square-foot patient building at the site of the previous plant. Using high-performance energy modeling, the engineering firm found that the utility plant would benefit from new energy-efficient equipment and improved building elements like windows and walls.

These improvements, coupled with creative and innovative engineering, resulted in 15 percent reduced energy consumption, as well as an expected similar reduction in annual operating and maintenance costs. This opportunity improved the reliability of the existing infrastructure, increased overall campus efficiency and met the project goals.

Finally, during the creation of the hospital's master plan, it's important for the design team to investigate the potential opportunities and synergies for equipment or infrastructure upgrades that can be accomplished for little or no extra cost. Engineering firms should work closely with the hospital's facilities personnel to understand how they operate their plant equipment so that the planning is in concert with how the campus is operated.

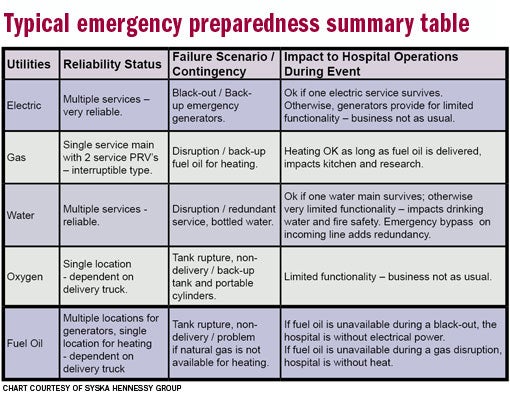

|

| Contingency planning for all utilities is crucial. |

Reliability, redundancy and flexibility. Reliability must be innate and intrinsic to any emergency master plan. It's known that electrical loads rise during an emergency because of the added loads of emergency signaling, the deployment of emergency equipment and other uses. Therefore, back-up generators should be designed in an incremental and expandable fashion and reviewed so that no single piece of equipment is solely relied upon.

Facilities professionals should build flexibility into the system by leaving additional space for smaller generators to be added as needed. This will require pre-planning for space considerations, not only for the generator but also for the paralleling and distribution gear. Planning for expansion of the generator plant should also include the mechanical side (e.g. generator combustion air, exhaust air, fuel storage and heat rejection) so that later additions to capacity are done with little interruption and cost.

As the hospital grows, it should continue investing at a pace that is comfortable for the facility. The engineering firm should provide the hospital with enough information to make a technically and economically sound decision at a later date.

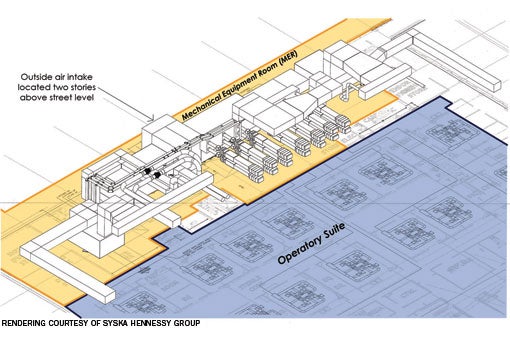

Equipment location. Air changes within a hospital are critical on a daily basis and during an emergency. A thorough master plan should include specifying the air intakes in areas that are inaccessible to the public. Securing the mechanical equipment from any outside threat is crucial.

Best practice dictates that equipment rooms and oxygen and oil storage should be located on each floor in lieu of large reserves at the top or bottom of a building. For this reason, it is crucial that the location of each piece of critical mechanical equipment and the storage vessel be assessed during the master planning process. It is also pertinent to review the hospital's location and its proximity to additional utilities and resources.

It is important for the project team to continue to ask the important questions: How many days of storage does the hospital need to have? How many days until another delivery would be possible? What happens if additional resources can't make it to the hospital for six or more days?

Additionally, do not place air intakes in areas accessible to the public. Treat mechanical equipment rooms and hazardous storage areas as critical locations. Develop a plan to generate up to three days of electricity in the event of a disaster through either storage or guaranteed fuel delivery.

|

| Strategic placement of outside air intake well is essential. |

Making it real

The final step in writing the emergency master plan is to make it real. Finish up with a high-level assessment of the existing campus so that opportunities to improve current reliability can be identified and make new things even better by marrying old and new.

Ask "How can the current load be reduced?" and then design the new and existing systems to react accordingly. Plan and implement for the use of switches and valves to be included in order to vary the use of equipment to extend its life span. For example, if the hospital has 20 air handling units, 15 of which are for comfort and five of which are dedicated to the intensive care and surgery units, the electrical equipment should be dressed with transfer switches and the piped utilities should be included with a smart distribution system.

Design and build systems and infrastructure with interconnections so that backup systems are already in place. Running additional pipe or conduit from Building A to Building B may increase the budget now, but when there's a disaster those backup measures will be a savior.

Crucial to survival

A hospital is tied to and dependent on the outside world for its crucial resources, including electrical service, water supply, natural gas and the disposal of waste. When these resources are no longer available, the hospital's emergency master plan will be crucial to the survival of its building, patients and staff.

Once the hospital's goals have been understood; all project team members have worked together from early on in the master planning process; opportunities and synergies have been realized; reliability, redundancy and flexibility have been championed; equipment has been placed in the right locations; and the emergency master plan has been staged, the hospital will be armed and ready for what lies ahead.

Joshua D. Zweback, P.E., LEED AP, is an engineer at Syska Hennessy Group, New York City.