Mock surveys may help construction budgets

Cost overruns and schedule delays are always a potential outcome on construction projects, especially when building the sometimes large and complex facilities that many health care organizations require. But as seen year after year in the annual Hospital Construction Survey, conducted by the American Society for Health Care Engineering’s Health Facilities Management magazine, the majority of health care construction projects tend to fall into the “on/under budget and on/ahead of schedule” category.

From year to year dating back to 2006, Hospital Construction Survey respondents reported that the largest percentage of their construction projects have been both on budget and on schedule or better. For instance, in 2012, an average of 68% of construction projects were on budget and on schedule, compared to 12% of projects that were over budget and behind schedule in that same year. The middle 20% for that year were either on budget or on schedule but not both.

Those numbers have shifted year to year. In 2024, for example, as the construction industry grappled with (and still does) the unholy trinity of inflation, labor shortages and supply-chain choke holds, respondents reported that 43% of recently completed projects hit that perfect target, compared to 23% of projects that were reported as being behind schedule and surpassing their budget. In 2025, those numbers sit at 47% and 24% for all respondents, respectively, with 29% of projects hitting one mark or the other but not both.

Each year, the Hospital Construction Survey asks about several longitudinal factors, such as the above-mentioned key performance indicators (KPIs), planned projects and anticipated construction budgets. But each survey also zeroes in on one angle that influences the delivery of health care construction projects, such as building for resiliency or sustainability. This year’s survey, which was reported in the March/April issue, focused on Day 1 operational and survey readiness.

Sometimes these special focuses can highlight interesting correlations with our longitudinal data. The 2025 survey posed a question about the internal policies and practices health care organizations implement during the planning, design and construction process to ensure facilities are operational and survey ready on Day 1 of opening. There were many multiple-choice options to choose from, including the top three of conducting building systems and equipment training prior to move-in (79%), conducting staff building tours (63%) and performing emergency management drills and exercises (57%). Fourth on the list was conducting mock surveys prior to project turnover to find and resolve noncompliance issues (49%), and it was this option that showed an improvement in construction KPIs when selected.

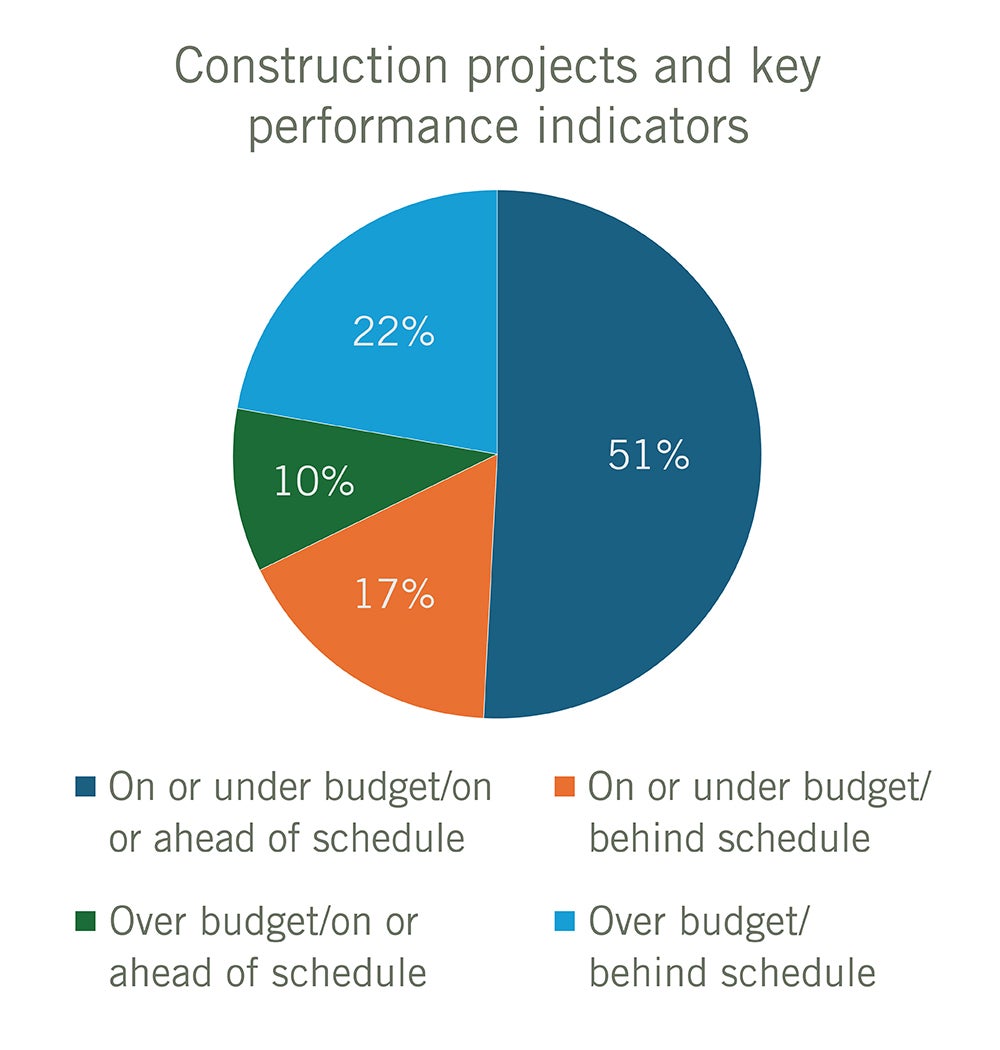

When dissecting between those who did or did not conduct mock surveys, there is a slight but noticeable difference in their construction KPI outcomes. For instance, for those who chose “conducting mock surveys” as one of their internal practices, 51% of their projects were on time/on budget, compared to 47% of projects meeting that same measurement for those who do not conduct mock surveys. Those who perform surveys prior to opening also fare a bit better in the over budget/behind schedule category. Respondents who conduct mock surveys say 22% of their projects fell below expectations for both metrics, compared to their counterparts’ projects at 25%.

Although this question on internal practices and policies was not specifically asked to prove any influence on construction KPIs, it still helps to cement a message that many in health care facilities management have long preached: that their early involvement in construction projects only serve to make the final product better. This particular data point from the 2025 survey suggests that catching issues early (preferably through virtual walk-throughs or mock-up designs, when feasible) helps ensure facilities not only are operational and survey ready on Day 1 but also make it to the ribbon-cutting on time and on budget.

Avoiding late design changes and post-occupancy modifications not only saves organizations time and money but also prevents frustration for those who work in and operate these facilities. For more, an article on page 9 of this issue shows how Valley Hospital in Paramus, N.J., used this technique when building its new, 370-bed hospital.