Using KPIs to drive results

A construction team seeking to tune up its impact with key performance indicators may start by defining its top four or five core outcomes.

Image by Getty Images

Health care facilities teams have more data than ever. But without the right key performance indicators (KPIs) used the right way, the data is little more than distracting noise.

KPIs can unify teams, prioritize where support is needed and achieve outcomes more smoothly.

By understanding common KPI drivers, learning to navigate pitfalls and adopting processes for operational and strategic use, a facilities team can take their impact to the next level with less stress.

Drivers for KPIs

KPIs are a short list of the most important numbers that boost outcomes when tracked regularly. Developing and using effective KPIs fosters several elements of a stronger team working with greater purpose. These elements include:

Teamwork. Knowing desired metrics and why they are important helps to rally a team. When the numbers are off track, individuals are drawn to solve problems. Also, when a new goal is set, a strong team will want to rally to achieve it.

Accountability. Numbers create a clear understanding of what is expected. Knowing a target allows team members to ask for help when they are falling behind and alerts managers to offer support when they see performance lagging.

Early intervention. KPIs predict future outcomes and give early warnings on where to shift an approach or add resources before outcomes slide and goals are missed.

Quicker feedback. KPIs create near-term feedback when shifts in approach are taken. They shorten the cycle time between interventions to get to the right solution faster.

Clarity. In a busy world of many priorities, having the right KPIs helps to provide support where it is needed. Rather than “doing more with less,” KPIs help teams “do better with the same resources” by knowing where supportive actions are most needed.

Pitfalls to avoid

Understanding common pitfalls to avoid sets the table for more effective selection and use of KPIs. These pitfalls include:

- Confusing KPIs with benchmarks. Important data that are relatively static and used to justify resource needs are called benchmarks or metrics. For example, Environmental Protection Agency ENERGY STAR® scores prioritize which buildings in a system should be selected for retrocommissioning and facility condition indices guide where capital renewal is needed. These numbers, however, are not meant to guide day-to-day “in-flight” decisions and should not be confused with KPIs.

- Sampling too infrequently. KPIs need to be reported frequently enough to allow shifts in approaches or processes before it is too late to reach a desired outcome. A best practice is to report on KPIs when a functional team meets, usually weekly or biweekly.

- Addressing the wrong outcome. Care should be taken to determine the true outcome that is needed; otherwise, the wrong destination may be reached. Regarding productivity, for example, a front-line worker may be completing the most work orders per day but skipping harder work orders for the most critical equipment, which could lead to compliance issues.

- Data quality. Missing information can make the results of an indicator misleading. The number of overdue preventive work orders is more meaningful if filtered by equipment criticality. Likewise, the amount of contingency funding remaining on a project is meaningless if facilities teams don’t know the percent complete or the percentage of risk remaining.

- Choosing too many KPIs. If everything is important, nothing is important. Trying to track and manage too many numbers will lead to an inability to identify and respond to priorities. If a KPI is not being reviewed and discussed in a standing meeting, it should not be on the list. Good practice is for each KPI to have a clear owner, and nobody should own more than three to five KPIs.

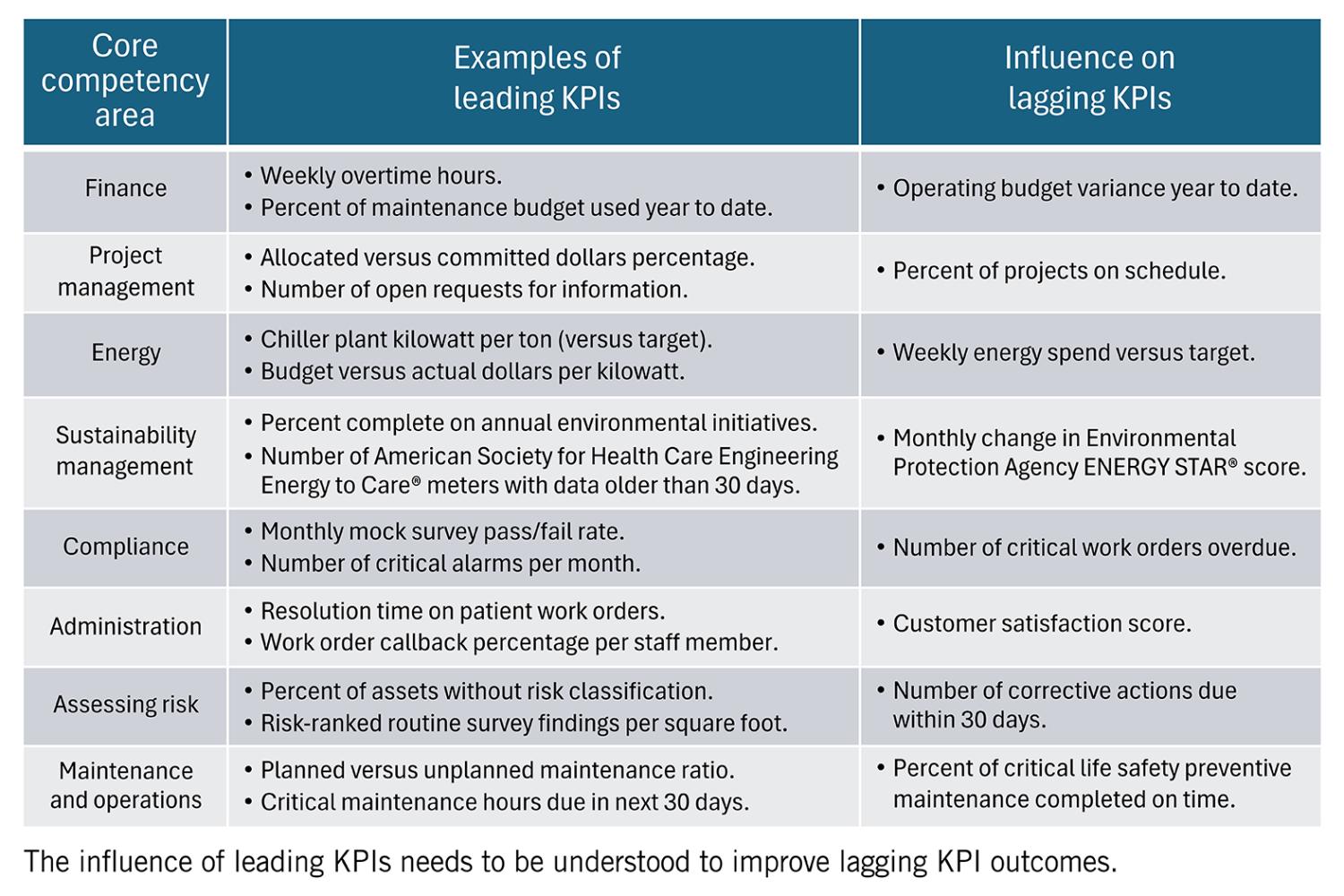

Launching operational KPIs

Operational KPIs report back real-time progress on work that is core to a team’s role. They help focus day-to-day resources where issues are occurring. They demonstrate transparency, promote accountability and appraise how well stated objectives are being achieved. Steps to develop and apply KPIs for improved outcomes include:

- Define the top outcomes of a team being analyzed. Health care facilities teams have many responsibilities, but the outcomes that matter most up the chain of command should be selected first. It will be impossible to address all functions of the team in the first pass. For example, a facilities management team may have the following top outcomes: high readiness, consistent compliance, fiscal sustainability and satisfied customers.

- Identify numbers that capture each outcome. These numbers are known as lagging indicators and can be thought of as a rearview mirror looking back on where the team traveled and whether they arrived at the correct destination. It is helpful to imagine that the team leader is away on an extended trip but is available two hours a week to help the team troubleshoot issues. They only can get a short message each week from the team and need status on a handful of numbers to know which roles are doing well and where their limited support is needed. For example, under the outcome of high readiness, the KPI might be the number of critical work orders past due; when such work orders lapse, they create safety and accreditation concerns.

- Add predictive KPIs known as leading indicators. Once the lagging indicator KPIs are established, consider which numbers predict hitting that outcome. A shortfall in a current leading indicator will likely show up as a shortfall in a future week’s lagging indicator. Again, considering the team outcome of high readiness, a leading indicator to predict future overdue critical work orders could be the number of weekly preventive labor hours scheduled per person; if the team is over-allocated, they will have a hard time completing the work. Another leading indicator could be the planned-to-unplanned maintenance ratio; an uptick in unplanned maintenance is an early warning that there could be a bottleneck of planned maintenance ahead.

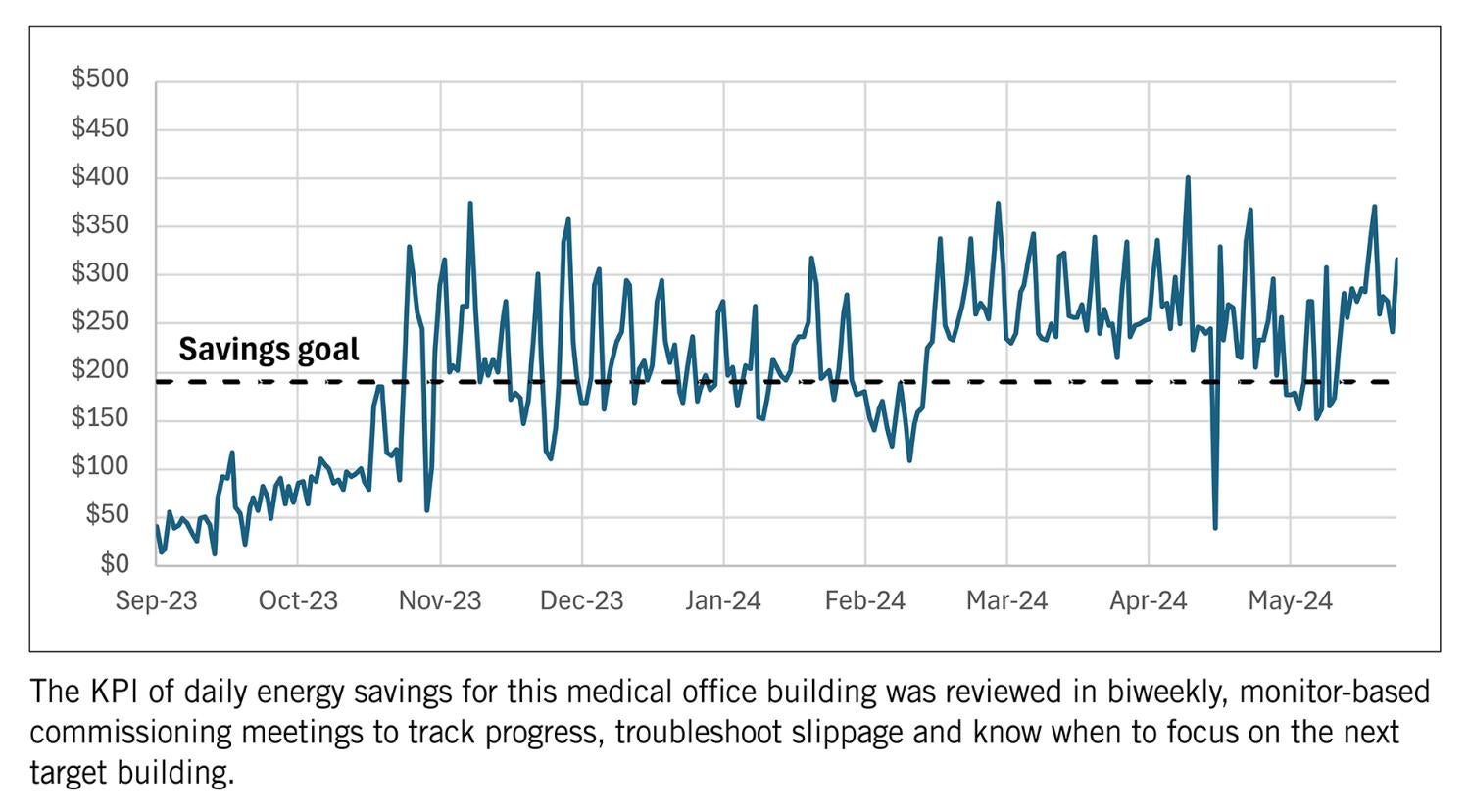

Start tracking KPIs and troubleshoot regularly. Facilities managers shouldn’t worry about slick presentations or software integration. Instead, they should start by maintaining a simple table of the KPIs with a row for each reporting period, ideally weekly.

KPIs must be top of mind to bring the most benefits. KPI review should be a regular agenda item in one-on-one meetings between supervisor and employee as well as in functional team or department meetings. Reviewing the KPIs should prompt discussion around what interventions can be done to better achieve targets and to troubleshoot root causes if KPIs begin to slip.

If review of the KPIs in standing meetings does not prompt troubleshooting discussion or action items, they are probably the wrong KPIs and should be reevaluated.

Under the team outcome of fiscal sustainability, a hospital’s energy team might report a leading indicator of “daily savings from baseline” in their weekly monitor-based commissioning program meetings. Seeing the savings dip two weeks in a row would prompt investigation to find a root cause, such as building automation system overrides needing correction, well before the lagging indicator of utility savings has accrued in budget variance reports.

Shift input actions to impact KPIs. Tracking KPI data isn’t just about having data; it’s about improving outcomes. As such, once KPIs are being tracked, interventional activities should be developed to have a positive impact on the KPIs that are not meeting their desired targets.

These shifts could be routine and process oriented — such as simplifying the steps to do an activity so that goal attainment is more consistent. They also could be episodic, such as providing refresher training. Lastly, there may be barriers that are standing in the way of attainment and require resources to be removed.

Under the team outcome of consistent compliance, for example, a reduction in weekly excursions in humidity and a resulting reduction in weekly unplanned compliance labor and reporting may be achieved by adopting a ventilation management plan that uses a risk assessment to expand the time duration before an event classifies as an excursion.

Shorter-term KPIs

Standing apart from operational KPIs that are measured routinely, strategic KPIs are used to measure progress toward time-bound strategic goals. They are tied to a concerted effort to improve a specific outcome and are generally used for a finite time.

Many health care organizations are now requiring capital requests to include an action plan, such as those using a “situation, background, assessment and recommendation” or A3 process.

Requests are scored based on the KPIs that will be used to measure impact if the project is funded. Gaining practice with strategic KPIs will help increase the likelihood of funding requests being approved.

In other instances, leadership will ask for involvement in a strategic initiative, such as an effort to improve patient satisfaction scores or a campaign to improve employee engagement scores.

Construction example

An example of this process might be a facilities construction team that seeks to tune up its impact and starts with defining its top four or five core outcomes. In this case, the team selects budget adherence, schedule attainment, stakeholder satisfaction and resource efficiency.

To decide where to apply strategic KPIs, the team ranks issues that are impacting outcomes under the key outcomes of the team.

For example, budget adherence and schedule attainment are impeded by project managers not consistently using the project management software. In the area of stakeholder satisfaction, conflicts between project managers and facilities operations are common. Lastly, when it comes to resource efficiency, project initiation requests are exceeding the capacity of the facilities construction team, leading to extended wait times and user group frustration.

The facilities construction team decides to tackle the problem of inconsistent project management software use as a starting point, so there will be bandwidth to tackle other issues if projects in the pipeline are running more smoothly.

The team identifies several root causes limiting the depth and consistency of the project management software use. Interventions are planned to navigate those barriers, including:

- iPads are provided to make field documentation easier.

- Features are turned on to increase the preventive maintenance tasks that can be performed in the software.

- Form fields are simplified to make updates easier.

- Demonstrations are recorded to serve as refresher training.

- A rallying goal of 80% of projects being on or ahead of schedule by the end of the next fiscal year is created.

Next, the team establishes three leading indicators to serve as predictors of improved schedule adherence and monitor progress — number of logins per week per project, open issues older than two weeks and number of overdue tasks.

The lagging indicator is set as the number of milestones achieved early with a target of 80% being on schedule.

Because regular project meetings occur biweekly, the team sets up the four KPIs to be recorded automatically in the software every two weeks, with all projects rolled up into combined KPIs and filtered by project manager.

A monthly newsletter celebrates progress on the KPIs. Project managers share lessons learned from problem-solving in the monthly department meeting. Lastly, the team leader obtains funding to enter all projects that have at least three milestones on time or early into a drawing for a quarterly project team barbecue.

At the end of the one-year tuneup, the team has improved dramatically from its baseline, and project managers who have tough projects are getting more support early when it makes the most difference. Half of the KPIs stick around as operational KPIs, and the other half are determined to be no longer necessary.

An effective tool

KPIs are effective tools to improve teamwork, boost accountability and provide the right support in the right place early enough to make a difference.

Related article // Working with Lean experts within a health care organization

When it comes to key performance indicators (KPIs) and process improvement, no one in health care knows the topic better than a Lean team. This office houses internal experts on process improvement who work across all business units and clinical disciplines, yet very few health care facilities teams have collaborated with them.

The analysts on the Lean team generally have a high degree of curiosity and troubleshooting skills. They are not experts in any technical or clinical discipline, but they are masters of applying process improvement techniques to any problem.

Their breadth of knowledge and experience consulting with others can act as an accelerator to a budding KPI program within the health care facilities team.

They also are accustomed to working on problems that matter to executive leadership. This relationship can add visibility and significance to work within facilities, make connections with the organization’s strategic priorities and increase access to resources. When leadership wants to do something, it often happens.

The first step is to find the Lean team. Nearly every health system has one — perhaps several. They can go by many names: Lean, quality, decision support, continuous improvement and business transformation are common keywords to look for.

Going to lunch or coffee with anyone from the Lean team who is willing can be an effective way to test the waters and find allies. Facilities managers can find out what the Lean team is working on, what they are excited about and what problems they are most attuned to. They should provide context on the opportunities for process improvement within facilities, such as eliminating waste or optimizing workflow.

Once allies are identified, facilities managers should inquire about the procedure to request their involvement in a project. They should select a situation in which it feels like a magic wand is needed for improvement, such as elimination of service calls performed without a work order, reduction in backlog of planned maintenance or gaining funding for an internal commissioning employee.

Process improvement itself is a process, and the best way to improve is to get started!

Kevin Gombotz, PE, is president at Envinity Inc. in State College, Pa., and Gainesville, Fla. He can be reached at kgombotz@envinity.com.