Traffic stopper

Project specs

Project Florida Hospital Memorial Medical Center

Location Daytona Beach, Fla.

Number of square feet 736,000

Number of floors 12

Number of beds 277

Construction cost $170 million

Project cost $270 million

Start date August 2006

Opening date July 2009

Team Members

Owner Florida Hospital Memorial Medical Center

Architect HuntonBrady Architects

General Contractor Robins & Morton

Environmental Consulting Professional Service Industries Inc.

Interior Design and Medical Equipment planning Parsons Corp.

MEP Engineering TLC Engineering for Architecture

Structural Engineering Walter P Moore

Landscaping HHI Design

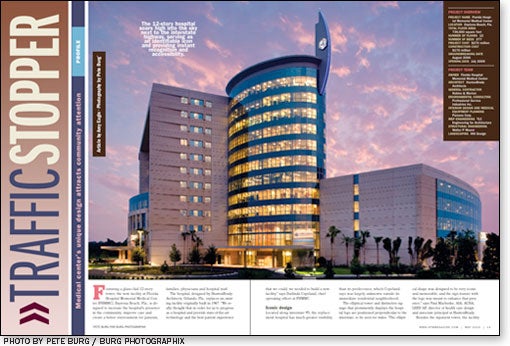

Featuring a glass-clad 12-story tower, the new facility at Florida Hospital Memorial Medical Center (FHMMC), Daytona Beach, Fla., is designed to increase the hospital's presence in the community, improve care and create a better environment for patients, families, physicians and hospital staff.

The hospital, designed by HuntonBrady Architects, Orlando, Fla., replaces an existing facility originally built in 1967. "We really thought that in order for us to progress as a hospital and provide state-of-the-art technology and the best patient experience that we could, we needed to build a new facility," says Darlinda Copeland, chief operating officer at FHMMC.

Iconic design

Located along interstate 95, the replacement hospital has much greater visibility than its predecessor, which Copeland says was largely unknown outside its immediate residential neighborhood.

The elliptical tower and distinctive signage that prominently displays the hospital logo are positioned perpendicular to the interstate, to be seen for miles. "The elliptical shape was designed to be very iconic and memorable, and the sign feature with the logo was meant to enhance that presence," says Paul Macheske, AIA, ACHA, LEED AP, director of health care design and associate principal at HuntonBrady.

|

| Orientation and wayfinding are simplified in the grand, three-story lobby and public concourse that connects inpatient and outpatient services. |

Besides the inpatient tower, the facility includes a three-story diagnostic and treatment block and a medical office building that adjoins the hospital.

The entire facility is designed to create a calming, noninstitutional, wellness-focused impression, says Chuck Cole, AIA, ACHA, health care design principal and president at HuntonBrady.

The three-story atrium lobby sets the tone for the building with stone floors; an expansive, wood-paneled wall; and a view into the hospital's healing garden. Custom lighting is inset into the lobby wall to create a soft glow at night.

Healing environment

During the day, the building is filled with natural light, from the atrium to areas that do not commonly see the light of day in health care facilities, such as the same-day surgery department and the post-anesthesia care unit.

"People who work in the OR or in the recovery room typically work in a space with no windows at all. We made sure those kinds of areas had access to windows, so the staff has access to natural light. That really has helped with the morale of our staff," Copeland says.

Lounges for staff and family members are located on each patient unit at the far end of the curved inpatient tower, which has unobstructed exterior views. In the patient rooms, floor-to-ceiling windows provide access to abundant natural light. "There's a lot of research out there about natural light and providing a healing environment," Copeland says.

Many patient rooms also feature a view window so nurses can monitor patients closely when necessary.

According to Copeland, the Florida Agency for Healthcare Administration, a state licensing and regulatory agency, requires view windows for intensive care units only, but the hospital included them in many other patient rooms as a safety measure. A nurse seated at a workstation between two rooms can maintain a view of two patients at once.

A large number of hand washing sinks were installed to help prevent the spread of infection. Sinks are located in every patient care area, from inpatient rooms to ambulatory surgery bays. "Wherever there is a patient space, there is a sink," says Copeland. "That was really important to us when we built the facility."

Process flow

The hospital departments are organized for optimal process flow. The third floor cardiovascular department, for instance, includes all necessary services for cardiovascular patients in one location. Patients are prepped, see their physician and go straight to a procedure room. "They never go to a holding area because we find that the more handoffs you have from staff member to staff member, that's a chance for medical error," says Copeland.

|

| Labor-delivery-recovery-postpartum rooms include high end finishes and equipment for infants that is concealed behind the artwork headwalls. |

The admission area, catheterization lab, endovascular operating room, heart surgery suite, cardiovascular intensive care and step-down unit are aligned in a counter-clockwise fashion, so patients never have far to travel, especially in an emergency.

Each of the 53 beds in the emergency department has monitoring capabilities for an intensive care patient. Three of these are reserved for trauma and seriously ill patients; the rest can be assigned to any patient without regard to acuity. As a result, the hospital is able to maintain a five-minute limit from when a person signs in to when he or she is placed in a treatment bay.

The ED nurses' station is positioned with clear sight lines to the ambulance and pedestrian entrances. The department is horizontally aligned with the imaging department and laboratory, and vertically aligned with the surgical, cardiovascular and birth care centers. Patients can be taken quickly to the appropriate care area.

All of the hospital's operating rooms are a spacious 600 square feet, to provide room for specialty equipment and large surgical teams. Soft space in the large central sterile core can later be used to create larger ORs or additional control spaces for imaging environments within the surgical suite.

'Design does matter'

Since the new hospital opened, Copeland says physicians who had left the old facility have come back, both because they wanted to work in the new environment and because their patients encouraged them to practice there.

Patient satisfaction scores, as measured by the national Hospital Consumer Assessment of Healthcare Providers and Systems survey, have risen to the 90th percentile.

"It's evidence that design does matter," Macheske says.

Amy Eagle is a Homewood, Ill.-based freelance writer and a regular contributor to Health Facilities Management.

| Sidebar - Cost-conscious design leads to operational efficiencies |

| The new facility at Florida Hospital Memorial Medical Center was designed to be efficient both to build and to operate. Despite being built during a time of double-digit construction price escalation, the project was completed for about $70 less per square foot than the average price of hospital construction in the United States, according to project architects. Some of these savings were realized through the use of a precast concrete exterior. This material was chosen for its speed of erection and constructability, as well as its long-term durability. The hospital's compact footprint also accounts for much of the efficiency. The building has a low skin-to-floor ratio, meaning there is little exterior wall per square foot of building area. This creates a very efficient floor plate. Additionally, each of the floors in the hospital's 12-story tower is laid out the same, which made them more economical to build. The electrical and communications rooms and other mechanical spaces are stacked above one another for greater efficiency. "As architects, we had to understand high-rise building codes and how to design efficiently in a high-rise environment," says Paul Macheske, AIA, ACHA, LEED AP, director of health care design and associate principal at HuntonBrady Architects, Orlando, Fla. The building efficiencies dovetail nicely into operational efficiencies for the hospital. The compact footprint results in shorter walking distances for nurses; the identical floor layout enables nurses to work on various floors of the hospital without having to learn a new layout for each. The building was designed and built to allow for future efficiencies, as well. The hospital's diagnostic and treatment block is currently three stories tall but can accommodate up to eight stories, for 300 additional beds. Two shelled floors at the top of the inpatient tower will hold another 72 beds. "The owner received a worthwhile investment in the future," Macheske says. |

| Sidebar - Scheduling allows for latest in imaging technology |

| To provide the latest in patient care and make the most of a significant, long-term investment in high-tech medical equipment, hospitals need to make purchasing decisions for the radiology department as close to the opening of a new facility as possible. But designers and building professionals need final equipment specifications to complete their work. To ease this inevitable tension at Florida Hospital Memorial Medical Center (FHMMC), the first floor radiology department was left unfinished until about six months before the hospital opened. "We basically built a temporary wall around the radiology department area, left the concrete floor slab unpoured and coordinated all the infrastructure around it," says Angel Colon, project manager from the Orlando, Fla., office of construction management firm Robins & Morton. The builders provided utility services to other areas as construction progressed. Because construction spanned nearly three years, the hospital gained a substantial amount of time for equipment selection. The out-of-sequence work required careful planning and coordination. The main trunks of ductwork, major utilities and medical gas lines were stubbed out for later connection. Moisture in the area was monitored and controlled to ensure the open slab did not affect finishes in the rest of the facility. Some of the excavation was completed by hand or mini-excavator. Robins & Morton used previous experience, generic vendor drawings and cost escalation projections to establish a construction budget in the absence of specific vendor drawings and specifications for the major radiology equipment. They scheduled all work with the owner, architect and subcontractors to allow time for the final design, engineering, state approval and construction process to be completed once the equipment was selected. Darlinda Copeland, FHMMC's chief operating officer, says this approach enabled the hospital to buy the latest equipment to serve the community, including a 64-slice, dual-source computed tomography scanner. |

| Sidebar - SPEC SHEET |

| Principal Design Materials Carpet and carpet tile: Interface Inc. Ceiling: Armstrong World Industries Inc. Curtain wall framing and glass: Harmon Inc. Door hardware: Schlage Doors: Algoma Hardwoods Inc. (wood) and Kawner (aluminum) Flooring: Armstrong World Industries Inc. (sheet vinyl and vinyl composition tile) and Daltile (granite and porcelain tile) Lighting: Philips Lightolier Paint: PPG Industries Plumbing accessories: Chicago Faucets, Elkay Manufacturing Co. and ProFlo Plumbing fixtures: Kohler Co. Roofing: Soprema Inc. Signage: ASI Sign Systems Inc. Wall coverings: D.L.Couch Window treatments: MechoShade Systems Inc. Principal Furnishings Cafeteria seating: Source International Corp. Cafeteria tables: HON Conference tables: HON and Knoll Inc. Headwalls: Modular Services Co. Lounge and patient room seating: Krug Office desks, files and shelving: Knoll Inc. Office seating: Stylex Patient beds and over-bed tables: Stryker Major medical equipment Computed tomography and catheterization laboratory: General Electric Co. and Siemens Corp. Magnetic resonance imaging and cytoscopy: Siemens Corp. Radiation/fluoroscopy: General Electric Co. Sterilization and operating room lights/booms: Steris Corp. Cardiovascular operating room lights/booms: Stryker Infrastructure Boilers: Cleaver-Brooks Inc. Building management system: Siemens Corp. Chillers: York by Johnson Controls Electrical equipment: ASCO Power Technologies and Schneider Electric Elevators: Schindler Management Ltd. Fire safety: Firetrol Protection Systems Inc. (fire pump controller), Peerless Pump Co. (fire pump) and Siemens Corp. (fire alarm) Generator: Caterpillar HVAC (misc.): Busch (vacuum pump), Evapco (cooling towers), Enviro-Tec by Johnson Controls (terminal units), Powerex Inc. (medical air compressor), Veeder-Root Company (fuel oil management) and York by Johnson Controls (air handling units) Nurse call: Hill-Rom Pneumatic tube: Swisslog Security: IDenticard Systems and Rauland-Borg (infant security) Information provided by HuntonBrady. |