Transforming maintenance and embracing sustainability

Health care organizations need a proven plan with solid data that is easy to validate measurements on a continuous basis.

Image courtesy of Caltrol Inc.

Organizations have been working on energy and sustainability for many years. How have they been doing? Many have been very successful, but have they maintained their successes and performance?

The challenge with maintaining successful performance is that operations need to have this focused performance built into the facility’s fundamental operations. How does that happen? If organizations are going to achieve, maintain and continuously improve their performance, they need a proven plan with solid data that is easy to validate measurements on a continuous basis.

This is where health care asset management (HCAM) has emerged as a pivotal strategy for enhancing asset reliability and operational efficiency. The journey toward HCAM is not merely a technical transition but a profound change in culture and mindset.

This article explores how HCAM naturally integrates sustainability, envisioning a world where assets are maintained to prevent failure and support sustainability goals and performance. Through the elements of HCAM, the power of measurement in asset knowledge and performance can be demonstrated, improving the life cycle of assets to run as efficiently as possible.

Changing culture and mindset

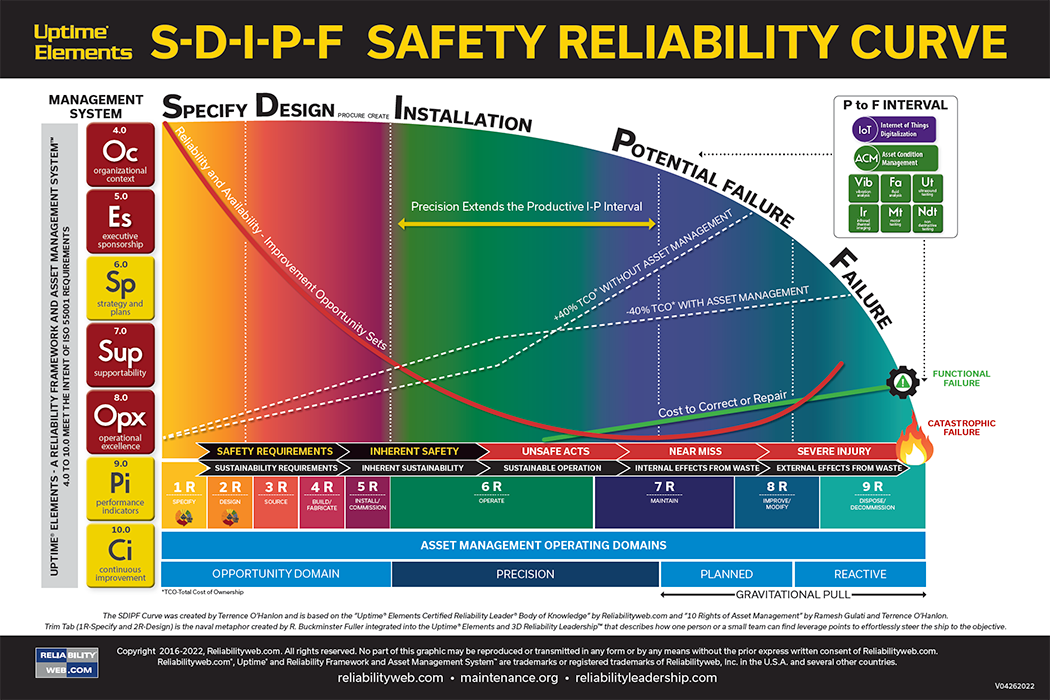

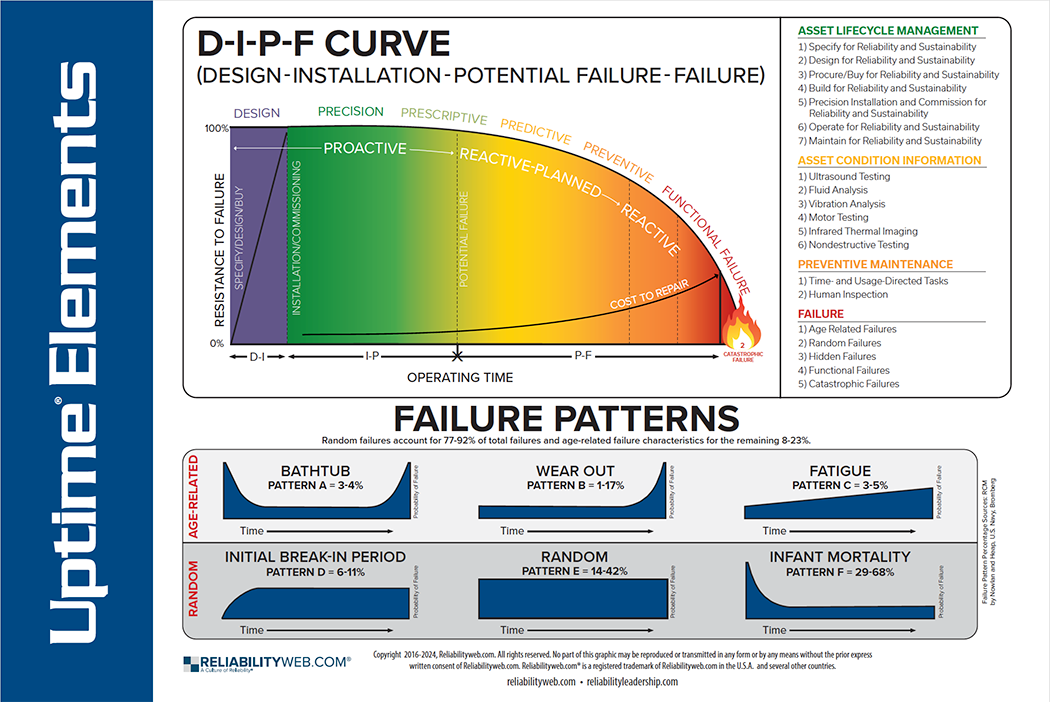

The adoption of HCAM requires a fundamental shift in how organizations perceive maintenance. Traditionally, maintenance has been time-driven, focused on consumable items and reactive, addressing issues only after they arise. However, HCAM promotes a proactive approach, focusing on preventing failures before they occur. This shift necessitates a change in culture, where maintenance is seen as a strategic function rather than a cost center. Employees must embrace a mindset that values long-term reliability and efficiency over short-term fixes.

Documenting and measuring the performance of facility systems should be a regular practice to ensure derogation and slippage in performance are known and understood.

One of the big challenges in measuring energy, water and waste performance is that most of the data used to measure them are lagging indicators, usually lagging upwards of two to three months, depending on the utility provider. This is where a shift needs to happen, with organizations using their building management system (BMS) to better inform them of their daily performance.

Often, systems are set and forgotten, assuming they will maintain their performance day after day, month after month and so on. Moving to a leading indicator with the BMS will require regular report outs from the team or system regarding key performance points, what’s running and why, whether the asset or system is meeting its functional metrics and whether there have been any adjustments or overrides since the last report out.

By looking at leading indicators, staff will be better able to spot potential issues before they become a problem and plan accordingly. Monitoring regular performance of the system is foundational and it also will bring a stronger understanding of that asset or system's purpose.

One of the key steps in the HCAM process is to review the functional performance of an asset or system as organizations work to also understand the failure modes and effects of those failures. Often, while going through this HCAM process, performance or failure modes that are not being monitored are found, which could provide valuable leading information regarding the asset or system's performance.

The implementation of condition-based monitoring (CbM), which predictively utilizes sensors and real-time data, with BMSs, fault detection and diagnostics (FD&D) or other computing analytics improves the ability to understand the performance of assets. For example, the use of existing temperature, pressure, current, position, differential pressure and temperature monitoring that is or can easily be incorporated into building automation systems allows organizations to begin to trend, analyze and predict when performance or maintenance requires attention versus the current time-based inspections and maintenance.

Another area this performance data should be feeding into is the facility condition assessment (FCA) program. CbM with the use of trending analytics and computerized maintenance management system (CMMS) maintenance records are ideal tools when it comes to identifying the FCA and when assets are functionally ready for replacement.

Sustainability in the process

One of the remarkable aspects of HCAM is its natural alignment with sustainability goals. By optimizing maintenance practices, HCAM reduces unnecessary resource consumption and minimizes waste. For instance, timely interventions prevent unexpected breakdowns and their associated environmental impacts. As organizations implement HCAM, they often find that sustainability becomes an inherent part of their maintenance processes.

According to the American Society for Health Care Engineering's Reliability-Centered Maintenance Guide, classical reliability-centered maintenance (RCM) methodology develops its risk assessment by following this seven-step process:

1. System selection and information collection.

2. System boundary definition.

3. System description and functional block diagram.

4. System functions and functional failures (preservation of functions).

5. Failure modes and effects analysis.

6. Logic tree analysis (prioritization of function needs via failure modes).

7. Selection of applicable and effective preventive maintenance tasks.

When performing the seven steps during the implementation of RCM, Step 3 requires a system description and functional block diagram, and Step 4 reviews system function and the functional failures of the asset or system. When the design, installation and expected performance of assets are documented, the operation of those assets can be ensured.

This is where the failure analysis and monitoring in RCM helps to identify a fault before it becomes a failure and understand when assets and systems are not performing as designed and installed. With today's technologies and operating systems, this is very achievable.

With the implementation of CbM and FD&D, this information can be used to ensure assets and systems are meeting their design and operating intent. This is important information that is now available to operators and maintenance professionals, allowing them to dial in their operations.

What is the chilled water temperature and the delta temperature across the air handler coils? Are buildings being over-pumped or over-cooled? The use of CbM can provide the needed data that previously only tribal knowledge and time-based preventive maintenance provided, often resulting in wasted hours and detrimental outcomes. After all, humans increase the risk of failure by 40% when they intervene.

Core principles of HCAM

At its core, HCAM aims to increase the uptime of assets and maintain operational efficiency. This approach aligns seamlessly with sustainability by reducing energy consumption and unnecessary waste. By extending the lifespan of equipment and optimizing its performance, HCAM contributes to a more sustainable industrial ecosystem. Organizations that embrace HCAM not only enhance their reliability but also make significant strides toward environmental stewardship.

This is where data and measurements need to get the horse in front of the cart when it comes to project planning, design, commissioning and FCA programs. When asset performance tracking is properly completed in and with CbM, project teams should be provided with the needed information to design and build projects with a life-cycle mindset.

This can be provided through a facilities standards document, which can include anything from approved manufacturers and products to specific installation details for equipment. A failure analysis may determine that a specific connection detail does not provide the necessary performance for the system. If the analysis identifies a change that is needed for such a connection detail, it should be documented for future use so as not to create another scenario where staff will see the same failure again.

This is an opportunity for maintenance and operations to lean in and support project teams with the data they need to achieve the best design, selection and commissioning of new assets and systems in buildings. When data is provided that informs which assets and designs are working best for maintenance and operations, everyone wins. This choice may not be the lowest first cost, but it should very well be the lowest life-cycle cost.

Another topic is the opportunity to improve the FCA programs many organizations employ. Today, most of these asset condition validations are performed by a physical visual inspection and use of time-based data for a particular asset or system. Again, this is where good CMMS data regarding maintenance performance and corrective maintenance repairs and the use of CbM can significantly support the proper assessment and condition of assets and systems.

Improved data regarding the true condition of assets and the correct timing and need for their replacements would improve organizational decisions on the proper timing for the replacement of these assets and reduce deferred replacement decisions. Repeated issues on a specific piece of equipment, even if it is not scheduled for replacement based on useful life, may indicate that it is underperforming and needs to be replaced earlier than anticipated.

This also can inform additional decisions about preferred manufacturers and installation methods, which can be incorporated back into the facilities standards document for use by future design and construction teams.

A sustainable future

Imagine a world where assets are meticulously maintained to prevent failure. Technology is used to indicate when it is time to inspect a piece of equipment, minimizing unnecessary trips and interventions. This conserves energy and reduces emissions, resulting in a more efficient and sustainable operation where resources are used judiciously and environmental impact is minimized.

Improved data informs performance, waste, energy, operation and labor. The implementation of HCAM and CbM is all about improving the outcomes of work and using data to work smarter, not harder. The seven steps in the RCM process walk through the function of an asset or system. After going through many of these steps with teams, it becomes clear that many assets and systems provide more than just their primary function, which needs to be understood and supported.

As all functions are better understood and all failure modes and their effects are identified, the best and most cost-effective maintenance that addresses those failure modes and their effects can be selected. It is important to note that an RCM does not need to be performed on every asset.

As the late Mack Smith, an internationally recognized expert on the application of classical RCM, always shared, start with the assets that are “eating your lunch!” Which assets cost the most time and money to maintain? Which assets have the highest failure risk to the operation or organization?

For example, the air handlers that support operating rooms will require a full RCM. If proper air is not provided for operating rooms, they cannot be used. The same goes for the sewer system that supports those operating rooms. While a full RCM may not be performed on that simple system, it is still necessary to understand the risk, the system and its failure modes, and what maintenance or CbM will be implemented to ensure the operating rooms are not flooded with sewage.

Another topic when it comes to the adoption of RCM with teams is the concern that this new method is a threat to their jobs. The implementation of RCM is a performance improvement process and nothing more. It is a tool and methodology that can be used to challenge the old way of doing things and put a mark on improvement and sustainability.

The implementation of RCM, CbM, FD&D and, soon, artificial intelligence enhances the work performed for improved outcomes. There is a great opportunity to shift the industry and the outcomes supported by the system in the production of work. Patient outcomes are incredibly important and should be seized to lead this improvement.

Vendor performance is another opportunity for improved sustainability. It is not always best to choose a product based on the first cost. It is important to verify with a vendor which enhancements have been made to the product. Do they have any updated data regarding failure modes of their assets or system, and how have they addressed them or recommend addressing them to ensure the greatest life cycle of the investment?

It is that old adage: pay now or pay later. Consideration also should be given to what the waste stream will look like for the asset once it is time to replace it. Purchasing a product that can be refurbished or recycled is always better than one that only goes to the landfill.

What is reliability?

Reliability is the quality of being trustworthy or performing consistently well. It is the degree to which the result of a measurement, calculation or specification can be relied upon to be accurate. Each of these definitions rings very strongly in the work accomplished and the pride taken in that work. The implementation of a performance improvement program like HCAM strengthens the work environment, processes and, most importantly, outcomes for members, organizations and the communities served. The journey toward HCAM is transformative, requiring a change in culture and mindset. As organizations adopt HCAM, they naturally integrate sustainability into their maintenance practices.

The vision of a world where assets are maintained to prevent failure is not just a possibility but a reality within reach. By focusing on reliability and efficiency, HCAM paves the way for a sustainable future, where operational excellence and environmental responsibility go hand in hand.

Related article // What does it mean to be sustainable?

Sustainability, as defined by Wikipedia, is a social goal that enables people to coexist on Earth over the long term. While the term has evolved over time and varies depending on context and literature, it is commonly understood to encompass three core dimensions: environmental, economic and social.

Among these, the environmental aspect often receives the most attention, particularly in operational settings like health care. According to the Oxford Languages dictionary publisher, something that is “sustainable” must be capable of being maintained at a certain rate or level and also must be defensible or justifiable over time. In the context of health care facilities management, this means that sustainability is not just about implementing one-time energy-saving measures or reducing water usage — it’s about embedding these practices into the very fabric of daily operations in a way that is consistent, measurable and enduring.

Organizations that have successfully integrated sustainability into their operations typically follow a structured, long-term plan. These plans are not static; they evolve through continuous improvement and are supported by reliable metrics.

In health care, where operational efficiency directly impacts patient care and safety, sustainability must be approached with precision and accountability. This is where health care asset management (HCAM) plays a critical role.

HCAM supports sustainability by ensuring that assets such as heating, ventilating and air-conditioning systems, medical equipment and lighting are maintained and operated at peak efficiency throughout their life cycle. Through data-driven asset management, facilities can track performance, identify inefficiencies and make informed decisions that extend asset life and reduce environmental impact.

Ultimately, sustainability in health care is about more than compliance or cost savings. It’s about creating resilient, high-performing environments that support both patient outcomes and community well-being.

By aligning asset management strategies with sustainability goals, health care organizations can uphold their mission while contributing to a healthier planet.

Gregory Hudson, PE, CHC, HFDP, is a principal and project manager for RMF Engineering Inc.’s Charleston, S.C., buildings team; Dave Lockhart, CHFM, CEM, FASHE, is executive director of facilities operations and maintenance for national shared service operations at Kaiser Permanente, Oakland, Calif.; and Terrell Estes, CHFM, CEM, is national project manager at Kaiser Permanente. They can be reached at gregory.hudson@rmf.com, dave.lockhart@kp.org and terrell.f.estes@kp.org.